The right mix of automation elements is crucial for creating a consistent process yielding high-quality donuts and baked goods.

By Roger Dyer, Mel-O-Cream Donuts International

Mel-O-Cream, a commercial bakery in Springfield, IL, has been baking and perfecting donuts since 1932. From measuring precise ingredient amounts and maintaining a consistent mixing process, to ensuring uniform dough shaping and controlling product flow, technology plays an important role in producing premium baked goods. The company has found automation essential to compensate for environmental factors, achieve consistent baking times, and maintain ingredient and lot traceability. Over the years, Mel-O-Cream has invested in automation to enhance both product consistency and process efficiency (Figure 1).

With operations spanning more than 90 years, Mel-O-Cream relies on a variety of equipment with varied automation features and controls that are as diverse as the baked goods and frozen dough that they produce. Specialized baking equipment and machines are often delivered with on-board controls from various suppliers. Despite best efforts to standardize controls throughout the facility, they found themselves with several PLCs from one major automation supplier, most HMIs from a second supplier, and their print management software for applying labeling and barcodes from a third, not to mention the various sensors and controls on specialty equipment.

Although integrating machines and parts from multiple vendors can sometimes create challenges, it is also an opportunity to approach old problems in new ways. Like many companies of this size, Mel-O-Cream has far more production personnel compared to technical staff. As the sole control engineer on staff, Roger Dyer relishes each time a unique challenge comes along. With a major automation investment underway at Mel-O-Cream, it was the perfect time to seek out and investigate new ways to monitor and visualize crucial elements of the baking process.

Perfecting the Proofing Process

The baking process is sensitive to environmental factors—even slight variations in temperature and humidity can significantly impact the final product. Traditional donut recipes made with yeasted dough require time to proof, or rise, before they are transferred to the fryer for cooking. To ensure the dough rises uniformly from batch to batch, bakeries commonly utilize proofing boxes. A proofing box is a heated enclosure designed to hold multiple trays of dough. Proofing boxes are equipped with sensors that continuously monitor humidity and temperature levels. If conditions deviate from the ideal range, the settings can be adjusted to maintain optimal proofing conditions for yeast fermentation.

Because the conditions inside the proofing box can affect rise—and overall process—time, the production team was eager to use automation to achieve better consistency. In addition, it was critical to be notified if conditions inside the proofing box begin to drift, so corrective action can be taken. With this in mind, the production managers and bakery leadership requested greater visibility to conditions inside the proofing box and they turned to Roger for solutions.

Stacking up Solutions

Traditionally, stack lights have been used in industrial settings—including commercial bakeries—as the default way to provide visual status indications at a glance. Positioned so they could be seen throughout the bakery, a three-color stack light could be used to indicate acceptable, warning, and alarm conditions for a specific sensor. Therefore, bakery management thought a stack light solution would be the answer.

However, this particular proof box had two zones with temperature and humidity sensors in each zone. A stack light solution would require four individual towers. Operators would need to remember not only what each tower represented, but also the significance of the three colors in each tower.

After getting input from the production staff, Roger discovered that both operators and maintenance could work more efficiently with additional information—specifically the actual temperature and humidity values at a given time, rather than just a range. Given the cost and complexity of the stack light option, it was decided that a different approach would better serve the needs of monitoring the proofing box.

Raising the Bar…and Saving the Dough

It was clear that the proofing box would benefit from the additional detail available via a human-machine interface (HMI) screen. However, a small local display would provide neither the visibility nor the convenience desired. To better address the application requirements, Roger proposed a headless HMI solution. A headless HMI provides the same functionality as traditional HMIs with integrated displays, but it operates without a local display or interface. Instead, the headless HMI can drive an external monitor of any size, and communicate securely with other remote PCs or mobile devices, allowing for greater flexibility in placement without any display size restrictions.

With more than a decade of experience configuring industrial HMIs, Roger immediately turned to AutomationDirect. The C-more EA9 Headless HMI (Figure 2) proved to be the ideal choice, easily integrating with the existing proofing box controls from another automation manufacturer. The EA9 features Ethernet, serial, and USB ports, making it compatible with many control systems. It also offers remote access, and data logging capability with an SD card slot for additional memory, which is helpful for capturing process data. In this case, the EA9 visual output was connected to a 65” television via an HDMI cable to provide clear visibility even from a great distance.

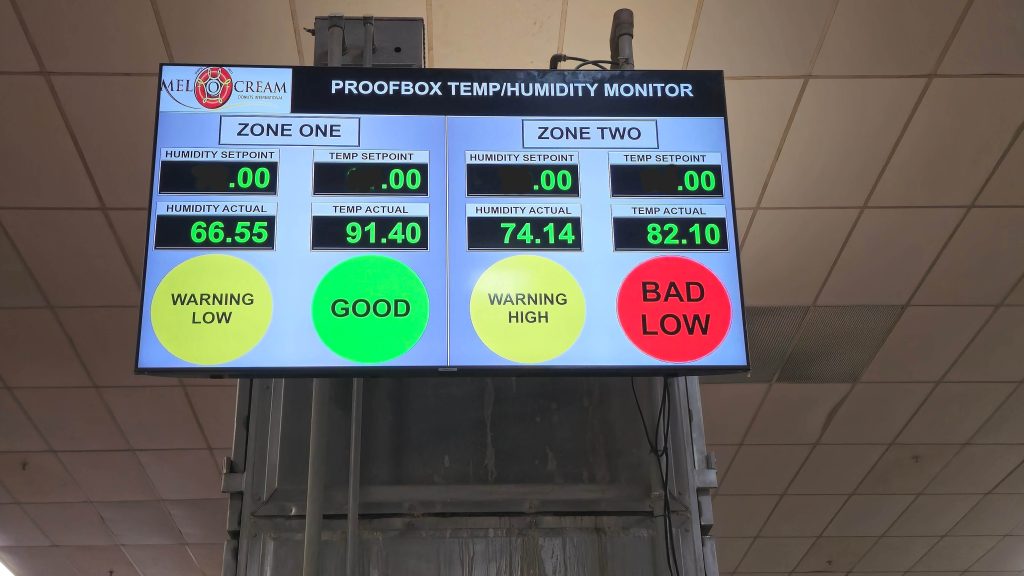

The large, color display is intuitive and visible throughout the bakery floor (Figure 3). Real-time operation data is obtained from the sensors via an Ethernet connection with the existing PLC, so the HMI can display information including each temperature and humidity setpoint as well as actual values. A color-coded graphic status is also visible so production staff can quickly determine when to investigate and take action.

Because the headless HMI is located securely in a control panel, and the monitor is mounted up high, they are both effectively protected from washdown activities. Not only does this make routine sanitation easier, but it also results in equipment and installation cost savings since watertight displays and fittings are not required.

With the combination of the headless HMI and the large color display, production staff is able to easily monitor the proofing box. When a yellow or red warning indication appears on the monitor, operators quickly check the proofing box settings or, if necessary, call maintenance. Since implementing the headless HMI solution, the bakery has realized significant reductions in both product loss and defects, because any materializing issues are quickly discovered and resolved.

Timely Answers and Streamlined Procurement

When integrating equipment and controls from multiple vendors, it’s not uncommon for issues to arise. Coordinating between multiple companies can sometimes lead to delays in identifying components or gathering information. However, the support provided by AutomationDirect for this project was phenomenal with all questions quickly and adequately addressed by their support staff.

In addition, the AutomationDirect website helped to make sure the project could be completed in a timely manner. With transparent stocking levels and price visibility, there was no time lost waiting for quotes on products with undesirable lead times.

The Icing on Top

As Mel-O-Cream continues to incorporate automation into their operations, they are doing so thoughtfully to protect existing capital investments. By partnering with suppliers committed to providing not only quality products but also exceptional support and integration assistance, they have effectively mitigated risks while boosting productivity. Leveraging new approaches like the headless HMI solution has increased efficiency, giving them proof that their bakery can meet rising consumer demands and expand production capabilities, ensuring their delicious donuts remain unmatched for years to come.

All figures courtesy of Mel-O-Cream Donuts International

Author Bio

Roger Dyer is a Controls Engineer at Mel-O-Cream Donuts International. With nearly 30 years of experience in automation and controls, he tackles diverse projects—from basic machines to complex robotics—driven by a passion for problem-solving and innovation. With the Ohm’s Law wheel tattooed on his arm as a testament to his dedication, Roger remains committed to the ultimate pursuit of excellence in his field.