Networked electro-pneumatic solenoid banks can be distributed on machines for better control and more efficient installations.

Kevin Kakascik, Technical Marketing Engineer with AutomationDirect, wrote an article for the June 2021 issue of Fluid Power World titled Distributed Electro-Pneumatics Maximize Machine Automation Options. It examines how intelligent solenoid manifolds save space, minimize installation effort, and provide high-performance machine automation options.

Extending the Reach

PLC systems have long used remote I/O devices to extend control to the far reaches of a machine, while minimizing the amount of signal wiring. Original devices were basic I/O blocks connected with simple serial networks, while later iterations became modular and used more powerful fieldbuses. These distributed devices gave designers more flexibility to mix-and-match configurations to best fit their applications.

Distributed Electro-Pneumatics

Pneumatics go hand-in-hand with industrial control systems perform actions like lifting, indexing, pressing, and much more. Solenoids are electro-pneumatic devices used to convert control signals into air pressure and flow.

Original solenoids were individual devices, requiring air tubing connections and wiring. One helpful development was consolidating many solenoids into a compact valve bank.

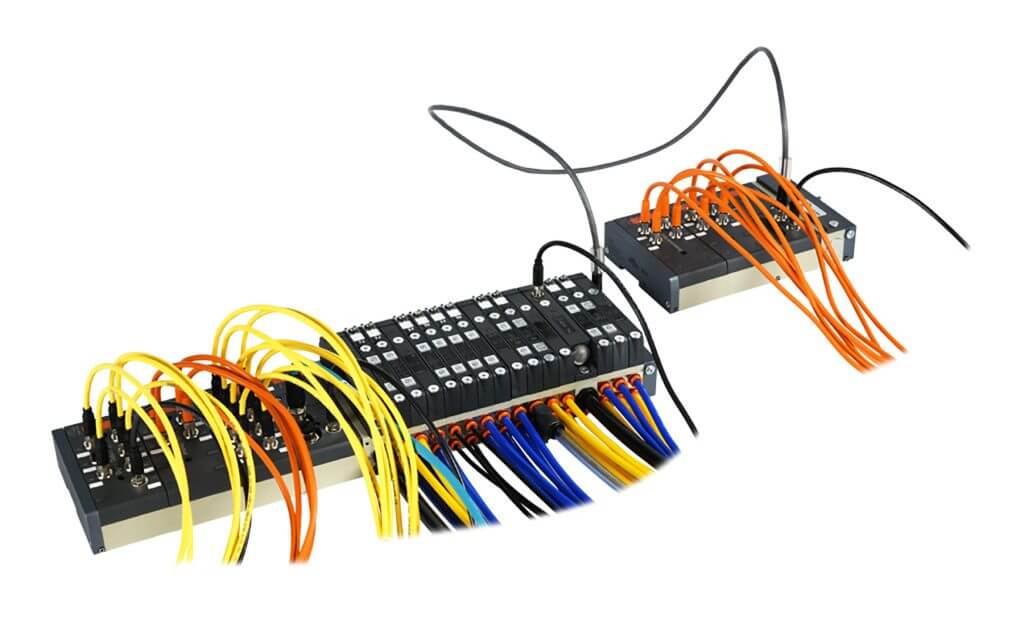

As with I/O systems, there was a growing need for better methods of distributing electro-pneumatics. Modularity was important because there are many variations of solenoids, and each remote ‘drop’ might need just a few or perhaps a great number of solenoids. The flexible answer was a modular pneumatic system, which can include various I/O modules, network communications, and IP65 surface-mount capability. The AutomationDirect PAL family is an example.

Distributing multiple valve manifolds around a machine can also simplify tubing runs and shorten airlines to cylinders and actuators, resulting in simpler integration and faster actuator response. Some manifolds are available with environmental rating options so they can be installed away from electrical panel hazards and right on machines, even in washdown environments.

Many applications, whether they are machines with a high field device count or a conveyor line extending over long distances with a low I/O density, can benefit from smart solenoid manifolds. Modular and intelligent electro-pneumatic installations provide many options for OEMs and system designers to distribute pneumatics and I/O devices in an organized and efficient way throughout an automated machine or system.

These manifolds save space, reduce the need for control enclosures, and minimize the required effort and cost of wiring and plumbing. Users can standardize their designs on vendors, protocols, and products to meet their needs and simplify their efforts—and AutomationDirect has online resources and telephone support specialists available to help users find the best products for their applications.