Protective relays are specialized devices designed to sense abnormal conditions in electric power systems, commanding circuit breakers to trip or close when needed. These relays are absolutely essential to the reliable operation of the electric power generating stations, substations, transmission lines, and distribution systems that comprise any large-scale electric power grid; they are increasingly finding application in process industries for the protection of plant-scale electrical power systems and large electric motors.

Protective Relay Education

Despite the widespread application and importance of protective relays, however, technician-level education for protective relays is scarce in the United States. Most relay technicians receive their education either through military programs such as the U.S. Army’s “Prime Power”, the U.S. Navy’s “Muse”, or through apprenticeship programs offered by electrical utilities. Only a handful of public colleges offer any protective relay coursework at the technician (2-year) education level; and Bellingham Technical College (BTC) recently became one of them.

BTC’s Instrumentation Program

Part of Washington state’s Community and Technical College system, Bellingham Technical College is a two-year professional/technical college. Among the various Associate degree program options offered by BTC is Instrumentation and Control Technology. The curriculum for this program is dynamic, changing to reflect the ever-evolving needs of industry.

In recent years, industry advisors for BTC’s Instrumentation program began recommending more exposure to three-phase electrical power systems in the curriculum. Motor controls and variable frequency drives (VFDs) were the first curricular additions addressing this request, and AutomationDirect products figure prominently in BTC’s lab facilities as a result. Thanks to encouragement and support from protective relay technicians at Snohomish PUD, a large public utility in Washington state, protective relays were the next addition to the Instrumentation program designed to enhance students’ understanding of three-phase power systems.

Snohomish PUD generously donated a number of General Electric and Schweitzer Engineering Labs brand protective relays necessary for BTC’s Instrumentation lab, but in order to teach this subject in any realistic capacity those protective relays must have something to protect. In other words, the Instrumentation lab needed its own three-phase power system built on a small enough scale that students could safely operate and test it.

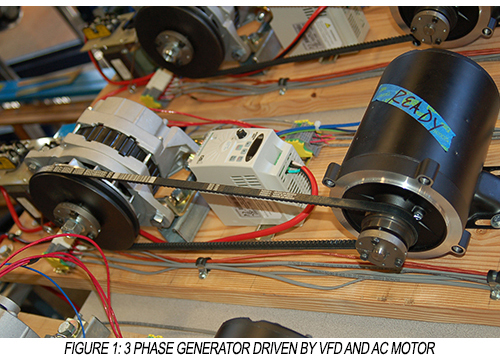

Design work on this project began in early 2014, led by Tony Kuphaldt, an instructor of Instrumentation. The system consists of Delco-Remy alternators (normally used in heavy equipment and big-rig trucks) modified to output three-phase AC power, driven by Marathon AC motors and GS1 series AC drives supplied by AutomationDirect. (Figure1)

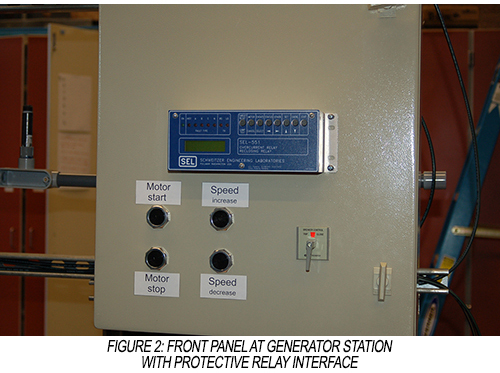

Each generator has a maximum output power of about 200 watts, and simulates the operation of a generating station on a real three-phase power grid driven by some prime mover, such as a diesel engine or turbine. Six of these generating stations were built by students, and then linked together through circuit breakers to a common set of power conductors to form a grid. Students operating the generators must manually adjust the speed of each generator to synchronize it with this grid, and then manually close the generator’s circuit breaker to place it online. A Schweitzer model 551 overcurrent protective relay (Figure 2) installed at each station monitors generator current and trips the circuit breaker if that current becomes excessive.

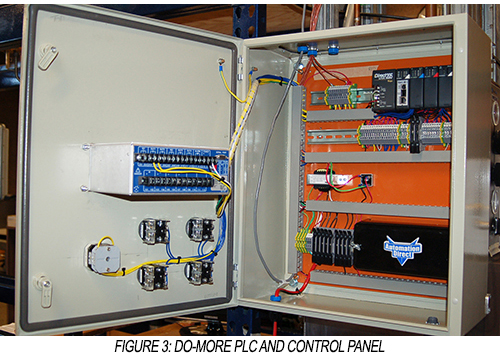

Additionally, each generating station is equipped with an AutomationDirect Do-more PLC (Figure 3) connected via Ethernet to a C-more HMI (Figure 4) to form a SCADA system for this miniature power grid. From the central HMI students monitor generator and circuit breaker statuses, adjust generator (VFD) speed, and record breaker tripping times in milliseconds.

The main factor in choosing AutomationDirect products for this project was price: no other manufacturer of PLC or HMI hardware even comes close to AutomationDirect in terms of cost, and there is no ongoing licensing fee for the AutomationDirect PLC or HMI configuration software.

The ease of digital communication using the Do-more PLC was also a factor in its selection. Not only can the PLC processor be programmed via USB cable, but its Ethernet capability makes the SCADA network easy and fast to set up. Also, its serial Modbus RTU interface allows students to communicate directly to the Schweitzer protective relays. With only a few rungs of ladder logic code, students were able to read integer registers from the relays as well as write bits to them.

In future iterations of this project, each generator PLC will read live phase current data from its protective relay and send that information to a central SCADA PLC which will make load-balancing decisions, sending speed change commands to each generator to ensure the load is equally distributed.

During the summer of 2014, a dedicated Protective Relays course (INST 233) was offered for the first time at BTC as an elective. Students programmed each generating station’s PLC and corresponding HMI screen in the PLC/HMI courses preceding the protective relays course, and then during the protective relays course the students worked on the commissioning, configuration, and testing of the relays themselves.

During the summer of 2014, a dedicated Protective Relays course (INST 233) was offered for the first time at BTC as an elective. Students programmed each generating station’s PLC and corresponding HMI screen in the PLC/HMI courses preceding the protective relays course, and then during the protective relays course the students worked on the commissioning, configuration, and testing of the relays themselves.

BTC’s plan for next year is to expand this miniature power grid to include substations linking the six generating stations to low-power loads simulating customers on the power grid. Once again, each substation will have its own PLC to integrate it with the grid’s SCADA system, allowing students to monitor and control the operation of the grid from a central location.

If you would like to watch videos of this project’s construction and testing, visit the BTC Instrumentation YouTube channel. Simply search the video archive at www.youtube.com/BTCInstrumentation for “Miniature three-phase AC power grid”. You’ll find a number of videos there showing different stages of project completion, as well as important principles related to three-phase AC generators and protective relays.

— By Tony Kuphaldt

Bellingham Technical College

Originally Posted: Feb. 2, 2015