When choosing a photoelectric sensor for an application there are many things to consider. One of these considerations is whether to select a light-operate or dark-operate photoelectric sensor. The terms “light-operate” and “dark-operate” refer to when the sensor activates its output.

For a light-operate sensor (also called light-activated, light-on, or simply L.O. sensor), the output will be actively true when it sees light reflecting into the sensor’s receiver circuit. With a dark-operate sensor (similarly also called dark-activated, dark-on, or simply D.O. sensor), the output will be actively true when it doesn’t see light reflecting into the sensor’s receiver circuit. This is different than whether the output is a normally open or a normally closed circuit.

Light-operate and dark-operate sensor modes can function differently depending on the sensing style of the photoelectric sensor. There are three basic sensing styles available for photoelectric sensors – diffuse (with and without background suppression), retroreflective, and through-beam.

A diffuse photoelectric sensor works by sending light out of its emitter circuit (which is within the same housing as the receiver) and if an object enters the field of this emitted light, a portion of light is reflected back into the receiver circuit of the sensor. Thus when an object is in front of the light beam emitted by a diffuse photoelectric sensor, the sensor is seeing light. Otherwise, when no object is preset, the sensor is detecting a “dark” condition. If the sensor is a light-operate sensor and an object is in front of it, the output circuit of the sensor will change to actively true. If the sensor is a dark-operate sensor and an object is in front of it, the sensor will see light and the output will go from actively true to actively false. Meaning for a dark-operate diffuse photoelectric sensor, the output will be true when nothing is in front of the sensor.

Through-beam photoelectric sensors and retroreflective sensors work identically in terms of the light-/dark-operate modes but the opposite of a diffuse photoelectric sensor. A through-beam photoelectric sensor has two separate components, an emitter and a receiver. The emitter of a through-beam sensor emits light and the receiver will receive the light and determine the output circuit state. The emitter and receiver need to be installed across from each other so that the receiver will see the emitted beam. For a light-operate through-beam photoelectric sensor, the output will be true when nothing is blocking the light beam and the components are aligned properly. For a dark-operate through-beam photoelectric sensor, the output will be true when it sees a “dark” condition, which can mean the light beam is blocked or the emitter and receiver are out of alignment.

Retroreflective sensors operate similarly to a through-beam but instead of two sensor components for the emitter and receiver circuits, both circuits are contained in one unit. However, a reflector needs to be mounted opposite of the sensor and the sensor needs to be aligned properly with this reflector. Just like a through-beam sensor, a light-operate retroreflective sensor will give an actively true output when nothing is blocking the light beam. For dark-operate retroreflective sensors, the output of the sensor will be actively true when the light beam is blocked or if the sensor is misaligned.

Why does this matter? Considering that most sensors nowadays are wired back to a programmable controller such as a PLC you would think that either mode, light- or dark-operate, would be fine since you could always reverse the logic if desired in the controller’s program. However, this is just assuming you only want to detect objects. Take for example a material handling application, specifically a conveyor. With a photoelectric sensor installed on a conveyor, we not only want to detect objects but we also want to check for jams. Do you think a light- or dark-operate sensor doesn’t matter still? Well, a jam would be detected if the sensor sees an object for too long of a time, right? Sure, you can do that with either a light-operate or dark-operate photoelectric sensor. It would also detect the same condition if a retroreflective or through-beam sensor were misaligned.

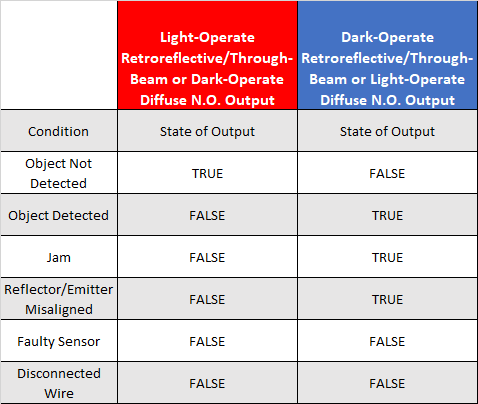

However, what if the sensor fails or a wire becomes disconnected? What would that look like to the operator? Since a jam, faulty sensor, or disconnected/cut wire will all require human intervention, does it really matter if we can distinguish one from the other in the controller? The table below shows the output states for the different types of sensor operations and possible conditions.

As you can see, for a light-operate retroreflective or through-beam sensor or a dark-operate diffuse sensor, we will only get an active true condition if an object is not detected. We get an active-false output state for all other conditions. Based on the length of time the output remains false, we can determine if there is a problem at the sensor that needs to be investigated. If we select a sensor that outputs an active-true output when an object is detected, as with a dark-operate retroreflective or through-beam sensor or light-operate diffuse sensor, it is harder to determine if we have a disconnected wire or faulty sensor. The length of time the output is true could tell us about a jam or misalignment but wouldn’t alert us to a broken connection or faulty sensor.

As mentioned earlier, there are many considerations when choosing the right sensor for your application. The sensor’s operation, the material being sensed, even the surrounding atmosphere can all play a part in this decision. AutomationDirect offers a wide selection of photoelectric sensors. For more information on the options available, follow this link.