Do you ever think about all those marks and logos on electronic equipment? You should, they’re your assurance of product quality.

Bill Dehner, technical marketing engineer at AutomationDirect and Tim Dunn, design engineer at Host Engineering, wrote an article for the November 2018 issue of Design News titled Why Product Testing and Certification Really Matters, and here’s a summary.

Our homes and plants are full of electronic equipment, and under normal circumstances we don’t worry about a refrigerator, computer or electric motor causing a fire. We take it for granted that these products are built well and tested to ensure safe performance, because most of them are.

Quality-built home and industrial electronic devices have marks indicating they have passed a variety of tests. The UL mark shown here indicates extensive evaluation and testing.

Dehner and Dunn say at least this was the working assumption, but things are changing for the worse with some components, particularly for industrial use.

Some high-quality products are counterfeited outright. Looking at the larger world of manufacturing these days, this type of situation is happening more often for a couple of reasons: the growing interest in devices from the “maker” community, and the growing ease of purchasing inexpensive electronic components from no-name suppliers.

For someone working on a basic industrial project and needing a standard electronic automation device, say a ¼-DIN temperature loop controller, there are many potential suppliers with a wide range of prices. Some searching on eBay can turn up un-branded units which cost barely one-quarter the price of even a high-value supplier, with other name-brand units offered at far higher prices. Be careful, Dehner and Dunn say.

We’ll assume the un-branded unit works, but it will likely have few if any marks showing it has passed any certifications or tests. The customer in this case has no assurance the unit has ever been checked for any type of manufacturing quality outside of powering-up correctly. The more expensive choices will undoubtedly come with an assortment of testing marks such as UL, CE, CSA and possibly others, determined by the country of origin and intended markets.

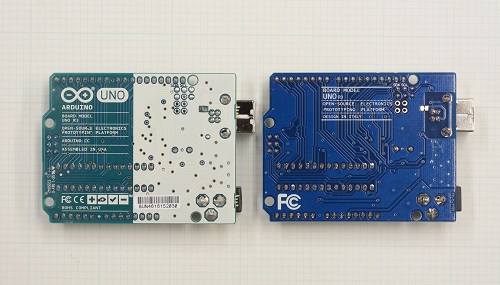

Similarly, someone wanting to use “maker” devices in a project has to be careful as to the source of the products. For example, the basic Arduino UNO, if made by the Arduino company, is provided with the CE (Conformité Européene) and FCC marks. Additionally, it is ROHS compliant. These together designate it meets the most basic requirements for levels of potentially hazardous chemical content such as lead and cadmium necessary for legal sale in the EU countries. The FCC mark indicates it doesn’t cause excessive amounts of RFI.

Those are fine as far as they go, but they don’t mean nearly as much as the kind of analysis and testing done by a nationally recognized testing laboratory (NRTL) such as UL. Moreover, it only applies to products actually made by Arduino.

The bigger problem is an equivalent board can be purchased from multiple manufacturers because the UNO design is open source. Anyone can make and sell a functionally-equivalent board. It may operate exactly as it should, but it may not have any certifications at all. Let the buyer beware.

Two functionally equivalent “Uno” boards, one from Arduino (left) and the other a clone, do not carry the same certifications.

Why Product Testing Matters

Product testing and certifications do not create quality, but they ensure a product is designed and manufactured with quality as a primary objective. Testing always requires using some standard as the yardstick. For example, making sure a PLC can operate without getting excessively hot is part of compliance with IEC 61131-2. The more complex the standard, the more complex the testing.

The internals of an unbranded, non-certified temperature display. It carries no marks at all, so there is no assurance it was designed well, uses quality components or was assembled properly.

Most people who explore this topic in any depth are astonished by the number of testing organizations around the world and the mind-boggling number of standards. These stem from the days before globalization when most industrial countries had their own locally manufactured products.

Consequently, an automation product manufacturer has to launch a testing program for every major country. This creates a lot of duplicated effort, but at least most countries have relatively similar testing criteria. There are differences from country to country and some are stricter than others, but Dehner and Dunn say a truly well-designed and manufactured product can pass most examinations.

Product designers who know their efforts will be dissected under a microscope by a dispassionate evaluator realize they can’t cut corners. Everything has to be executed correctly at every phase of the process. Test and certification are simply a verification of the correct process. Passing the test is important, but not as important as a desire to create and build quality products.