Students Sergio Acevedo and Randle Johnson are two of the first students to complete their degrees in Mechatronics Engineering at Southern Polytechnic State University in Marietta, GA. The Mechatronics program at SPSU is a recent four-year degree offering, begun in 2007, which combines topics from Mechanical Engineering, Electrical Engineering and Computer Science to prepare graduates to “work effectively in all aspects of robotics, automated manufacturing, and the design of mechanical devices with imbedded intelligence.

”  The culmination of the degree program is the capstone project, which includes the design, fabrication, testing and presentation of a machine or mechanical system. Sergio and Randle decided to produce their own pad printing machine.

The culmination of the degree program is the capstone project, which includes the design, fabrication, testing and presentation of a machine or mechanical system. Sergio and Randle decided to produce their own pad printing machine.

Pad Printing

Pad printing is an indirect offset printing process used typically for printing on irregularly shaped objects with uneven, curved or recessed surfaces such as golf balls, test tubes, toys, and many other items. It involves the use of a (typically) silicone pad to transfer an image from a printing plate onto a substrate. The unique properties of the silicone pad enable it to pick up an image from a flat plane and transfer it to a variety of surfaces, including flat, cylindrical, spherical, compound angles, textures, concave surfaces, convex surfaces. The image to be printed is often distorted on the printing plate in such a way as to appear correctly on the printed item.

Sergio and Randle decided on the Pad Printing machine in part because it features a good cross section of the various Mechatronics disciplines. The interdisciplinary design elements include: the mechanical structure, the materials, an actuation system, the controls and PLC programming, various electrical components, and finally the automation of the printing process. The students defined the following as their criteria for success:

a.) build a structure to support 65 pounds of force attributed to weight and actuators

b.) complete one print cycle in 10 seconds or faster

c.) a manual mode that completes one actuation cycle

d.) an automatic mode for continuous actuation performance

e.) the capability to print a surface with dimensions up to 10.75″ X 6″ X 2.75″.

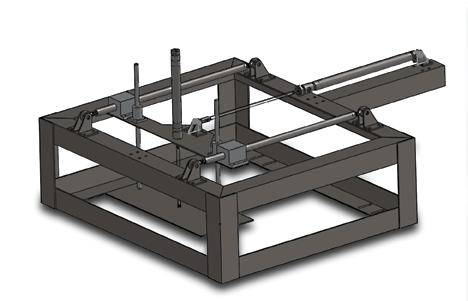

The Frame

Detailed structural analysis helped the students minimize material usage and cost in terms of the structural frame. A 3D model of the machine was created and optimized in Solidworks®, and the students were able to cut the exact shapes and lengths of the various metal elements using the school’s extensive shop tools, including a CNC plasma cutter.

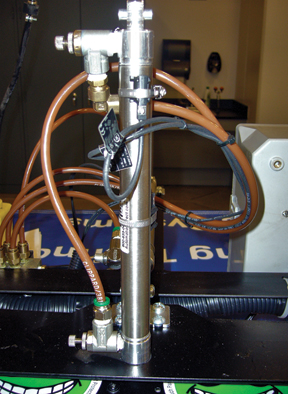

NITRA™ Pneumatics

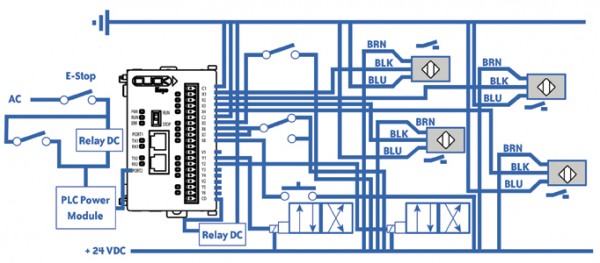

After performing various calculations for load ratios and bore sizes, Sergio and Randle selected a pair of Nitra™ pneumatic cylinders from AutomationDirect to power their two axes of motion: a ¾” bore, double acting rod cylinder with a 10″ stroke for the horizontal axis, and a ¾” double acting rod cylinder with a 6″ stroke for the vertical axis. Four NITRA position sensors are also used to determine when each cylinder is extended or retracted.

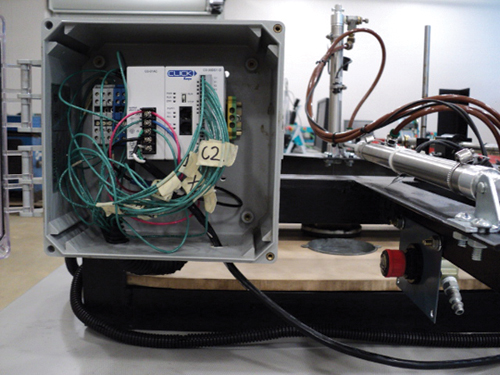

PLC Controller

The students turned once again to AutomationDirect for a cost-effective controller, and selected a CLICK PLC with the C0-00DD2-D CPU to automate their machine. The available I/O included was more than adequate to handle the various pushbutton, switch and position sensor inputs, as well as the outputs that control the pneumatic cylinders. “For $69, it’s hard to imagine a lower cost controller for a machine like our pad printer, and the free software was a breeze to learn with our tight production schedule,” reports Randle.

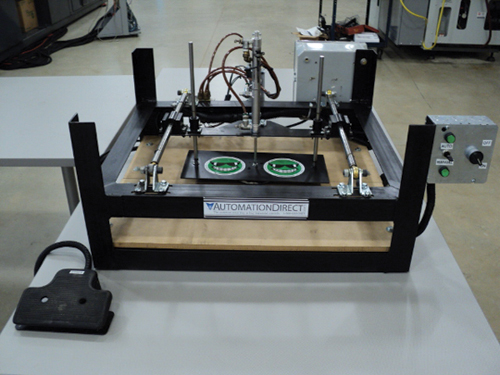

Construction & Review

After assembling the components, wiring the electrical, programming the PLC, testing and subsequent refinement, Sergio and Randle presented their project for review by the SPSU Mechatronics faculty, their fellow students, and several invited guests. Everyone was impressed to see the machine printing Smiley logos on anything placed in the machine’s target printing area.

The machine also achieved all of the project’s stated goals, but Randle and Sergio were quick to point out areas for possible improvement. An application mechanism for ink, touch screen controls (perhaps C-more Micro), automatic part feeding, and additional safety features top their list. Many of these are indeed features or options for the various commercially available machines. “We have a new-found appreciation for the existing Pad Printing machines that are on the market,” admits Sergio. “Building your own version of any complex machine is the only way to fully understand the intricacies of the mechanical and electrical engineering design, and the programming requirements. But hey, that’s what our Mechatronics degrees are all about!” It sounds like mission accomplished at the new SPSU Mechatronics Department!

Provided by Chip McDaniel

AutomationDirect

Disclaimer: AutomationDirect does not guarantee the products described in this article are suitable for your particular application, nor do we assume any responsibility for your product/system design, installation, or operation.

Originally Posted: Sept 1, 2011