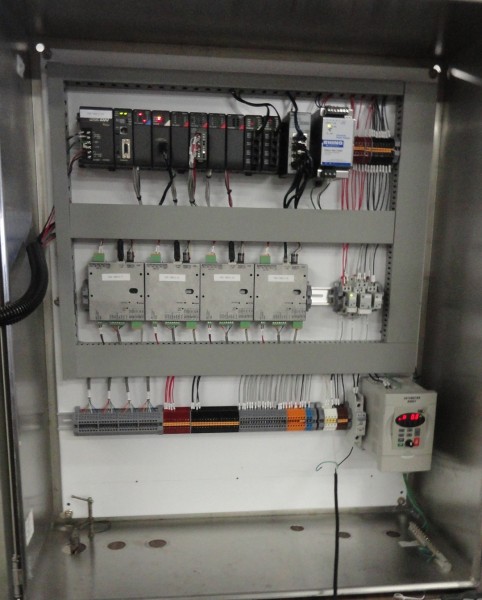

Systems & Controls in Lenoir City, Tennessee, was contacted by a scale manufacturing company to develop a brewed tea and coffee container filling machine using four weight transmitters, a DirectLOGIC DL-205 PLC, a RHINO power supply, a C-more touch panel and a GS2 variable frequency drive.

Using the DirectLOGIC

Using the DirectLOGIC

Mark McHenry and his team automated the system which moves four containers at a time onto the liquid filling system. Once in position underneath a fill head, a scale platform underneath each of the containers is raised and the fill heads are simultaneously lowered into each of the four containers. The DL-205 signals each of the four weight transmitters to perform a tare weight operation. Using the C-more touch panel, machine operators can adjust target weight percentages as needed. When each of the scales reaches tare weight, the DL-205 activates a pump and the valves for each station open.

To prevent excessive foaming of the liquid during filling, the PLC controls the variable frequency drive on the pump in order to perform a slow/fast/slow filling operation.  This process happens each time a container is filled, in order for the pressure to remain consistent whether filling all four containers or only one. Once the liquid filling cycle is complete, the scale platforms lower, the conveyor transports the finished product, and the process repeats.

This process happens each time a container is filled, in order for the pressure to remain consistent whether filling all four containers or only one. Once the liquid filling cycle is complete, the scale platforms lower, the conveyor transports the finished product, and the process repeats.

Systems & Controls specializes in custom control systems mainly focused on weight-based batching and filling processes. Working with various equipment manufactures as well as local fabrication shops, they incorporate some of the best products on the market into their systems.

For more articles about programmable control, click here.

Disclaimer: AutomationDirect does not guarantee the products described in this article are suitable for your particular application, nor do we assume any responsibility for your product/system design, installation, or operation.

Originally Published: May 2014