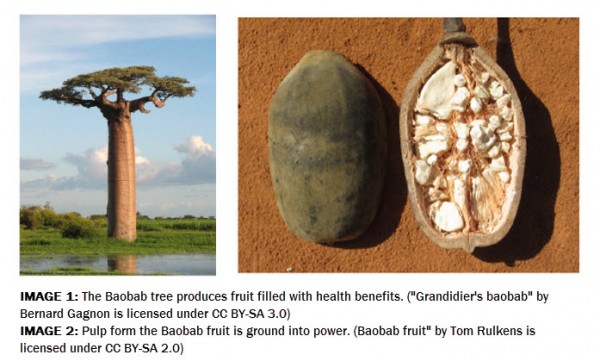

Students at Penn State have been working on a Baobab pulp processor in conjunction with the residents of villages in Benin, Malawi, South Africa, and Madagascar. Native to Africa, “Baobab” is the common name for the Adansonia tree and the fruit that it bears. There has been quite a bit of hype surrounding the health benefits of Baobab in recent years, and many pundits have speculated that exports of the powdered form of the fruit could net over a billion dollars per year, provided the producing nations can ramp up production and exportation operations. (Image 1)

The Baobab tree is known as the tree of life, and it produces a fruit about the size of a large coconut, with a velvety shell. The pulp inside the pods is very high in vitamin C, dietary fiber (up to 50% by weight), and thiamin. (Image 2) The powdered pulp is added to shakes and used as a sweetener for other fruit drinks, and can also be used as a thickener for jams and other foods.

Processing of the pulp in Africa has historically been done by hand, with village women manually crushing the pulp in a large mortar and pestle operation. It is an arduous task, very slow and not very clean, but it is still the most common way to produce the powder.

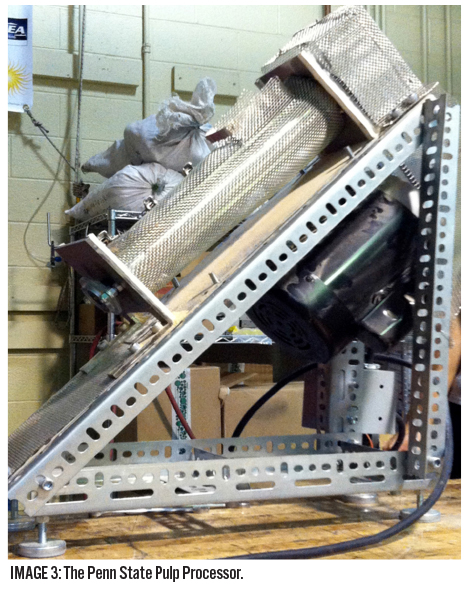

The engineering students at Penn State set out to help their contacts in Africa with a mechanical means to crush the pulp into powder and to remove the seeds. The students are also working on a secondary machine to help process/press the seeds into Baobab seed oil, for which there is also a high demand.

The Penn State Pulp Processor uses an AutomationDirect IronHorse® AC motor attached via chain to drive a cylindrical stainless steel “heart” which has grooves machined in its surface. It is surrounded by a mesh that helps grind the pulp into a very fine powder and separates the seeds. (Image 3) “One of the neat things about the IronHorse motor is that, in addition to being quite rugged, it can be wired to either the 110V used here in the United States or the 220V used in Africa,” reports Andrew “Mike” Erdman, the Director of Engineering Leadership Development program and an Instructor in the Engineering Science and Mechanics department at Penn State.

Mike reports that the design process has taken several years, and more than a few trips to Africa to refine, “Initial designs were huge, bulky, weighty, and did not work well at all. We started about 5 years ago, and took a machine to Benin, where it was used briefly. We watched the machine in operation, got feedback from the operators, and went to work on improvements. Unfortunately, one of the issues is that we have such limited supply of Baobab pulp here [in the USA] that we need feedback from those users in Africa who need to run the machines for extended periods. We are lucky to be able to have enough pulp [state-side] to run it for a minute or two.”

Excluding the earlier prototypes which were not as functional, the students have produced about fourteen machines which are now operating in various African countries. Mike estimates that the machines can process a kilo of powder in under three minutes. (Image 4) That’s less than 5-10% of the time required by the manual process, and because the mechanical processor only contacts the pulp with stainless steel components the process is much cleaner, and the resulting powder is much more pure than is produced by the manual method.

While Mike admits that the machine is not inexpensive (especially by African standards), the roughly $1,400 USD cost is largely due to the requirement for the many stainless steel components. Even with this expense, the increased production volume and purity helps the villagers enormously. (Image 5) Now they can focus on the other less strenuous, but still labor intensive, parts of the operation including: the gathering of the fruit, opening the fruit to remove the pulp, bagging the refined powder, and shipping to local or export markets.

Next Steps

The Penn State student team is also working on a design for a Baobab seed oil press which should be a valuable adjunct to the pulp/powder machine. Baobab seed oil is used in cosmetics, lubrication and cooking, and is quite valuable both for local use and as an export for the local villages. (Image 6)

This machine is based on an AutomationDirect IronHorse AC motor, coupled to a 60:1 IronHorse worm-type gearbox. Early designs used a 1/2 HP motor, but even with the 60:1 reduction in speed, and a 1:60 increase in torque, the seeds are so hard that the motor stalled!

Early testing with an 8-ton hydraulic ram had already proven that the seeds could be squeezed of their oil, and the students are now reworking the machine to use a motor with double or even triple the power of the original motor. This combination should generate the tremendous force required to extract the valuable oil from the seeds of the Baobab.

By Chip McDaniel, AutomationDirect

Originally Published: Sept. 3, 2015