Michael Miles and Investors (M.M. & I.) has been in the commercial and industrial electrical markets since 1986. The company began by offering Web-based database and Visual Basic applications supporting school systems. In 1994, we ventured into the computer market, becoming proficient in information technologies and high level programming. In 2002, we saw a need in the market to combine our IT programming services with our PLC/Controls and controls programming. This allowed us to offer our customers the ability to get factory information up into the IT world, over intranets or even over the Internet. We also added a panel shop, giving us the ability to provide complete “turnkey” solutions, with all the control components mounted and wired in a panel. We are also uniquely suited to offer reliable yet affordable UL certified motor control solutions containing integrated data collection and reporting; this technology does not require an IT department to maintain.

Installing a Control and Data System

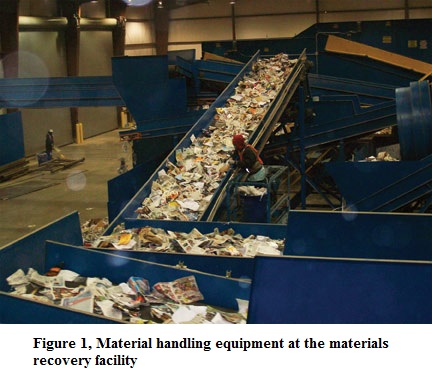

Several months ago, Pratt Industries, one of the industry’s largest manufacturers of paper and corrugated products, and a company committed to recycling, approached us to install a control and data collection system for a new material recovery recycling plant being built in Shreveport, Louisiana. A sister plant was being implemented in another location, and controls were being installed there by another firm, but they wanted a second solution for comparison. Their request was not only to provide the automation and controls, but to make plant information available to their management teams on a 24/7 basis from anywhere in the world using Web technologies.

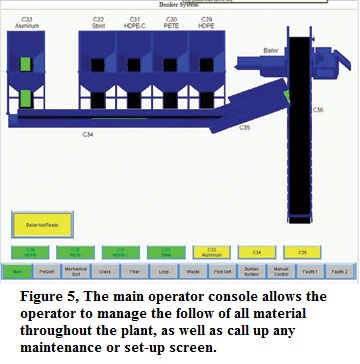

A material recovery recycling plant is quite simple. Recyclable material such as cardboard, plastic, glass and aluminum cans arrives at one end of the plant, usually all mixed together from a variety of sources. The plant uses many sorting devices, including screens, magnets, separators, magnetic conveyors and scanners, that sort and separate each of the disparate materials, then convey the material to a series of balers. Each of the materials is baled and moved to their own processing plants, or sold to other plants for producing finished goods and products with recycled content.

A material recovery recycling plant is quite simple. Recyclable material such as cardboard, plastic, glass and aluminum cans arrives at one end of the plant, usually all mixed together from a variety of sources. The plant uses many sorting devices, including screens, magnets, separators, magnetic conveyors and scanners, that sort and separate each of the disparate materials, then convey the material to a series of balers. Each of the materials is baled and moved to their own processing plants, or sold to other plants for producing finished goods and products with recycled content.

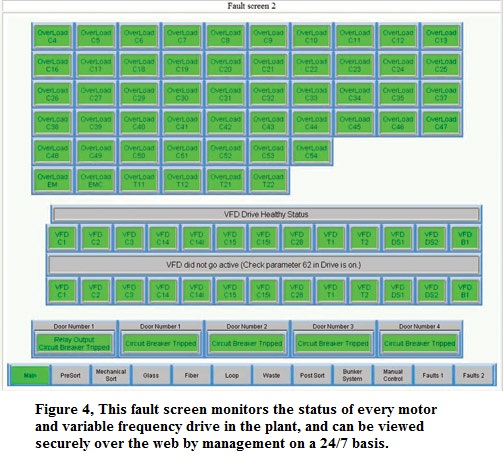

While the plant footprint was quite large, we were able to consolidate the controls to a single four-bay control cabinet. Over 65 AC induction motors are used in conjunction with numerous variable frequency drives to control the various conveyors, material handling equipment and processing equipment. Our client wanted the capability to monitor each of these motors, their status, any faults, and be able to view and change variable frequency drive parameters.

AutomationDirect Products Selected

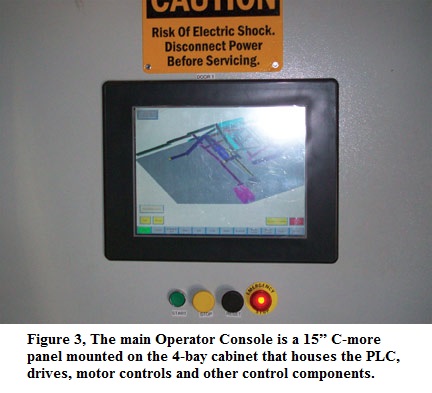

We selected AutomationDirect to provide the core of our automation solution, principally due to their “ease-of-use” and flexibility. All of AutomationDirect’s components use Ethernet as the network topology; this provided the flexibility to add the plant networking, as well as the upstream communications. We used several C-more touch screen operator interface panels at various locations throughout the plant; information from each panel is readily available in real-time. We installed C-more touch panels in the pre-sort area, post-sort area, baler, and the main operator console. Each C-more panel is networked via Ethernet to the main PLC, which is a DirectLogic D2-260 unit with two racks of I/O installed. The PLC system also communicates via Modbus (over Ethernet) to 16 AC variable frequency drives. We installed a DL06 unit to serve as an “E-stop” PLC dedicated to monitoring the E-stops; it captures the fault conditions and reports them to the main control system. This PLC also communicates via Ethernet to the main D2-260 PLC.

As a committed recycling company, Pratt ultimately plans dozens of these material reclamation centers nationwide. Since these will be geographically dispersed, their management team had a requirement to acquire up-to-date information and instant production data from anywhere in the world. The C-more panel has an FTP function that allows us to transfer production data, status information, up-time and down-time statistics,C-more screen captures, trend graphs, and data securely to a server at our facility. We wrote custom software that allows Pratt management the ability to securely and instantly look at nearly any data, any C-more screen, and production statistics, over the Web.

The AutomationDirect control system provided all the connectivity we needed in a control system that included 67 motors, 16 variable frequency drives, four C-more touch screen operator interfaces and a mid-range PLC system. We were able to use the FTP transfer function from C-more to provide our customer with the ability to continually monitor production data, plant statistics and fault conditions, all securely over the Web. In the end, the solution achieved all goals the customer had outlined, and we are continuing to add remote monitoring features at the customer’s request, while enhancing the solution that we already have in place. We will be adding the C-more remote feature in the near future which adds additional capabilities to the system. We were extremely pleased that AutomationDirect added this feature which greatly enhances our solution, and we are able to offer it to any of our customers with a simple download.

By Michael Miles

Founder/President

Originally Published: Dec. 1, 2010