Full coverage E-Stop protection around your machinery

We all know the importance of having emergency stop devices near and around machinery. There are numerous regulations (ANIS, ISO, IEC) that define emergency stop device requirements. In short they all state that they are actuated by a “single human action”, should be used to de-energize equipment to a safe state, and require a manual reset before equipment can be restarted.

Normally when we think of emergency stop (E-stop) devices we think of the simple emergency stop pushbutton. You know the large, red, mushroom-head pushbutton we frantically can press when something is wrong (someone is about to be hurt). They usually do the job just fine in simple machines and when ergonomics allow the operator to quickly and easily get to that particular pushbutton without any additional effort.

Larger Machinery and Challenging Ergonomics

What do you do when you have a large piece of machinery that you need to protect with E-stop devices? Say you have 100 feet (or longer) of conveyor? Say that 100 feet of conveyor might make a few turns or curves? What about other machines, even smaller ones, such as ones around work cells where an operator has to move a few steps in either direction around barriers? These are situations where just adding E-stop pushbuttons will result in a large number of devices just to have E-stop protection coverage. Remember, they have to operate with a single human action so it can’t involve an operator making several steps and navigating around a building column or other pieces of machinery. Overall just adding E-stop pushbuttons in these scenarios could result in excessive wiring and unnecessary complexity to the system.

A great option for the above-mentioned installations is Cable-Pull Safety switches. Cable-Pull Safety Switches are also known as E-stop pullcords, E-Cords or Emergency cable stops. Mounting one device allows the designer of the safety system, by using a length of cable, to cover anywhere from 15 meters with the most basic devices all the way up to 100 meters.

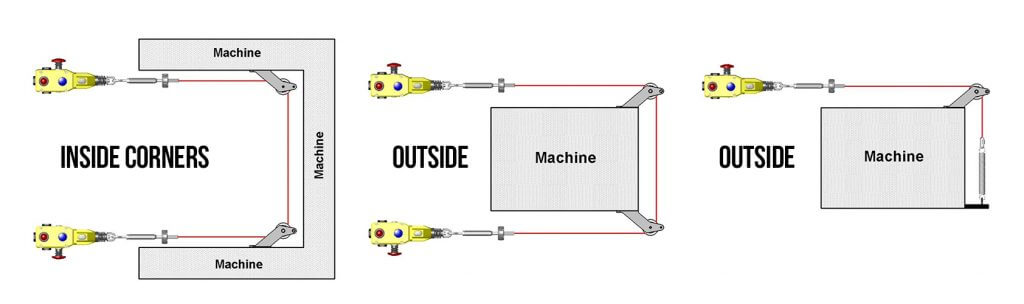

These devices also allow you to go around curves of the conveyor or machinery by using pulleys to allow the cable to move smoothly without binding.

They also incorporate a slack detection feature to prevent tampering. What this means is that the cable needs to be present and connected to the actuator with the appropriate slack in order to operate. If the cable is pulled (too tight/not enough slack), the unit will trip and open its safety contacts. Also, if someone decides to cut the cable to prevent the E-stop circuit from shutting down machinery the actuator will detect that not enough slack is present and trip as well.

Planning your system

To plan on where you are putting your Cable-Pull Safety switches you will first need to layout everywhere an operator may need to activate an E-Stop device. Take a plan view of your machinery or work area and mark this. Next, determine the overall length of the area to be protected. Remember there are several options as far as length of protection is concerned and you can go around curves but will need to use pulleys. After the overall length is determined you might have to break this down into several sections using several Cable-Pull Safety switches. Now you will select your devices, cables, and associated installation hardware. For more in-depth details on design considerations and installation of Cable-Pull Safety switches take a look at the product inserts for the items we sell.

To purchase Cable-Pull Safety switches, other emergency stop devices, E-stop relays or any other safety products visit us at AutomationDirect.

Click here to read more articles related to cable-pull safety switches.