AutomationDirect washdown-rated VFDs help users add control functionality and realize cost savings even in challenging locations.

Kevin McClelion, product engineer for AutomationDirect, wrote an article for the May 2022 issue of Processing titled Reducing complexity and cost with NEMA 4X VFDs. Here’s a summary, click on the link above for the full text.

VFDs are essential for controlling electric motors speeds, providing useful advantages such as diagnostics, power monitoring, and energy savings. But they have typically required installation in electrical cabinets or rooms with specialized environmental controls. This is a problem for tight spaces, washdown areas, and outdoor locations.

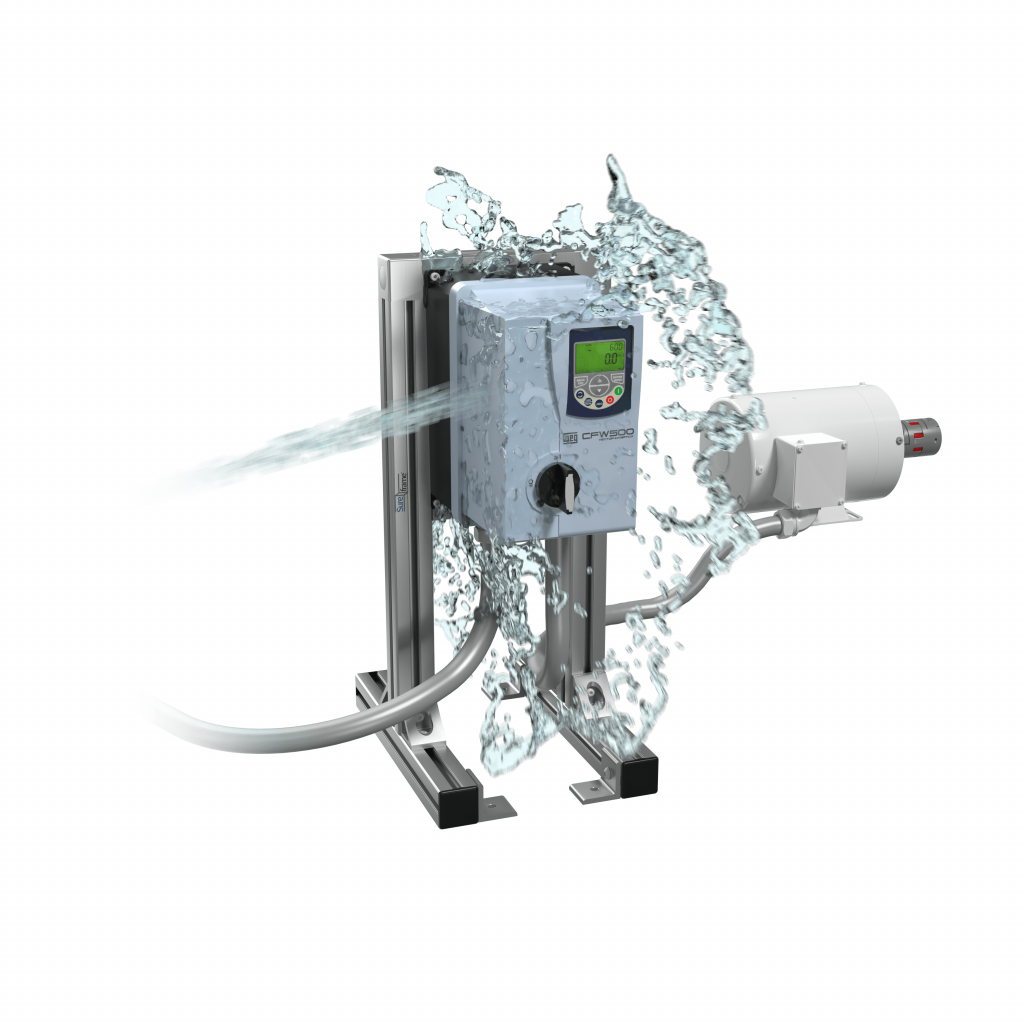

These issues are solved by newer AutomationDirect NEMA 4X VFD solutions which are self-contained, compact, and washdown-rated.

NEMA 4X VFD benefits

Traditional VFDs need to be installed in clean and dry environment, and require long cable runs from this location to where the motor is located. If pushbuttons and lights are required at the motor, then more cables must be run. Long motor leads can necessitate expensive shielded VFD cable and line reactors.

Washdown-rated VFDs (NEMA 4X or IP66) can be installed right near the motor. While they are frequently used in washdown applications for food & beverage and life sciences, they can be used in many kinds of application to save on total equipment and installation costs.

NEMA 4X VFDs are rated for operation at up to 122 DegF without any additional derating. Modular external cooling fans are inexpensive and easily replaced. These VFDs also include integrated options for lockable local motor disconnection.

Designers can use the onboard keypad for start/stop/setpoint/monitoring functions, or they can control the VFD from a master PLC via an Ethernet connection. These VFDs also have a variety of I/O options, so they can control and monitor local devices, without requiring long wiring homeruns to a master PLC. In fact, the VFD embedded PLC can execute logic and PID loop functionality locally, unloading supervisory systems.

While washdown-rated VFDs are typically 70% higher in cost than the equivalent IP20 version, their advantages quickly offset the increased expense by lowering the total project cost.