We hear every day about the importance of conserving energy and the increasing need to use renewable natural resources. To help educate people on ways to “go green,” various organizations sponsor events which display and explain unique ways one can conserve energy while maintaining an otherwise normal life. One such event is the Solar Decathlon.

Solar Decathlon

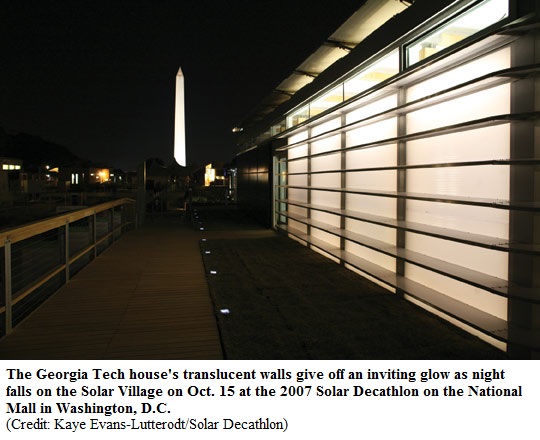

Sponsored by the U.S. Department of Energy, the 2007 Solar Decathlon was held on the National Mall in Washington, D.C., in mid-October. This competition featured twenty teams from around the world and emphasized the creation of attractive, energy-efficient and completely solar-powered homes. One of the homes was designed and constructed by faculty and students of GA Tech’s College of Architecture, and the College of Engineering and Sciences. Georgia Tech’s solar-powered house placed 6th after the week-long competition during which the house was judged in a series of 10 competitions: architecture, engineering, market viability, communications, comfort “zone”, appliances, hot water, lighting, energy balance, and “getting around” (maneuverability).

Sponsored by the U.S. Department of Energy, the 2007 Solar Decathlon was held on the National Mall in Washington, D.C., in mid-October. This competition featured twenty teams from around the world and emphasized the creation of attractive, energy-efficient and completely solar-powered homes. One of the homes was designed and constructed by faculty and students of GA Tech’s College of Architecture, and the College of Engineering and Sciences. Georgia Tech’s solar-powered house placed 6th after the week-long competition during which the house was judged in a series of 10 competitions: architecture, engineering, market viability, communications, comfort “zone”, appliances, hot water, lighting, energy balance, and “getting around” (maneuverability).

Of course, such a big project requires teamwork. Joe Jamgochian, a recent architecture graduate and co-leader of the construction project, relished the opportunity to work in close collaboration with university professors, engineering students, and specialists in the construction industry. He was particularly proud of the team’s work ethic. “There’s been a real commitment by a core group of students and faculty to take individual responsibility for our project as a whole,” he says. “They think of the potential issues ahead [of time] and address them.”

The 700-square-foot house, named “Icarus” from Greek mythology, was first constructed on the GA Tech campus. Once completed, it had to be dismantled and transported to Washington, D.C., where it was erected with the other entries in a “solar village” set on the National Mall.

Getting to the Solar Decathlon

The road to the Solar Decathlon was a long one. During the summer of 2006, faculty in the College of Architecture joined forces with faculty in the College of Engineering and Sciences to lead a five-week Interdisciplinary Design Workshop to set the basic design parameters for the house. At the conclusion, the schematic design package including architectural design of the house, preliminary energy and economic analysis, and material and product research was submitted to the U.S. Department of Energy’s National Renewable Energy Laboratory (NREL).

Through generous investments of many local sponsors, fundraising efforts began to yield material deliveries beginning in October. “Team sponsorship meant everything,” said Project Manager Chris Jarrett. “It enabled Georgia Tech’s team to get the job done, to be creative and competitive; it enabled them to pursue state-of-the art sustainable design and technology integration.”

Team Icarus focused the fall of 2006 on testing the house’s design through a variety of real and simulated operations. This required extensive quantities of drawings and construction of large-scale models, including 1:1 mock-ups of sections of the wall and roof of the house. Students coordinated the design of the chassis, as well as worked out logistics associated with the construction and transportation of the house.

In spring 2007, the team attended an NREL-sponsored Solar Decathlon meeting in Washington, DC. The remainder of the spring term was devoted to completing construction documents, and finishing extensive shop drawings associated with the various custom parts of the house; while maintaining the highest levels of safety, major emphasis was placed on organization of the construction process.

For Team Icarus, the summer of 2007 was consumed with construction of the house, with the goal to finish the house on time and under budget. For a high-performance building of this nature, that’s a tall order. Actual project costs for each team typically exceeded $600,000. Cutting, gluing, bolting, shaping materials and carefully assembling the various parts of the house, the team continued construction into the fall semester. As the finishing touches were applied, engineering students spent long hours testing and monitoring various control systems throughout the house.

Once completed, the team turned its focus on successful transportation of the house to the National Mall in Washington, D.C. There students had to assemble the house within a few days before opening to the public and the start of the 10-event competition.

The Icarus Design

Icarus is designed to harness and celebrate the power of sunlight. Through various media, the students are bringing in the sun by experimenting with light to see how it can transform and open up living space. “We’ve placed a great emphasis on light and bringing light into the house in unique ways,” says Jason Mabry, a recent architecture graduate and co-leader of the construction project. “Visitors will be able to see how the house works within itself. They’ll see all the technologies we’re putting into the house to make it more livable and efficient.” And what a house the team has designed.

The starting point was radically rethinking a basic roof design. To avoid complete opacity, the use of an innovative material was proposed where the sun’s rays meet the building’s upper most skin, By incorporating ethylene tetrafluoraethylene (ETFE), an inventive roof assembly was engineered to control and channel greater amounts of light within the interior of the building. Built of a series of insulated plastic films, the roof skin is primarily an assembly of semi-transparent layers held together by wood and steel mullions. The 14’x48’ house is segmented structurally into nine bays with ETFE integrated into this organizing geometry. Conceived as nine pillows, the roof is a landscape of light transmission.

Icarus’ main energy collector is the solar array. Designed to perch over the roof, a matrix of 27 solar panels, individually supported using custom made wing-like figures, is comprised of both a photovoltaic (PV) panel and a shading device to insure 100% shading of the roof. Mounted on an adjustable rack, the wing-like figure can be rotated to the optimal solar angle, while the shading device can be calibrated to maximize or minimize solar heat gain.

The ETFE roof panel material is a light-weight, double translucent film which allows diffused light to pass through while maintaining its opacity and thermal efficiency.

Each panel is inflated like a pillow and filled with aerogel insulation. The lightest substance known, aerogel is a solid-state material, derived from gel, in which the liquid component of the gel has been replaced with gas. The result is an extremely low density solid with several remarkable properties, most notably its effectiveness as an insulator.

This roof design provides 6.5 KW of electricity to power the energy systems and appliances of the house. A portion of the south wall contains 12 PV panels to provide an additional 2.0 KW of electricity to help power the house and an electrical vehicle.

Rainscreens, used on the roof and on the south wall, are ventilated cavities which utilize wind pressure to dissipate the energy of driven rainwater. As a result, rainscreens prevent the premature decay of building materials in homes due to moisture intrusion.

Just below the roofline, a row of small windows wraps the perimeter of the house providing additional daylight and panoramic views of the sky from inside the house.

As part of the outdoor landscape, easily installed evacuated tubes convert the sun’s energy for heating water. Each evacuated tube consists of two glass tubes separated by a vacuum. The vacuum helps retain heat from the sun. The insulation properties show that while the inside tube may be 150°C / 304°F the outer tube remains cold to touch. As a result, evacuated tube water heaters can perform well even in cold weather. A set of 20 glass tubes provide all the domestic hot water needed for the house.

The solid walls of the house are composed of factory-made structurally-insulated panels (SIPs) composed of energy-efficient expanded polystyrene insulation. SIPs on the west and north walls are finished with “light gauge” metal panel siding.

A split heat pump provides individual control of air-conditioningfor different spaces in the house without ductwork. The outdoor unit is connected to the inside fan coil units by small refrigerant lines cycling refrigerant to heat or cool the air inside the house. Its slow cooling mode also allows users to control humidity in the house.

A split heat pump provides individual control of air-conditioningfor different spaces in the house without ductwork. The outdoor unit is connected to the inside fan coil units by small refrigerant lines cycling refrigerant to heat or cool the air inside the house. Its slow cooling mode also allows users to control humidity in the house.

An energy recovery ventilator (ERV) conditions incoming air using the temperature and humidity of the outgoing exhaust air from the house. An energy wheel rotates within the ERV unit and transfers the energy of the exhaust air to the incoming air. This easy-to-install, off-the-shelf technology reduces air-conditioning energy consumption by recovering what would otherwise be wasted.

Icarus is controlled by software which continuously assesses solar power available against energy demands of the house. The software not only predicts energy balance over the next week, but also warns the user about expected operation of the house when solar power is limited.

The interior of the house demonstrates the integration of LED and fluorescent light technology for ambient lighting in residential applications. Extremely energy efficient, LEDs last up to 25 times longer than traditional incandescent light bulbs. LED flood strips are integrated into the design of the walls in the bedroom, producing a luminous effect that can be dimmed to suit one’s lighting demands. Fluorescent lighting is also more efficient than incandescent light. The living areas of the house use fluorescent lighting modulated by zoned light circuits.

Solar technology is also showcased in this house at night. Small solar lights, self-sufficient with their own battery, line the outdoor deck. These small lights charge with solar energy during the day and provide outdoor deck lighting at night.

In the area of water conservation, Icarus’ water management system collects rainwater from the roof, the sinks, and air conditioning, and channels it to a storage tank in the garden for gray water use in the house’s energy systems and for the indigenous plants around the deck.

Team Icarus designed their solar house to operate efficiently and economically over the long term. The open plan is filled with abundant natural light; durable, low-maintenance, easy-to-clean surfaces enable the homeowner to perform everyday living tasks with a minimum of effort and a maximum of safety.

Sustaining life with light, the house is accessible to the most rapidly growing population – mid-life, empty-nesters who desire an adaptive living environment. The interiors of the house

have been designed to facilitate movement and address issues of physical impairment.

“We tried to create a house that could grow with people,” said Amanda Cook, an architecture graduate student. “It is a very accessible house with an open floor plan, (low) countertop height in the kitchen, low appliances, and three exit doors and ramps.” The bathroom features a roll-in shower to accommodate wheelchairs. Additional features include adjustable shelving, accessibility under work areas, navigation lighting at night, and a high level of evenly-distributed natural daylight. Houses designed for accessibility help people continue living independently in their homes longer.

After the week-long decathlon competition, the house was dismantled and returned to the GA Tech campus in Atlanta, where it is now open for public viewing. Those interested in touring Icarus can visit www.coa.gatech.edu for open hours and directions.

Source material contributed by Georgia Tech College of Architecture

2007 Solar Decathlon photos by Kaye Evans-Lutterodt/Solar Decathlon

By TJ Johns

AutomationDirect

Senior Editor

Originally Published: June 1, 2008