Building the Electrical Control Panel

There are many things to consider when building an automation control system. Some control systems are extremely simple, like a pump control system that consists of a pump, level controller, and a contactor, or they can be complicated and control a full production line with a series of sub control systems. No matter the complexity, control systems consist of sensitive electrical instrumentation, connections and devices that need protection from environmental factors.

Most often, an electrical enclosure or panel is used to shield the control devices from natural elements like rain, snow, heat or cold, as well as chemical, water or corrosive liquids. Enclosures also ensure the system is safe from accidental contact with personnel, and from being affected by hazardous conditions in the area where they are used.

Enclosures come in many sizes, shapes, materials, and specifications that allow a system designer to select the safest and most cost-efficient enclosure for their specific application. Once the enclosure is selected, a panel builder installs the components, devices, and wiring according to the specifications provided by an engineer and/or current electrical code(s) (NFPA 79 for instance).

Enclosures come in many sizes, shapes, materials, and specifications that allow a system designer to select the safest and most cost-efficient enclosure for their specific application. Once the enclosure is selected, a panel builder installs the components, devices, and wiring according to the specifications provided by an engineer and/or current electrical code(s) (NFPA 79 for instance).

A Panel Builder’s Component Checklist

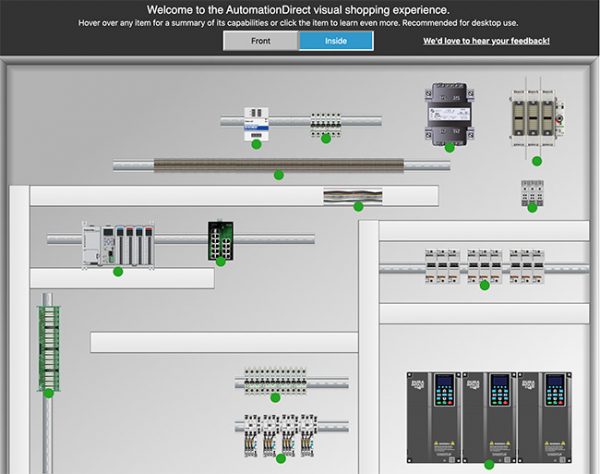

To give an idea of the many components, equipment, accessories, and devices available to complete an automation control system and that may require installation in an enclosure, we are providing a list of possibilities as a reference. This list is a starting point and can grow depending on your specific project.

Also, the Panel featured in the photo is an interactive online cabinet designed to visually aid in the shopping/selection process and has links to more information for each of the panel components shown. We’d love it if you gave it a look and provided feedback. There is a link on top of the page for a short survey.

To experience Parts Explorer for yourself please click here!

Panel Builder / Designer Checklist:

- Enclosures: Safely enclose components/devices. Available in a wide range of materials, mounts, dimensions, styles, and NEMA ratings (see more about NEMA ratings on Page 4).

- Thermal Management: Provides ideal conditions inside enclosures to prevent component overheating and/or condensation.

- Wiring/Accessories: These include wires, terminal blocks, connectors, glands, conduit, wire ducts, and cable ties.

- Electrical Power Devices: Such as transformers, power monitors, panel meters, power distribution blocks, power supplies, surge protectors, and power line filters.

- Cables: Facilitate communication and control signals (i.e., cables for encoders, sensors, monitors, drives, solenoid valves, motion control, PLCs, HMI, PCs and more).

- Circuit Protection: Protect electrical components and/or devices via ON/OFF controllers, disconnects, circuit breakers and fuses.

- Control and I/O Devices: Provide automation functions as needed for an application. Examples include PLCs, Field I/O, and PC-based Control.

- Process Control and Measurement: Controllers or sensors that continuously monitor changing variable data and may use it to control devices in a system. For example, a temperature controller.

- Motor Control: Provide electrical control for motors via a soft starter, variable frequency drive, motor starter, motor disconnects, or contactors.

- Communication Devices: Ethernet switches, gateways, VPN routers, and serial communication devices that provide communication between components and devices.

- Drives: Control motor speed, torque and direction.

- Operator Displays: Includes HMIs and industrial monitors used to display system conditions and can provide functions like turning a device ON or OFF.

- Motion Control Devices: Control systems with accurate position/velocity/torque capabilities operating in open or closed loop modes. Examples include gearboxes, servo and stepper systems.

- Pilot Devices: Provide ON/OFF controls, system selectable options, status indication, and more. These include switches, pushbuttons, indicators, stack lights and audible signaling.

- Relays and Timers: Provide simple control or power conversion for many automation systems.

- Safety Devices: Ensure personnel/equipment safety to protect lives and equipment damage. Some examples are Emergency Stop pushbuttons, enclosures with locking mechanisms or with Lockout/Tagout hardware

Learn more about designing an automation control system from the “Automation Control System Specification, Design and Installation” article in this publication on Page 6.

Read more articles related to panel building and enclosures.

*Originally published: Nov 7, 2018