Many types of legacy equipment can last for decades from a mechanical standpoint, but periodic digital upgrades are necessary to keep these systems running efficiently.

A significant amount of machinery used in manufacturing industries is built using electromechanical components that can be readily repaired or replaced to keep capital equipment in service for many decades. However, some of the digital technologies used by this equipment can become unavailable or incompatible over the course of just one. Scott Martin, founder of KCC Software, describes in his Automation.com April 2023 article, titled Automation Upgrades Extend Equipment Life, how he is supporting end users with automation upgrades to extend the life and increase the performance of their valuable systems.

Giving equipment a second life

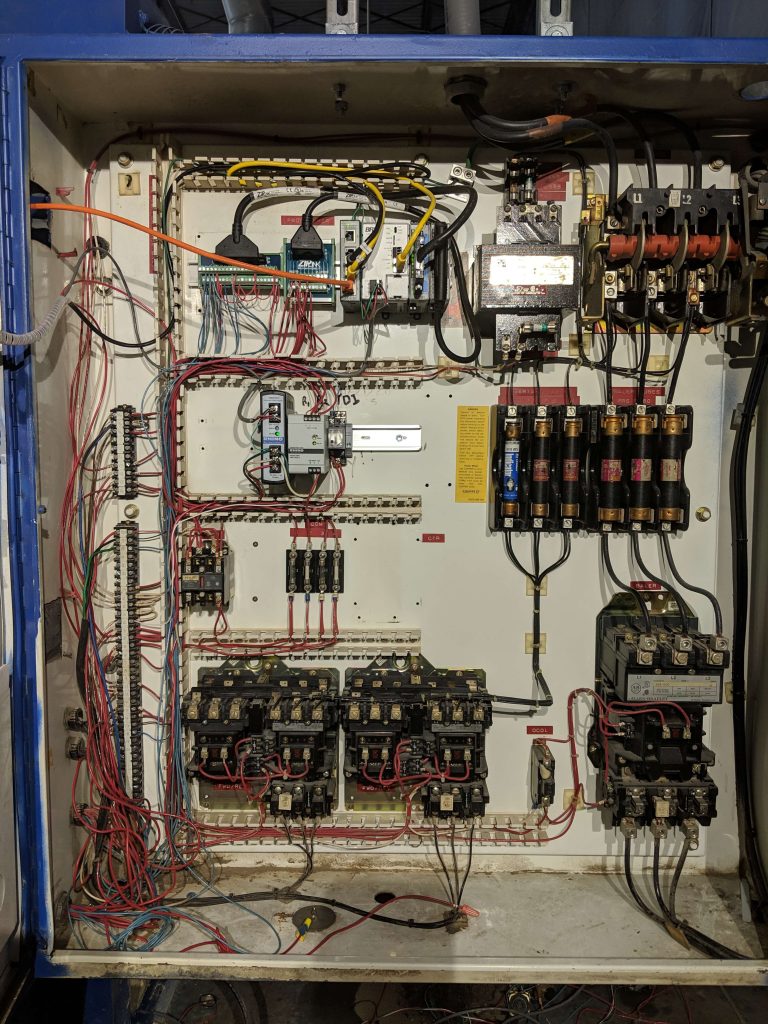

Most industrial equipment is built for the long haul. However, if the electronic components fail—due to heat, age, or power surges, for example—it can be impossible to source replacements. KCC Software is a systems integrator (SI) that recognized this opportunity to help end users, OEMs, and even other SI partners provide automation retrofits that not only keep equipment in service, but upgrade its performance.

Gas controller retrofits

Some industries including semiconductor, solar panel, and LED manufacturing use gasses handled by storage, distribution, and delivery systems. Some gases are inert, but others are toxic, flammable, or caustic. The mechanicals can be maintained indefinitely, but some specialized microprocessor controls were developed in the 1990s or earlier.

Ripping and replacing entire systems is exceptionally expensive and time consuming, while taking no action can result in unplanned outages of unknown duration. However, a carefully planned retrofit using commercial off-the-shelf (COTS) components—like programmable logic controllers (PLCs) and human-machine interfaces (HMIs)—can provide the upgrades needed in just one shift.

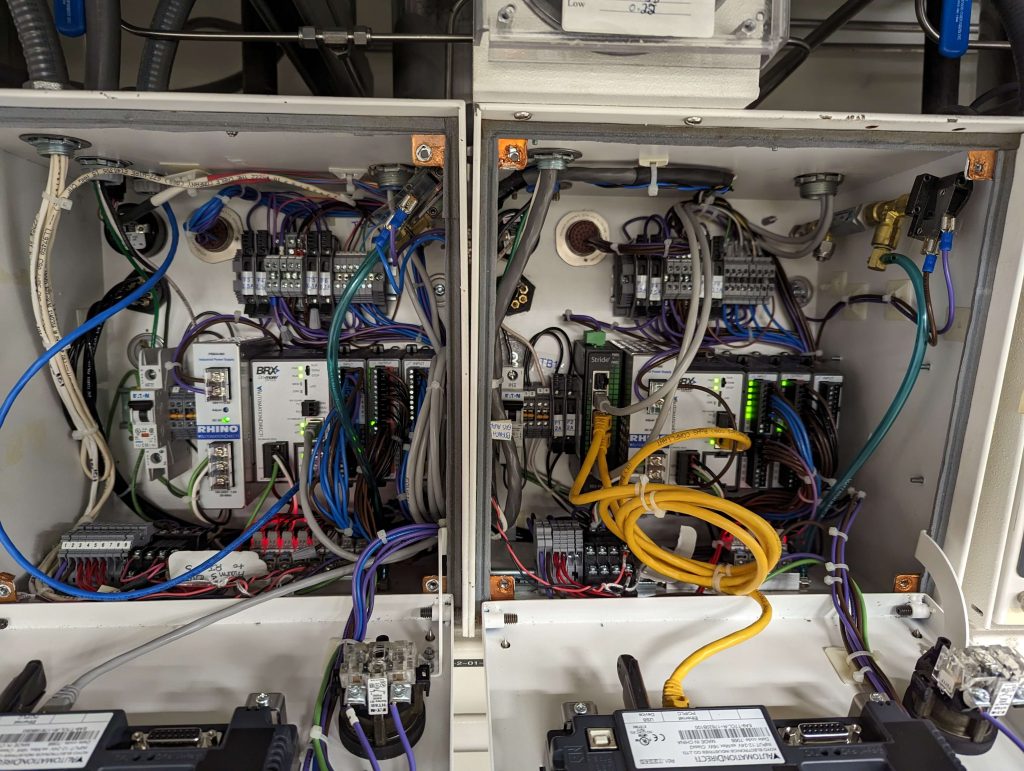

KCC has found that AutomationDirect BRX PLCs, C-more HMIs, and associated STRIDE Ethernet switches are a compact and powerful combination for these types of upgrades.

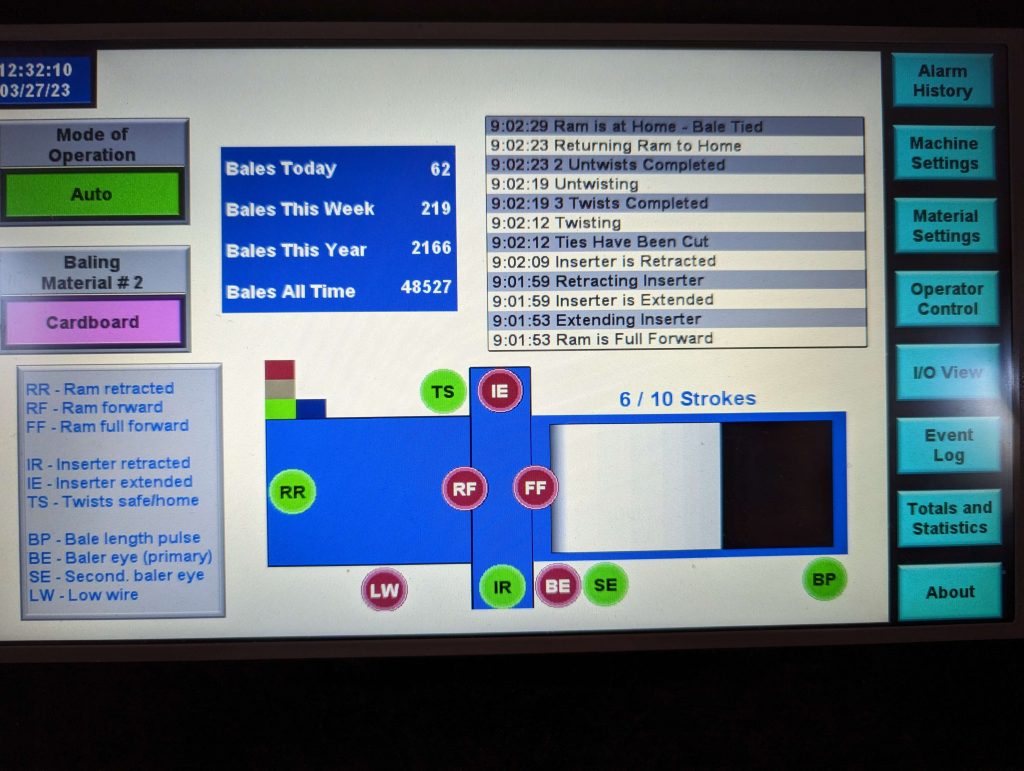

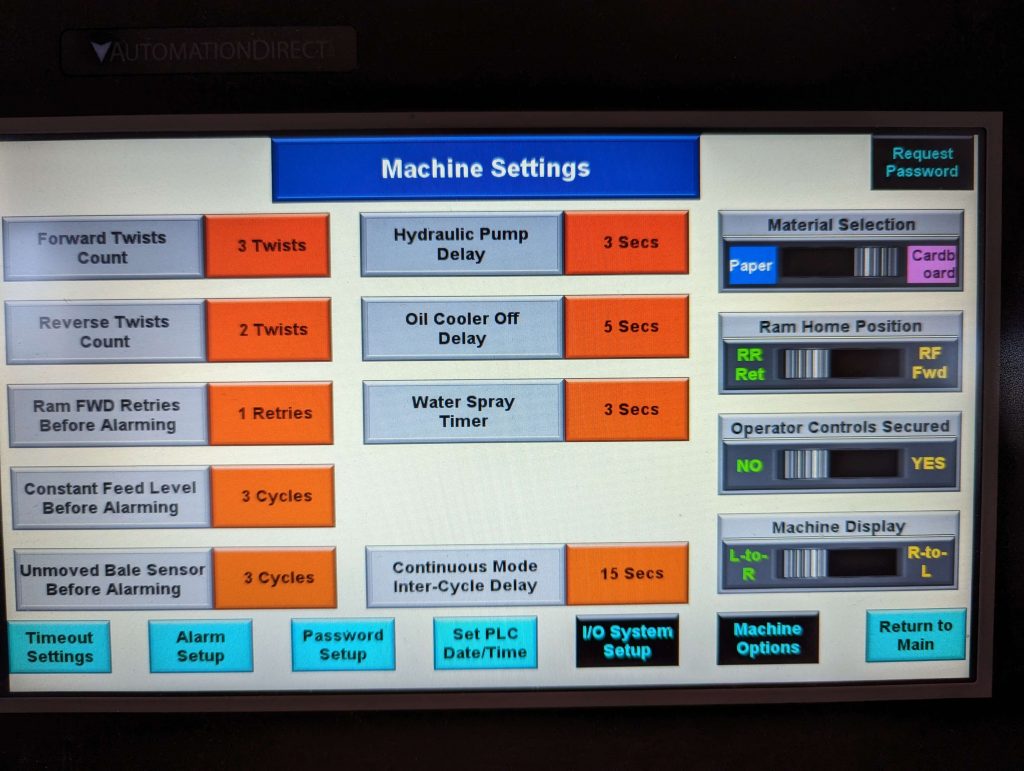

KCC used a similar component combination to upgrade hydraulic bailers used to compress scrap cardboard and other materials. Some of these systems were built in the 1950s and remain in service today thanks to simple controls upgrades.

To achieve this, KCC developed a typical master program that only needs to be configured—as opposed to re-programmed—during installation. The updated automation provides new enhancements, configuration settings, and diagnostics for users.

KCC is focused on supporting clients and keeping their systems running, and AutomationDirect is an important part of their success.

AutomationDirect products and technologies, backed by extensive online documentation, resources and phone/internet support, have played a key role in our work. We have consistently relied on PLCs, HMIs and other automation products from this supplier and have always been satisfied by their performance and reliability. Our business has expanded throughout many industries using these components.

Visit the AutomationDirect.com website today to explore products that can help your company keep essential systems in service.

All figures courtesy of KCC Software