This is part two of a two-part series on variable frequency drives. In Part One, we discussed how choosing the right variable frequency drive (VFD) can reduce energy consumption, improve realtime control, and lengthen motor life. Here are more expert tips to consider.

Select the Proper Control Mode

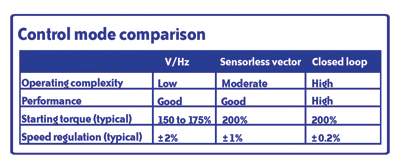

VFD control mode choice greatly depends on the application. The three VFD control modes are volts-per-Hertz (V/Hz), sensorless vector (sometimes called open-loop vector), and closed-loop.

V/Hz-type VFDs use the ratio between voltage and frequency to develop the operating flux to supply operating torque to the motor. Sensorless-vector VFDs have accurate torque control over a wide speed range without having to use encoder feedback. Closed-loop VFDs use encoder feedback to obtain motor speed and slip information.

V/Hz control is adequate for many applications such as fans and pumps. However, for applications that require greater degrees of speed regulation, sensorless vector or closed-loop control types may be necessary. Applications such as paper mills, web printing presses, or material converting require the added speed regulation that closed-loop control provides.

Understand Your Control Profile Requirements

Selecting the proper VFD control profiles is critical and depends greatly on the application. Control profiles to consider include acceleration, deceleration, ramp linearity, torque control, braking, and PID. Most of these parameters are available on nearly every VFD type on the market, but PID may not be offered on very basic models.

These parameters are programmable and can be selected using the operator keypad, or by digital communications. Understanding these parameters (and how they affect integration of the VFD into the process) is imperative; to this end, VFD user manuals typically provide the information required to select and program the right control profiles.

Know Your Communication Options

Many VFDs have one or more built-in digital communication interfaces. Even the most economical models typically include a serial interface such as a Modbus RS-232/RS-485 connection. Ethernet and fieldbus communication are options offered with many VFDs.

A digital communication interface can be used to connect the VFD to other devices that can function as a master device such as a PLC or PC-based controller. The master device can control the VFD with this interface instead of using the discrete and analog I/O. The master can also use this interface to monitor the status of various VFD parameters such as speed, current, and fault status.

An RS-232 connection is somewhat limited as the maximum RS-232 network cable length is 50 feet. Also, the RS-232 interface is one-to-one, allowing connection of one VFD to one controller. An RS-485 network cable can span up to 4,000 feet and allows connection of multiple devices. However, extra adapters may be required to make this type of connection.

An Ethernet interface provides a low-cost, high-performance link between the control system and multiple VFDs. Some VFD Ethernet interfaces are even available with a Web server that allows users to configure and control the VFD from any Web browser. Ethernet protocols such as Modbus TCP/IP and EtherNet/IP take the guesswork out of VFD control over Ethernet and make setup easy for non-IT users.

Don’t Overlook Installation and Operating Requirements

VFDs generate a significant amount of heat. This heat can cause the internal temperature of an enclosure to exceed the VFD’s thermal rating. Enclosure ventilation or cooling may be necessary to keep enclosure temperature within specified limits. Ambient temperature measurements and calculations should also be made to determine the maximum expected temperature.

Operating precautions must also be considered. One should avoid running a standard induction motor at low speed for an extended period of time, as this can cause the motor temperature to exceed its rating due to limited airflow produced by the motor’s fan.

When a standard motor operates at low speed, output load must be decreased. If 100% output torque is desired at low speed, it may be necessary to use an inverter-duty rated motor.

Don’t use a contactor or disconnect switch for run/stop control of the VFD and motor: this reduces VFD life. Cycling the input-power switching device while the VFD is operating should be done only in emergency situations.

Beware of Harmonics

Any non-linear load, which includes anything with rectifiers, generates harmonics — including VFDs. If excessive, harmonics can overheat and damage equipment, transformers, and even power distribution wiring.

Two types of filters can mitigate the harmonics associated with VFDs. Passive harmonic filters include AC line reactors and chokes. Reactors and chokes reduce VFD-related harmonics and line notching, and are recommended for all installations. They also protect the VFD from transient overvoltages, typically caused by utility capacitor switching. Active harmonic filters sample the harmonic current waveform, invert it, and feed the inverted waveform back to the line to counteract harmonics. Some active filters also have dynamic braking circuits that allow motor deceleration to place regenerative current back on the ac supply line.

Output, or load, reactors protect motor and cable insulation from VFD short circuits and insulated gate bipolar transistor (IGBT) reflective wave damage. They also allow the motor to run cooler by smoothing the current waveform. Output line reactors are recommended for operating non-inverter duty motors and for where VFD-to-motor wiring exceeds 75 feet.

Read Part One here: http://library.automationdirect.com/top-10-tips-specifying-vfds-part-one-of-a-two-part-series-issue-20-2011/

For more information, call (800) 633-0405 or visit automationdirect.com.

This article originally printed in the February 2011 issue of MSD magazine.

By Joe Kimbrell,

AutomationDirect

Drives, Motors, and Motion Control

Product Manager

Originally Posted: Sept 1, 2011

1 Comment