Many process plants use batch operations for all or part of their production operations. Some processes are inherently batch oriented, but many others can be converted to continuous. Converting a batch process to a continuous operation has many advantages including, but not limited to, better quality, more throughput and less energy use (see Table 1).

These advantages are real, concrete and have been proven in thousands of process plants worldwide. But there’s a catch, and it’s the complexity inherent in converting a process from batch to continuous.

This article features input from numerous end users and system integrators, all recounting their experiences in converting from batch to continuous. Benefits will be examined first, then challenges will be detailed. Finally, solutions will be suggested including a look at how AutomationDirect’s new Productivity3000 controller may be used to control continuous operations.

Benefits of Upgrading from Batch to Continuous

Upgrading all or part of a process from batch to continuous yields many benefits. “Continuous operations yield more consistent product quality, more predictable behavior and a better opportunity to maintain and perfect a steady-state process,” said Carl Wikstrom, PhD and PE in Control magazine’s September 2009 cover story, “Batch to Continuous.” Wikstrom is the director of research and development at Rineco Chemical Industries in Benton, Arkansas.

Another end user quoted in the same Control cover story agreed with Wikstrom. “Our continuous polyether polyol reactor is about one third the size of a comparable batch reactor, yet it can produce 1.5 times as much product,” related William D. Wray, PE, engineering consultant with Bayer MaterialScience in Channelview, Texas.

“The continuous reactor also features increased energy efficiency as there is less time and energy spent heating and cooling reactor contents as compared to a batch reactor. Pound for pound, our continuous process uses about 25% of the energy used for the batch process,” added Wray.

Mark Hron, a cheese and dairy electrical engineer with Kraft Foods, noted the following benefits in the cover story. “You can slow down or speed up production to match packing line speeds. Filling and emptying time lags can be reduced. Less operator input and interaction is needed, so labor is saved”.

End users aren’t the only ones on board with the benefits of switching from batch to continuous. System integrators agree, and they look at the advantages from their client’s point of view.

Integrators Agree

System integrator Bachelor Controls (www.bachelorcontrols.com) is headquartered in Sabetha, Kansas. Working with a brewer, they converted a fermentation process from batch to continuous (see Figure 3). “The new process has resulted in much more consistent alcohol production,” said Marvin Coker, senior project engineer with Bachelor, in the Control cover story.

“The brewer has seen reduced fouling in the beer still. Clean-in-Place costs have been reduced dramatically as between-batch cleanings have been completely eliminated. There’s also been a reduction in raw material costs as the client has not had to pitch yeast into the process since the project went online,” added Coker.

“The brewer has seen reduced fouling in the beer still. Clean-in-Place costs have been reduced dramatically as between-batch cleanings have been completely eliminated. There’s also been a reduction in raw material costs as the client has not had to pitch yeast into the process since the project went online,” added Coker.

Another systems integrator seconds Coker’s experiences. “Continuous production minimizes intermediate storage of in-process materials that often have relatively low shelf life,” noted Delmar Schmidt in the cover story. Schmidt is an applications engineer with Melfi Technologies (www.melfitechnologies.com) in Ontario, Canada. “Significant safety improvements can also be realized if these in-process materials are toxic or explosive,” added Schmidt.

Optimation Technology (www.optimation.us) of Rush, New York, converted a 90,000 gpm 17-cell industrial cooling tower water makeup system from batch to continuous. “A shift operator spent half his time adjusting makeup water to the towers via 17 valves,” observed Dan Curry, senior process control engineer with Optimation, in the Control cover story.

“Chemicals for water treatment were also added periodically by operators. The manual/batch operation of water and chemical addition resulted in large quantities of wasted water and water treatment chemicals, as well as inconsistent water temperature and chemical concentration,” noted Curry.

“The cooling towers and associated water headers were segregated into five groups and a level transmitter and control valve were used to automate water makeup and chemical additions,” explained Curry.

“Benefits included reduced operator involvement, reduced energy consumption, and reduction of heat exchanger and piping fouling due to lower chemical concentrations. Fewer chemicals were sent to the sewer and less water was sent to drains. Finally, the new system exhibited improved stability of chilled water supply temperature and lower demand of water from the central plant,” concluded Curry in the cover story.

System integrators and end users agree that the gains from switching from batch to continuous are significant. But as we’ll see, so are the automation challenges.

More Precise Control Required

Continuous systems require more precise control than batch processes. “With continuous operation, the control system needs to be able to correct more quickly, reliably and robustly to changes from steady-state,” noted Wikstrom in the Control cover story.

Batch systems inherently include opportunities to pause and make corrections, but continuous processes don’t. “We no longer had the luxury of just pausing equipment, so we had to develop isolation strategies to keep an upstream issue from affecting the downstream processes,” said an automation engineer with a pharmaceutical company in the cover story.

For brewery fermentation processes like the one previously discussed in this article, level control for fermenter tanks was problematic. “In a typical process, a loop response time might range from a few seconds to a few hours, but this project often had loop cycles of 24 hours or more. Inventive advanced process control techniques were developed to deal with these significant time lags,” related Coker in the Control cover story.

“These techniques consisted of using much smaller gains, and then adjusting the bias for the PID loop based on the differences in the control variable (CV) output to the valve for the upstream and downstream fermenter level controls,” added Coker.

“Since the flow cascades through the four fermenters to the beer well, the flow out should match the flow in. Flow metering was not available between fermenters, so the differences in the CVs were used to approximate flow and the loop was biased based on that difference,” explained Coker in the cover story.

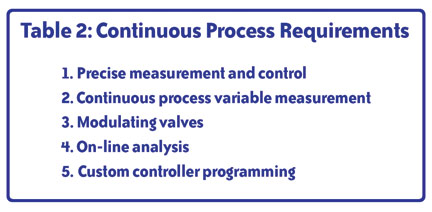

As recounted above, continuous processes require precise control. Continuous on-line measurement of process variables is also needed, often requiring a significant upgrade from off-line measurements.

In the Control cover story, Hron of Kraft Foods discussed continuous control measurement issues. “There can be problems when going from a single scale in a batching system to multiple flow meters in a continuous system. Often, extra calibration work is required along with more data monitoring. Most seriously, continuous processes may need sensors that just don’t exist.”

Because of the complexity inherent in continuous control, low end PLCs and other controllers are usually not up to the task. What is needed instead is a process automation controller (PAC) with high I/O capability, high speed, advanced control capability and sophisticated communications.

Productivity 3000 a Great Fit

AutomationDirect’s Productivity3000 PAC brings many features well suited for conversion of processes from batch to continuous. “Continuous processes often need expandability and a large I/O count,” says Jeff Payne, product manager of PLC, I/O and PC Based controls at AutomationDirect.

The Productivity3000 gives process plant automation professionals the capability to add up to 32 Remote I/O slave bases to the main CPU. Users can also add four expansion bases to the CPU, and four expansion bases to each remote slave. The modular design allows selection of a base size from three, five, eight or eleven I/O module slots.

“Combining the large number of allowable bases with our high density I/O modules, up to 64 points per module for 24VDC inputs or 24VDC outputs, creates a system that can control and monitor many data points. The Productivity3000 can also be used to adjust system controls on the fly for real time process adjustments,” adds Payne.

“Greater processing power, fine tuning PID loop control, and advanced math and data statistics instructions give users the tools required for control of continuous processes,” explains Payne.

Continuous processes are usually more heavily instrumented than batch processes, and many of these instruments and analyzers aren’t available with standard communication ports and protocols. “The addition of our Custom Protocol Instruction greatly simplifies the task of interfacing the Productivity3000 with the process analyzers and proprietary instrumentation required in many continuous process applications. Without this feature, establishing communications to these devices would require the addition of costly hardware along with many hours of complicated coding,” concludes Payne.

For processes that can be upgraded from batch to continuous, benefits are significant. Making the upgrade raises numerous automation issues – but these can be addressed with the right combination of hardware, software and intelligent engineering. Process plants that convert from batch to continuous will reap the benefits and be rewarded for their efforts.

By Dan Hebert

The Hebert Agency

Originally Published: Dec. 1, 2010