Tapping into data marooned on remotely-installed automation systems is made practical with new cloud-capable wireless devices.

Bill Dehner, technical marketing engineer for AutomationDirect, wrote an article for the November 2020 issue of Flow Control titled Cloud-Enabled Multivariable Measurement. Here’s a summary, click on the link above for the full text.

Industrial sites commonly operate a significant number of systems and equipment as isolated ‘islands of automation’. Remote locations, legacy hardware, and incompatible automation platforms have often made it expensive or unfeasible to tap into the valuable data available from these systems.

Today’s internet of things (IoT) concepts and technologies address these and other issues, leading to the development and deployment of new portal devices. These devices make it easy for users to gather and visualize this remote data, often just a few points of key interest, using cloud-based methods. Without impacting existing operations or developing any custom software, users can deploy these portals to:

- Monitor measurement points

- Transmit them to the cloud

- Log the data

- Provide basic alarming functionality

- Enable mobile visualization

A Wealth of Sources

Field input/output (I/O) signals can come from:

- Individual sensors or instruments

- Hardwired control panels

- Local programmable logic controllers (PLCs) or other dedicated controllers

- Intelligent devices and systems

A portal device is the best solution for connecting to these points with minimal required effort whether they are on existing or new systems, and with zero impact to existing systems.

Smart Portal Solutions

The key features of a smart portal solution include:

- Small and easily installed form factor

- Built for industrial environments

- Simple hardwired connectivity for common discrete and analog signals

- Support for the common Modbus RTU industrial communications protocol

- Wi-Fi networking to site and cloud services

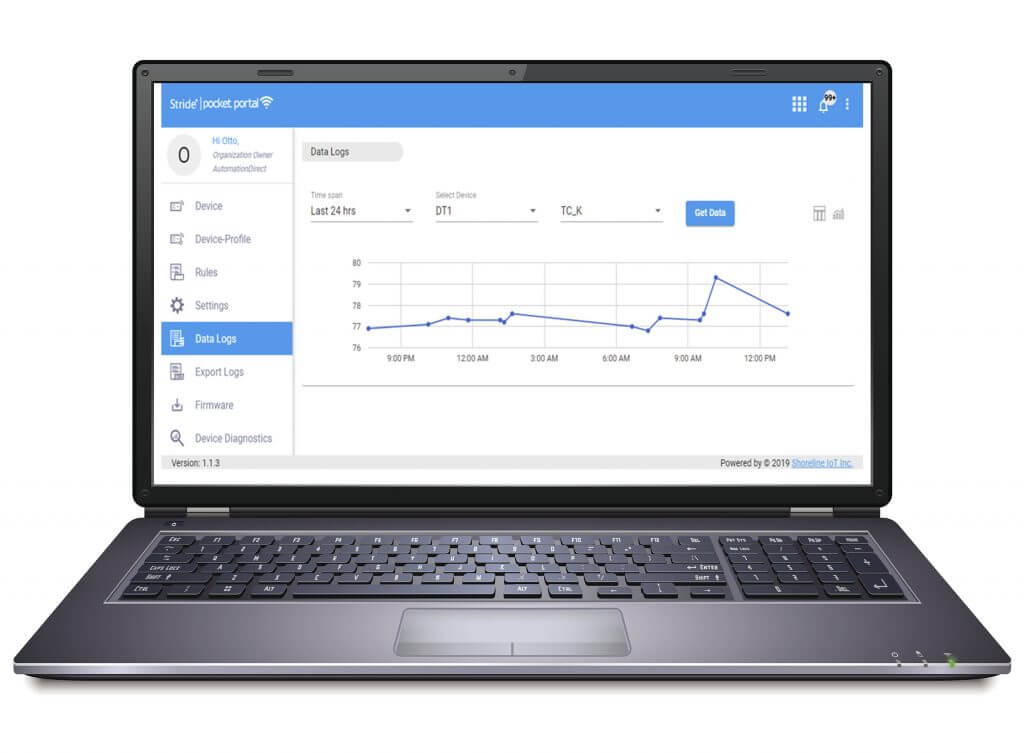

- Plug-and-play cloud-based data logging and exporting, with mobile notification and visualization

While the installation considerations are important, a comprehensive and low-cost cloud service is what really liberates users from the effort, expense, and complexity of creating and maintaining their own custom solution.

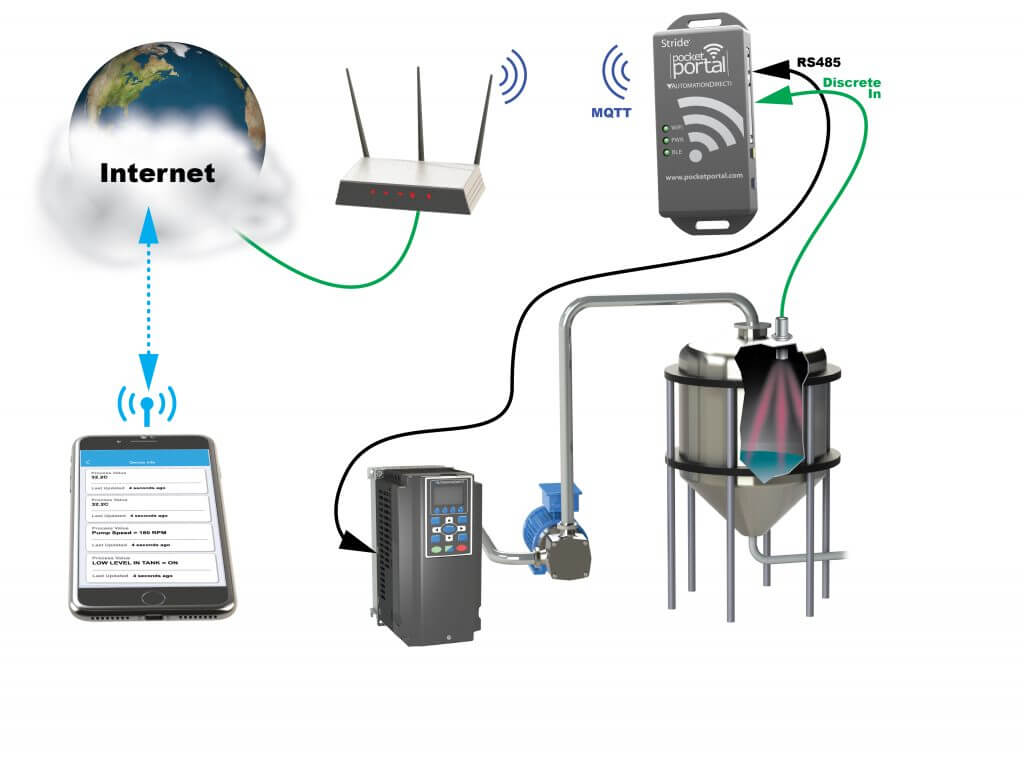

Setup and deployment are facilitated when smart portals use a wireless Bluetooth connection so the user’s mobile device can provision and configure the device locally. The user defines the I/O connections, establishes the Wi-Fi network information, and marries the device and signals to the cloud service. Portals most often use the industry-standard MQTT protocol for secure data messaging, and a complete portal/cloud solution will coordinate these detailed connections so users don’t need to manage them.

End users can gather a multitude of smart portals under one cloud system to provide an overview of their operation. Original equipment manufacturers (OEMs), systems integrators (SIs), and service companies can take advantage of multi-tenancy options for connecting smart portals at multiple clients, while providing the necessary customer isolation.

Abundant Applications

There are countless industries and applications which can take advantage of smart portals to enable remote monitoring. For instance, many systems involve pumps and the associated fluid flows, levels, and pressures.

An end-to-end IoT solution with secure data collection, visualization, and real-time alerts provides users with the tools to monitor and manage these and other types of remotely installed systems.

For a common tank pumping system, a lightweight IoT solution enables users to quickly benefit from creating a tank level audit trail, measuring power consumption, detecting leaks, and avoiding overflow or dry-run conditions. These features reduce the amount of time workers need to visit remote or hazardous areas.

IoT Anywhere

Installing one or more smart portals in conjunction with a cloud-based IoT solution is the best way for users to monitor signals in an industrial setting, without the difficulty and expense of using traditional platforms or creating custom designs.