AA Absolute Automation And Electrical Services, Inc. is an independent control systems and industrial electrical company based in Covington, Georgia. They provide solutions to both end user and OEM clients in many industries including material handling, chemical processing, food and beverage, metals processing, plastics, recycling and general manufacturing. Services offered range from complete turnkey automation systems to scheduled and emergency service calls relating to electrical wiring, programmable controllers, AC drives, pneumatics, and other control system components.

AAA specializes in PLC and PAC based control systems and provides engineering and design services, controller programming, custom control panel fabrication, system installation, start-up assistance, and documentation for almost any sized project.

Their experience has been gained through numerous projects ranging from simple troubleshooting to complete design and installation of complex plant control systems.

One area that sets AAA apart from their competitors is the level of documentation they deliver with each control system. Documentation packages are designed to quickly give clients information they need to fully understand, operate and troubleshoot the system. Many systems are supplied with remote access capability, allowing AAA to assist with troubleshooting issues from anywhere in the world via the Web.

The Proposal

Recently, a chemical producer approached AAA seeking energy saving suggestions in their manufacturing process. The client stored finished products in forty agitated tanks. Since manual push buttons and across-the-line motor starters controlled the agitators, they ran continuously at full speed, even though most of the products did not require it.

Energy Saving Opportunity

To capitalize on this energy saving opportunity, AAA replaced the existing motor starters with a series of DURApulse drives connected to a DirectLOGIC D2-260 PLC based control system. Now plant operators, using a C-more operator interface screen, easily set each agitator to run the minimum speed and period of time required to maintain a quality product. Agitators can also be set to automatically cycle on and off, based on easily configurable time schedules. The resulting energy savings yielded a very short payback time for this project.

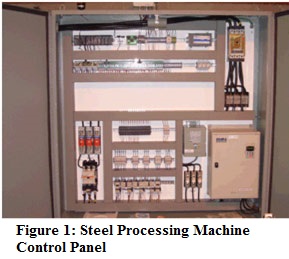

AAA also utilizes the industry’s latest products to upgrade control systems on existing manufacturing machinery. During a recent system upgrade, a forty-year-old pushbutton and relay control system on a steel processing machine was replaced with a modern system consisting of a DirectLOGIC D2-260 PLC, C-more operator interface screen, and Fuji motor starters. ZIPLink pre-wired cables were used to decrease panel fabrication time and reduce costs.

Because the old control system utilized a two-speed reversing motor starter to control the machine’s main motor, constant speed changes caused a great deal of mechanical wear to the machine. When the old system was upgraded, the starter was replaced with a DURApulse drive. (Fig. 1) This upgrade allowed the machine to accelerate smoothly between speeds, thus greatly reducing mechanical wear. The machine now runs at its most efficient speed during every phase of the production cycle.

Because the old control system utilized a two-speed reversing motor starter to control the machine’s main motor, constant speed changes caused a great deal of mechanical wear to the machine. When the old system was upgraded, the starter was replaced with a DURApulse drive. (Fig. 1) This upgrade allowed the machine to accelerate smoothly between speeds, thus greatly reducing mechanical wear. The machine now runs at its most efficient speed during every phase of the production cycle.

AutomationDirect products are also used extensively in control panels built for original equipment manufacturers. Recently AAA chose a DirectLOGIC DL06 PLC, C-more Micro operator interface screen, and a SureServo motion system to accurately cut foam to correct lengths during a laminating operation. The torque control mode of the SureServo drive allows the machine to keep the proper tension in the foam sheets during the cutting process.

AAA Absolute Automation and Electrical Services, Inc. is proud to use AutomationDirect products in their control systems, allowing them to provide great control solutions at reasonable prices.

For more information please visit: www.aaaelectricalservices.com

By Bob Swarner,

AAA Absolute Automation And Electrical Services, Inc.

Originally Published: June 1, 2010