Even desktop- and garage-sized process and manufacturing applications can benefit greatly from automation, but only when the right products are available to help designers easily create a solution. This Control Design October 2025 article titled How to Apply Industrial Control to Small-Batch Distillation: A Case Study in Smart Reflux Automation followed a small team as they applied industrial-grade PLC, HMI and other automation products to create an efficient distillation system.

Refined Process Control

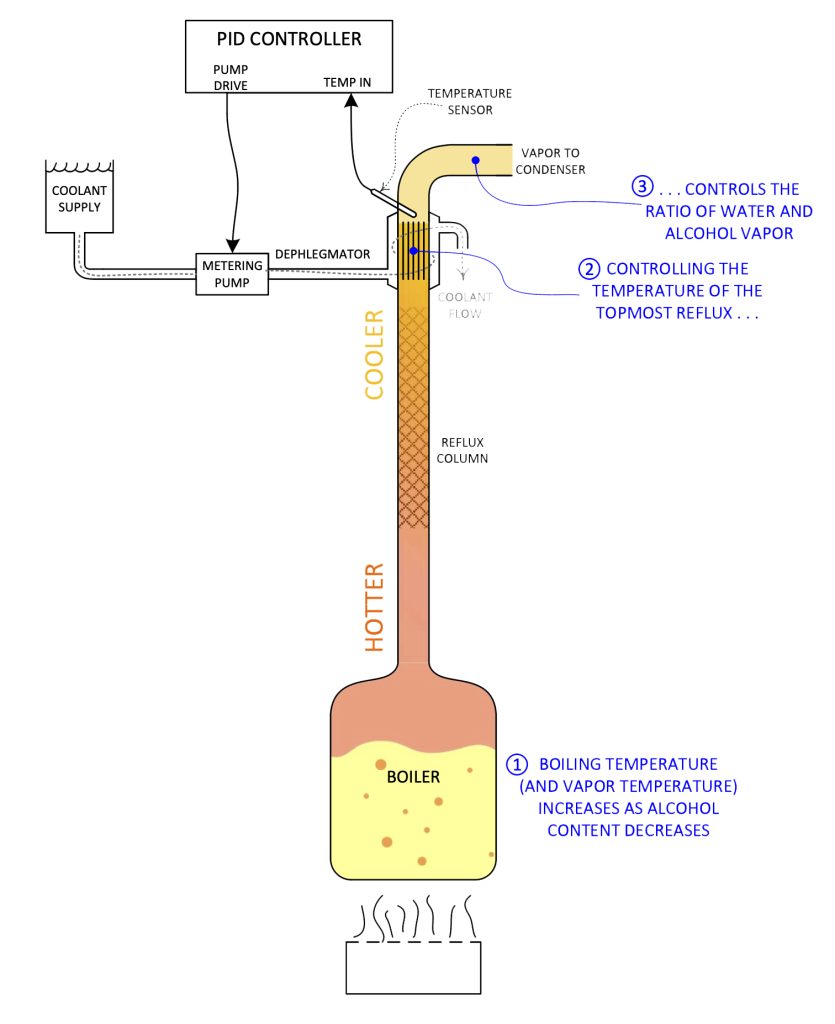

The distillation process begins with a fermented mash (~10% alcohol by volume), initially concentrated in a stripping run to about 30–40% alcohol. A subsequent spirit run in a distillation column further refines the product to the required proof. Key to efficient separation of alcohol from water is the use of a distillation column with trays or packing, and a dephlegmator—a shell-and-tube heat exchanger at the top of the column—to control reflux and provide precise separation by maintaining optimal vapor temperatures.

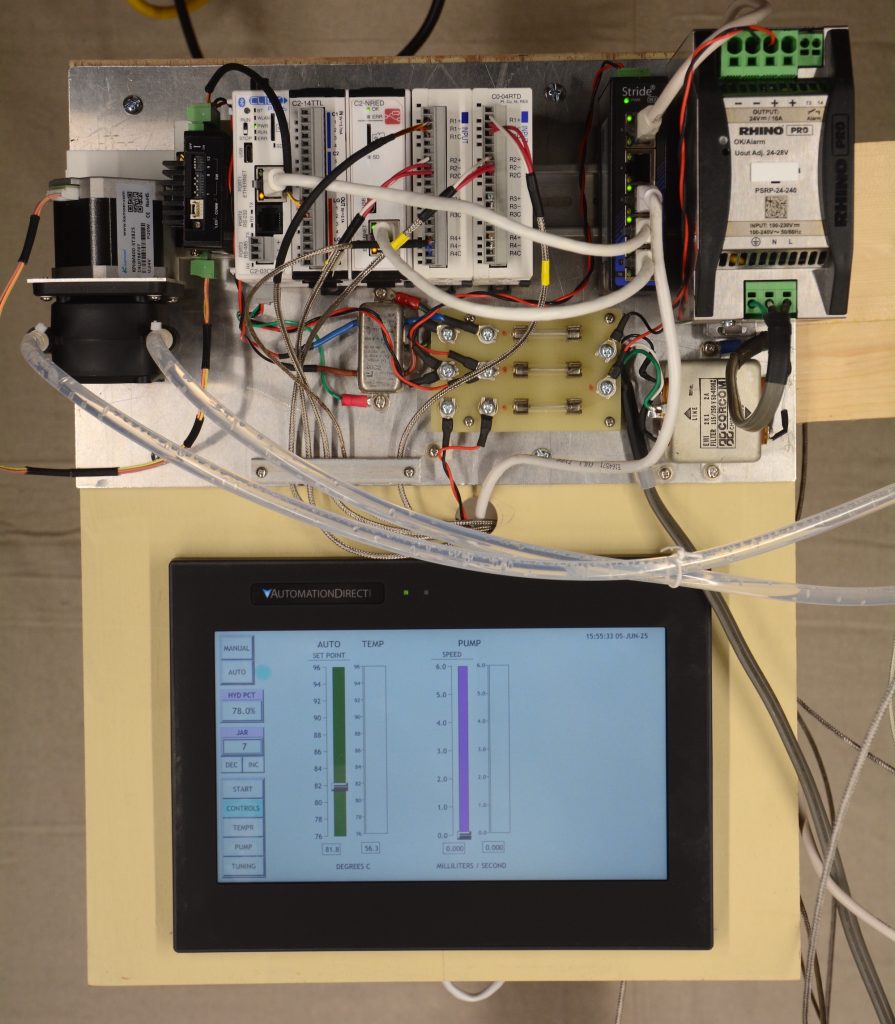

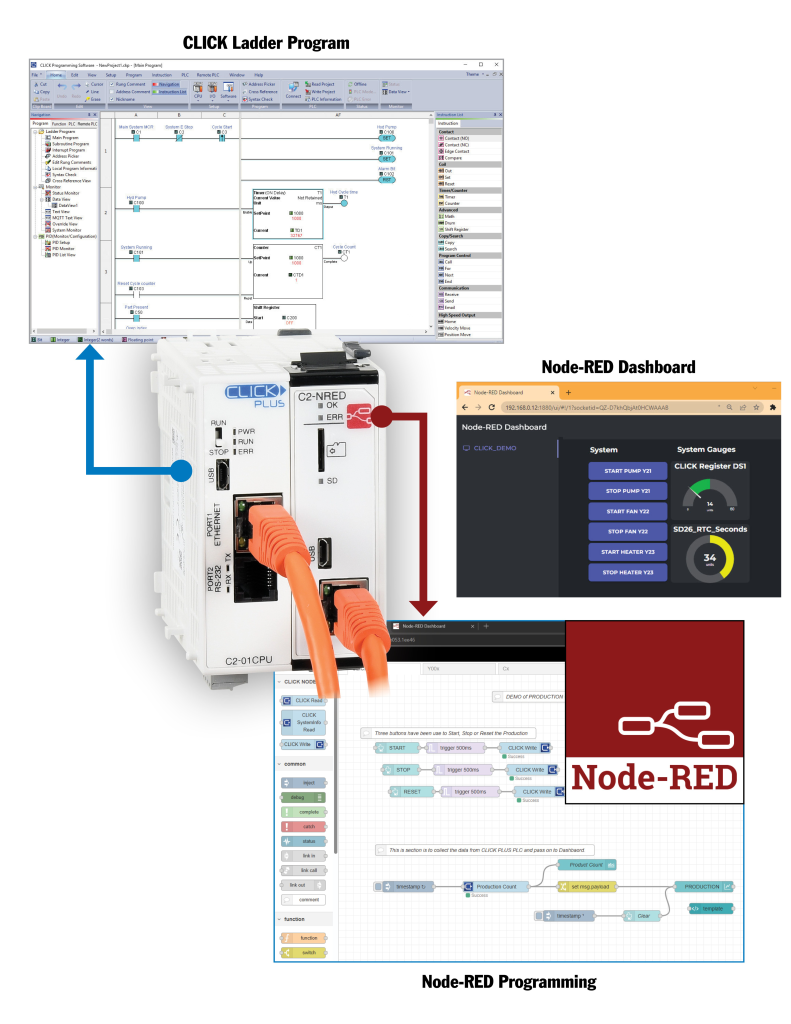

By integrating a programmable logic controller (PLC), human-machine interface (HMI), stepper motor drive, instrumentation, and associated data communication technologies, the project demonstrates how complex automation solutions typically reserved for industry can be effectively adapted to artisanal-scale operations.

Top Shelf Automation

To automate the process, the team selected the AutomationDirect CLICK PLUS PLC and C-more CM5 HMI, integrating them with RTD temperature sensors placed at critical points: the boiler, column top, condenser, and dephlegmator. The system uses a stepper motor-driven peristaltic pump to finely control the flow of cooling water through the dephlegmator, which is essential for maintaining the desired vapor temperature and thus, the alcohol concentration.

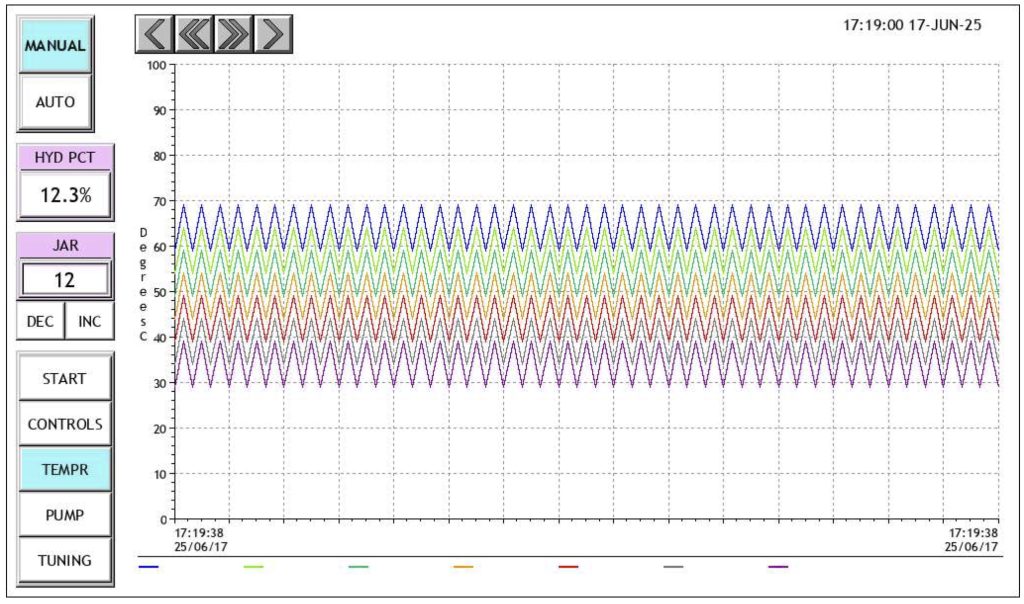

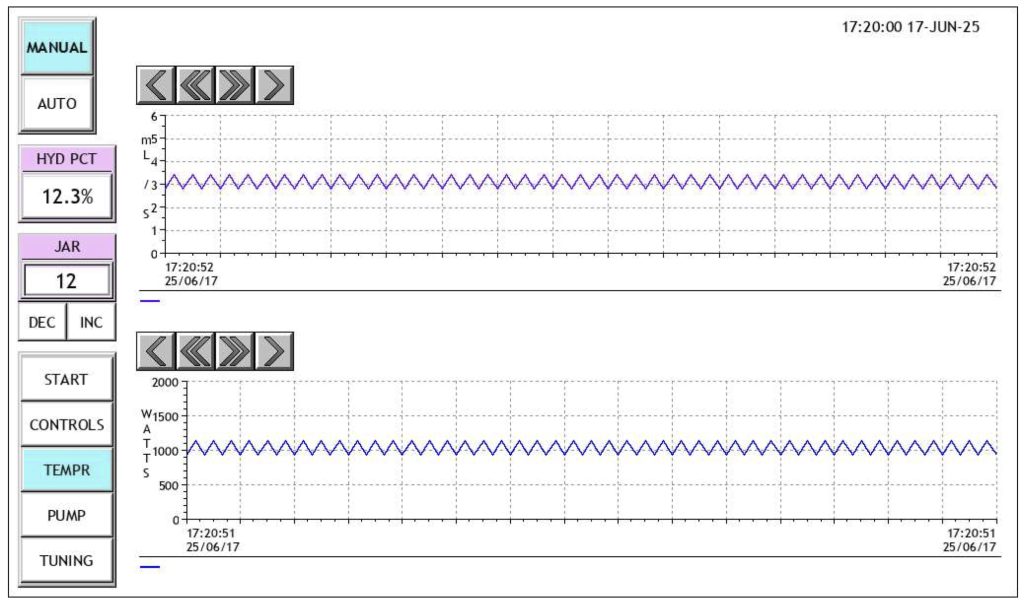

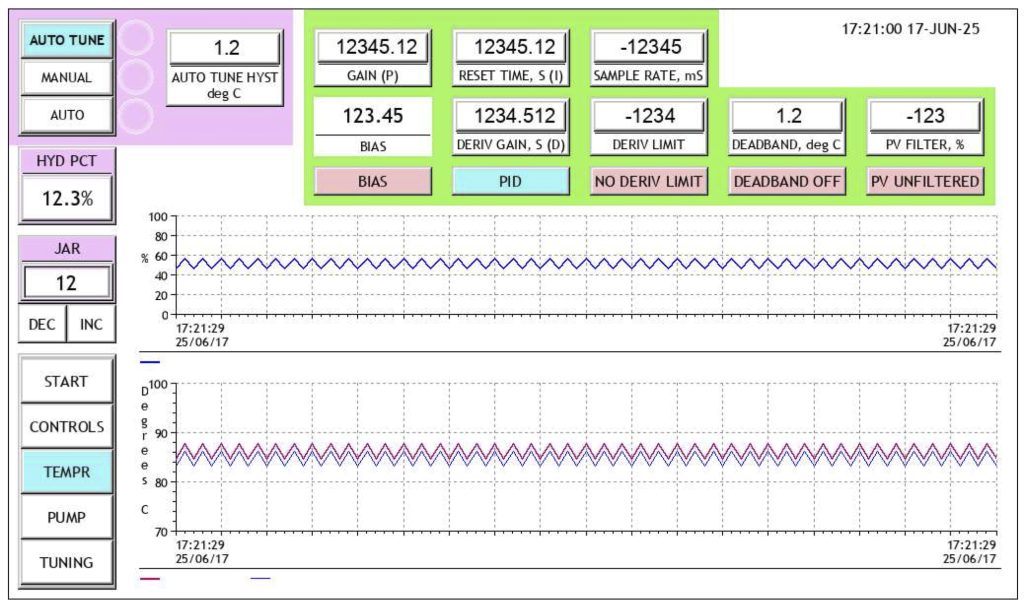

The PLC executes PID (proportional-integral-derivative) control, including auto-tuning capabilities, ensuring that the system can control cooling flow in real-time as the batch progresses and alcohol content declines. HMI screens provide clear visualization of process variables, including real-time temperature trending, pump speed, and calculated cooling rates (in watts). The control screens allow for both manual and automatic (PID-based) operation, parameter tuning, and comprehensive data logging.

A Node-RED module further expands connectivity, enabling live process data to be displayed on web dashboards, and allowing future integration with broader data networks or external information sources.

Crucially, the project highlights how temperature setpoint management directly influences the final alcohol content and flavor profile—which is very important because too high of a concentration results in flavor loss, especially when producing spirits other than vodka. The automation system logs relevant data, such as jar numbers and alcohol concentration, for traceability and process optimization.

Proof in the Product

The test runs validated the system’s effectiveness. The auto-tuned PID loop maintained vapor temperatures within fractions of a degree, adapting to process changes without manual intervention.

All in all, the project proved to be a straightforward development, with quick integration of the controller into the distillation apparatus, proving that industrial-grade commercial off-the-shelf (COTS) automation devices like PLCs, HMIs and motor drives are accessible and cost-effective to create premium solutions even for small-scale processes and systems.

For automation tasks large or small, check out the AutomationDirect website to find a complete range of electrical, control, instrumentation, and other products, backed by a comprehensive collection of data sheets and support resources, to help you achieve industrial-grade results.