A trailer-mounted water treatment process controlled by a Productivity2000 PLC has recently been developed at the University of Idaho. Professor Greg Möller, in the College of Agriculture and Life Sciences, along with engineers from the College of Engineering have teamed up to build the platform, and to further research the economical removal of phosphorus from various wastewater sources.

The Project

The engineering effort is part of a capstone project involving a number of engineering students and a French industrial water engineering intern from Suez Environment, led by Martin Baker, a mechanical engineer on staff at UI. Gene Staggs is a recent graduate from the engineering school, and is the Automation and Control lead on the project. Gene contacted AutomationDirect in early June, asking about PLC options to control the project. In addition to the technical criteria, he also explained the accelerated timeline for completion of the project. AutomationDirect technical staff reviewed the capabilities of the Productivity2000, and assured him that his entire bill of materials could ship the day he placed the order.

While the primary function of the mobile platform is to go “on-site” for up to a week at various locations (paper mills, lagoons, and larger waste water treatment plants) to process effluent, remove phosphorus and collect samples, the platform is also a STEM Educational vehicle. The development team has already coordinated tours for elementary through high school teachers, and they have plans to take the platform to various professional conferences as well.

The Treatment Process

The treatment process is accomplished via a pair of “plug-flow” reactors in series, each followed by a corresponding self-cleaning sand filter. The reactors are 45 feet long, constructed from 6” diameter PVC pipe (the green tubing in the pictures). The first reactor introduces low doses of biochar, a less expensive, yet similar material to the activated carbon used for many filtering applications. After moving through the first reactor, samples are taken and the effluent moves into the first sand filter. Samples are taken again, and the effluent moves into the second reactor where precise quantities of ozone are injected. After a third sample is collected, the effluent moves through the second sand filter, a final sample is collected, and processing is complete.

The entire process is known as “catalytic oxidation”; it allows for destructive removal of most organic contaminants (they are mineralized to carbonates) and it sterilizes the water, killing all microbial life including prions, viruses, and bacterial spores. Mineralized nutrient phosphorus and nitrogen are bound to the biochar and recovered from the water. The nutrient-laden biochar can be recovered and pelletized for use as fertilizer and as a soil amendment in agriculture.

The mobile platform processes about 15 gallons per minute, but because it is based on a commercially proven process, it is scalable to tens of millions gallons per day.

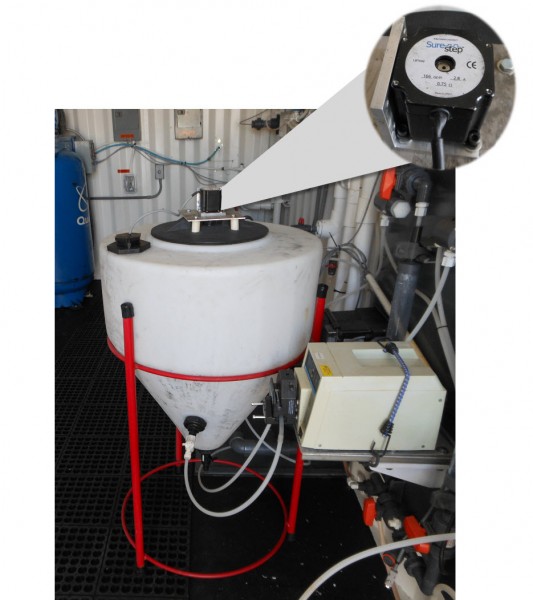

The Productivity2000 PLC controls all aspects of the filtration process, from opening and closing valves, to metering the biochar, ozone, and the sampling operations. A pair of AutomationDirect SureStep™ stepping systems are also used for preprocessing of the biochar. Commercially available biochar is available in three forms: powdered, slurry and suspension. The engineers developed a creative approach to manipulate and meter the biochar, regardless of type. Three sets of custom 3D printed parts were designed to fit on the shafts of the stepper motors. A simple auger processes the powdered form, an auger and a linear actuator are used for the slurry form, and a pair of mixer paddles and peristaltic pump are used for the suspension form of the biochar. The Stepper systems are controlled using a high-speed output card (P2-HSO) in the Productivity2000.

Additionally, the Productivity2000 is running eight separate PID loops (with auto-tuning); it also communicates with a C-more touch panel HMI for operator control. “It is a great system to work with – some of the best features were the custom tag names, PID features and QR codes” said Gene, just after completing the three-week build. Gene also reports that the import/export of the tag database was a huge time saver, and the team was even able to use the spreadsheet style tag data to help document other parts of the project. He pointed out other benefits as well, “Because this is also a research vessel, the data logging and network capabilities are invaluable.”

The mobile platform gives the team a great vehicle to further their research and to show wastewater treatment operators the benefits of the new technology. While it is still in the fairly early stages of development, the results are very promising. Existing studies conclude that reactive filtration is one-third to one-half the capital, maintenance and operation costs of other approaches, AND the process will produce useful fertilizer, clean reusable water, and even carbon trading credits.

Interested parties should contact the University of Idaho (ott@uidaho.edu) or professor Greg Möller (gmoller@uidaho.edu)

Originally Posted: Aug. 5, 2015