An innovator found a way to upcycle bottle caps into extraordinary products, an activity that also helps support local children’s charities. By applying practical AutomationDirect devices and components, he has efficiently scaled up production.

When Nathan Rues started a hobby of collecting bottle caps while in college, little did he know that one day this would grow into a sideline business benefitting children’s charities. It all started after he was inspired to create a mosaic version of Van Gogh’s “Starry Night” using various colors of bottle caps.

Nathan’s article in Design News August 2021 titled Want a Cool Product? Kids Go Wild with Bottle Caps describes how he increased his automation skills using AutomationDirect devices and components to create machinery, and to overcome the limitations of sorting and processing the bottle caps manually.

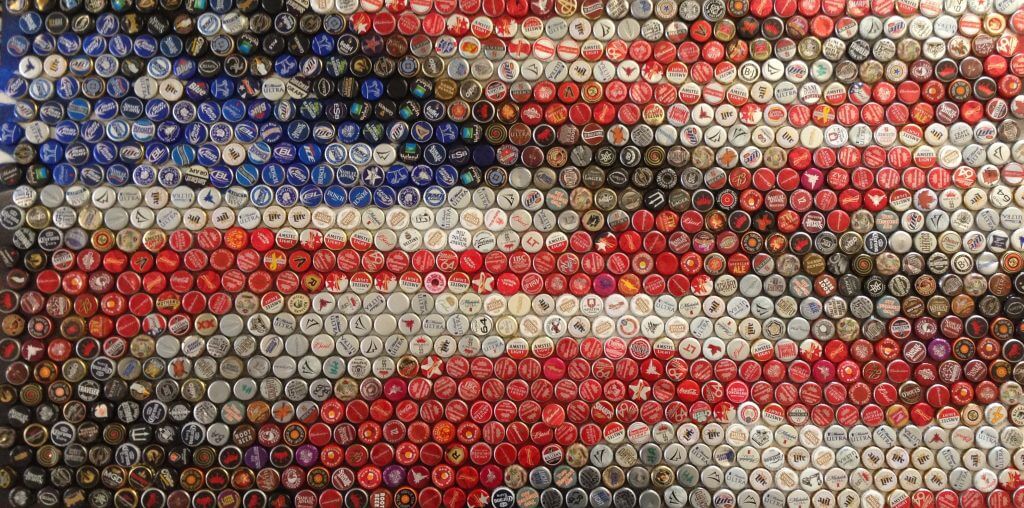

Bottle Cap Artwork

After creating even more mosaics, Nathan found other creations were possible, such as bottle cap roses suitable as gifts or for restaurant tables, and bottle cap globe-shaped hanging ornaments (which have become the main product). All these can be assembled using any combination of colors, brands, and themes. Bottle caps are difficult to recycle, but the upcycling process Nathan has developed makes them effectively 400 times more valuable than aluminum can pop tops donated to Ronald McDonalds’s house, for instance.

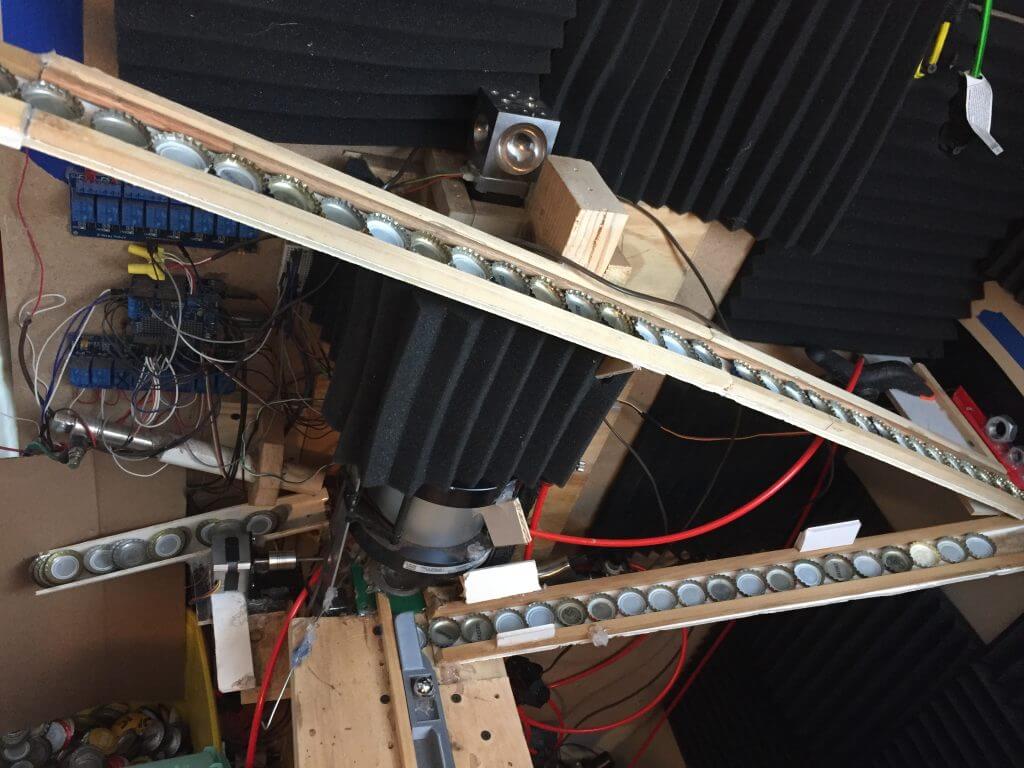

Automation Upgrade

Creating an automated color sorter was an early success. A hobby-grade Arduino microcontroller working with an Adafruit sensor worked well, but the hard part was creating mechanisms to handle a bin full of caps properly. The next step was to develop cap shaping machines to press, hammer, and form the cap into the necessary shape.

Initial designs used 12VDC linear actuators, but soon Nathan found that powerful, fast-acting, and economical pneumatic components from AutomationDirect were a better choice. The Nitra pneumatic cylinders and control valves were used by the mechanisms to work on batches of 100 caps each, with a cycle time of about 60 seconds.

Next-Gen Automation

Now that the current machines supply a steady stream of bottle caps, Nathan is looking to upgrade to a next-generation design using the AutomationDirect ProductivityOpen controller. This will provide the flexibility of Arduino-compatible operation in a robust form factor that operates using standard PLC I/O.

Kaps for Kids is a great example of how end-users and machine builders can use off-the-shelf automation parts and a helpful vendor support system to develop industrial control applications that help their companies run better.

Nathan looks forward to carrying over some existing Arduino programming, even as he takes advantage of the ProductivityBlocks graphical programming language and new capabilities in the AutomationDirect ProductivityOpen controller, like using MQTT for remote visualization, alarming, and data logging.

Click here to read more application stories featuring AutomationDirect products!

All figures courtesy of Nathan Rues