AutomationDirect’s ProductivityOpen Arduino-compatible automation controller enabled this company to deliver reliable HVAC controls enhanced with modern computing capabilities.

The hands-on attitude of Frank Bicknell led him to start Bicknell Heating & Cooling in the Cincinnati area to support commercial and industrial clients with all types of HVAC needs.

In an April 2022 InTech article bylined by Frank, titled Open PLCs Enhance Building Automation, he describes how his company is using modern industrialized Arduino-compatible microcontrollers to provide open and capable automation for many types of HVAC equipment.

So Many Microcontrollers

PLCs and other more dedicated microcontrollers are often used to automate equipment. They all work well but lack the openness of consumer- and hobbyist-grade general-purpose controllers. However, the latter are simply not tough enough for industrial applications. Frank investigated many options, as well as associated methods for providing HMI functionality, but had trouble finding a suitable solution.

Discovering a Tough Open Controller

This changed when he discovered that AutomationDirect offers the ProductivityOpen Arduino-compatible CPU and associated modules, which also work with the company’s extensive line of proven PLC I/O. With the ProductivityOpen, users can create control solutions using modern programming languages and methods like C++ and “sketches,” they can connect with typical industrial signals, and they can even take advantage of Arduino “shield” modules.

Open Building Automation

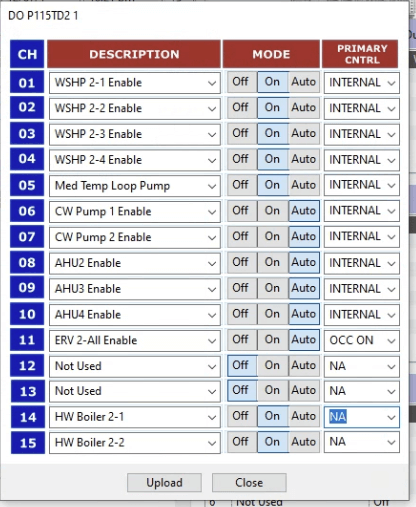

Most commercially-available HVAC control platforms are proprietary and expensive, and somewhat over specialized. PLCs can do the job in many cases, but the ProductivityOpen provided the best of both worlds at an economical price point. The team’s first project was to re-automate the HVAC system of a nearby school. This entailed monitoring temperature, humidity, pressure, airflow, and more, while controlling valves, and VFDs for pumps and fans. AutomationDirect supplied most of these devices, speeding up design, procurement, and fabrication.

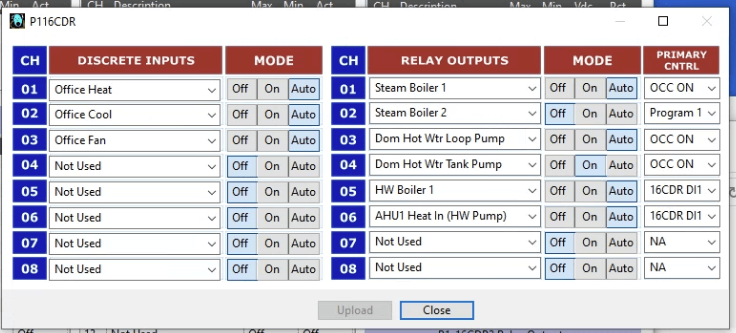

The project automated 15 air handlers, one chiller, two steam boilers, four hot water boilers, and several water-supply pumps.

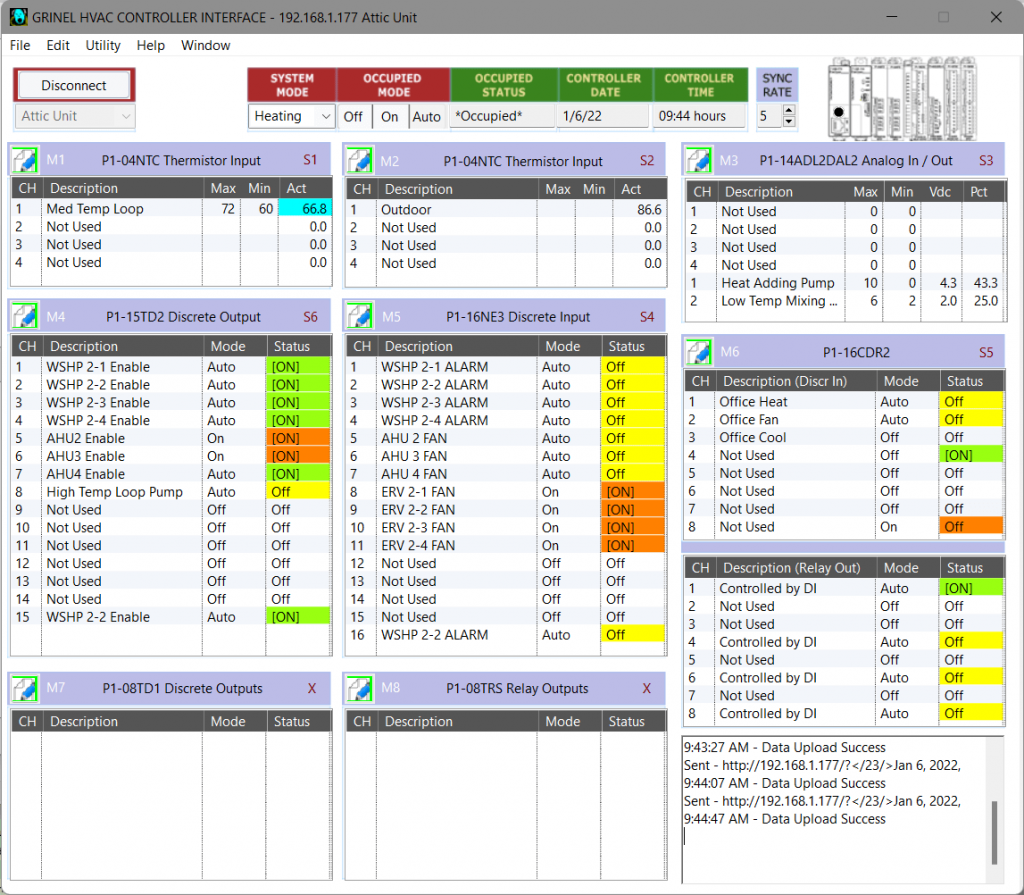

All the control logic is executed within ProductivityOpen controllers, which are programmed to run temperature control algorithms, including weather reset functionality so the system can efficiently adapt to the exterior climate. A PC running Visual-Basic-like Xojo provides a supervisory front end so operators can visualize system functionality and adjust settings.

The system was commissioned rapidly during off hours, and it has performed admirably ever since.

The control system has functioned reliably; there is plenty of capacity to expand; and the school personnel have found the system easy to use. We are now using the system for on-site visualization and control. In the future, we can add more controlled systems and even expand operating capabilities.

Future additions may include remote access, and the open nature of ProductivityOpen means there are many options for enhancements. Bicknell has found the ProductivityOpen to be capable and an excellent value, and plan to use this platform for other commercial and industrial applications.

Check out the AutomationDirect.com website today to explore products that can help your company control its own automation destiny.

All figures courtesy of Bicknell Heating & Cooling