Applying large-scale automation concepts and technologies to a small-scale process operation.

By Doug Reneker

Small-scale distillation processes can take many forms because there are countless possible objectives, but the underlying principles reflect those used by large-scale companies to produce fuel, chemicals, and alcoholic beverages. Boutique and hobbyist practitioners creating products worthy of aging and imbibing generally work from fermented grain mash using corn, barley, rye, or others. They distill first in a “stripping run” using a pot still—where all steam passes directly into a condenser—and then a second time in a “spirit run” using a more selective process.

Our small team wanted to try applying big-industry practices to small-scale process application. We would test using a cost-effective, yet capable, programable logic controller (PLC), human-machine interface (HMI), various instrumentation, and control elements to operate a pilot still for increasing the strength of ethanol for beverage use. Such a “moonshining” application is legally confusing as there are many possible regulations. U.S. federal prohibitions largely remain in effect, although they have been challenged effectively in court. Individual states differ on the topic, and many countries have relaxed regulations. Anyone considering taking this up should research local legal restrictions. Safety is also important, with general hobbyist guidelines recommending against distilling a wash above 40% ethanol. The thought that a home distillation setup can compete on price with commercially available options simply isn’t practical, as is the case with home-brewed beer.

Extracting Success

For those who insist on the hands-on approach, fermented grain mash typically contains about 10% ethanol. Heating this product as a batch in a pot still results in higher-concentration ethanol, and water. Since the mash ethanol content is highest at the start, boiling begins at about 92 C, and this temperature gradually increases as ethanol is cooked off. Distillate “low wines” from this stage are usually around 30% to 40% ethanol.

Performing a spirit run to transform this into higher proof distillate suitable for aging is where things become more complex. Some distillers simply use a pot still for the spirit run, but this results in a relatively low proof. Achieving higher-efficiency may involve using scaled-down industrial processes with trays and bubble plates, easily capable of producing >90% concentrations. For making a neutral spirit (vodka) this is an excellent approach, although with costly equipment. Creating distillate retaining flavor from the mash (whiskey) calls for a lower final proof, but higher than is possible from a pot still.

Purifying the Process

Since small-scale distillers often enjoy designing and building their own equipment, creating a column with accurately controllable efficiency is a basic challenge. One approach is a packed column, where steam moving through Raschig rings or copper mesh packing provides a higher degree of separation than a pot still, in an arrangement simpler than trays and bubble plates. Success depends on creating reflux, where some steam condenses in the column, allowing liquid and steam to flow counter-currently.

To generate reflux, a small condenser called a dephlegmator is placed at the column top such that the produced condensate falls back onto the packing. If carefully controlled, this approach can be highly effective. However, if the dephlegmator is too hot, most steam will pass through and there will be little or no reflux. If too cold, it can choke off steam flow entirely, with little or no distillate recovered. Ideally, the operator should determine what steam temperature, measured at the dephlegmator exit, provides the desired alcohol content. For example, creating alcohol at 80% calls for steam around 83 C, so this should be the dephlegmator exit temperature. Since alcohol concentration below 45% in the boiler below results in a boiling point >84 C, the dephlegmator must cool the steam, but by a specific amount, which means cooling water flow must be controlled.

Refining the Control

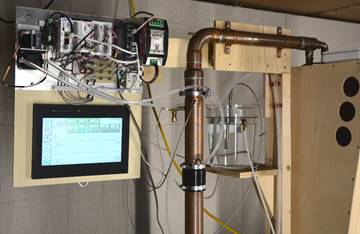

The still setup illustrated (Figure 1) consists of a 10-gallon boiler sending steam through a 2-inch copper column packed with ceramic Raschig rings, then into a dephlegmator (Figure 2) using a small shell-and-tube configuration with four ½-inch tubes. For purposes of this demonstration, we’re distilling commercially produced vodka, diluted to 40%. A resistance temperature detector (RTD) is inserted at the exit to measure steam temperature. Since this value is only a proxy for alcohol percentage, we measure the actual percentage manually at the final delivery point via a proof hydrometer using a parrot (Figure 3). Unfortunately, this value can’t be input directly into the PLC. Conditions may call for adjusting the 83 C setpoint to maintain output at 80% or some other value as desired.

This process is generally stable: boiler temperature gradually increases as alcohol is depleted, so cooling water flow must increase gradually in response. Steam coming through the dephlegmator passes into the main condenser and is captured as liquid at the delivery end.

Controlling cooling water flow has been the main challenge, with several approaches tried:

- Using a needle valve from a pressurized supply. This works, but is highly sensitive to supply pressure and is difficult to control accurately. Regular tweaking is necessary.

- Replacing the needle valve with a small peristaltic pump regulated via a manual speed control. This volumetric solution eliminates supply pressure problems, but still requires frequent adjustment.

- Replacing the pump’s manual regulator with an Arduino capable of proportional-integral-derivative (PID) control to adjust pump motor speed to maintain the 83 C setpoint. Conceptually, this was a major advance, but still erratic and difficult to tune due to long process lag time.

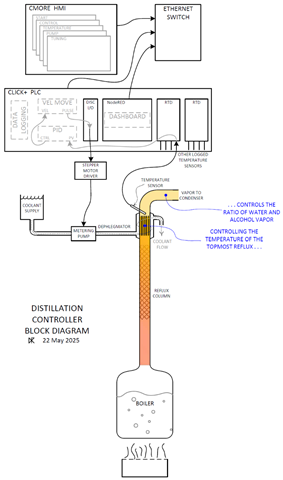

These trials suggested a need for a PLC and HMI capable of measuring and visualizing multiple temperature points, and using these values to modulate pump speed with a stepper motor and PID control (Figure 4). Cloud connectivity via Node-RED allows data logging and monitoring from anywhere. The PLC/HMI/stepper solution provides exceptional control versatility and access to process data:

- Multiple temperature measurement points are trackable, including boiler/steam; steam at dephlegmator exit; cold water supply to dephlegmator; heated water exiting dephlegmator; and ambient temperature.

- Pump speed/cooling water flow and temperature differential allow calculation of heat removal.

- Automatic PID tuning software resident in the PLC helps optimize control.

Figure 4, 5: Our pilot-scale distillation setup uses a CLICK PLUS PLC and I/O, Leadshine stepper drive, C-more CM5 HMI, and other components all sourced from AutomationDirect, to achieve closed-loop control, perform some general process automation, and provide data for analytics.

Additionally, the HMI allows manual inputs, such as indicating when jars are filled at delivery. Common spirit run practice uses small jars (e.g., quarts) and numbering them sequentially as output moves through stages called foreshots, heads, hearts, and tails. As each jar fills, a tap on the touchscreen marks each point on the graphs, providing a record of output. Output slows during the run until it effectively stops.

Trial runs have shown great success with this approach. Commercial off-the-shelf (COTS) hardware has been easy to implement using free configuration software, and barely a dozen rungs of ladder logic were needed due to the built-in PID and math capabilities. An upcoming story will provide more implementation details and results—stay tuned!

All images courtesy of Doug Reneker

About the Author:

Doug Reneker is a retired electrical engineer and circuit designer who worked for Bell Labs, Recon/Optical, and Arris. He has a BS and MS in electrical engineering from Iowa State University. Contact him at reneker@ieee.org .