Often regarded as the fourth utility after electricity, natural gas and water, compressed air is widely used in manufacturing facilities. AutomationDirect’s new eBook, “Pneumatics: A Practical Guide” is designed as an easy-to-read guide for users new to pneumatics and explains the basics along with the “why” and “how” pneumatics are used.

+Tech TopicsAutomation NotebookeBookIssue 34 - 2016Learning ResourcesNotebook IssuePneumatic eBookPneumatics eBook

Why Use Pneumatics?

In manufacturing facilities, compressed air is so widely used that it is often regarded as the fourth utility after electricity, natural gas and water. But compared to electricity, compressed air is more expensive, so why is it so widely used to drive factory automation systems?

ApplicationApplication StoriesAutomation NotebookeBookIndustryIssue 34 - 2016Learning ResourcesManufacturingMaterial HandlingNotebook IssueOnline OnlyPackagingPLCPneumaticsProductProgrammable ControlSimple PLCUser Solutions

CLICK PLCs and Pneumatics Team Up for Success at Ridgeline Machine

Ridgeline Machine made extensive use of pneumatics when building a low-cost, small-footprint, portable traymaker to replace a manual process for one of their customers. Ridgeline Machine Design, LLC (RMD), founded in 2012, is primarily a packaging machinery producer, and the company’s owners have over 40 years experience designing and building custom machinery. RMD builds packaging…

Many control systems these days need a way to interact with the process or machine operator. Legacy systems might present a whole panel full of pushbuttons, lights and switches; the development of electronic HMI (Human Machine Interface) devices made operator control and monitoring operations much more flexible, presenting text, graphics and even video to help…

Well, don’t forget to check under the hood and see what the software has to offer. After all, hardware is only half of the equation. So, if you are considering the Productivity series of controllers you should be asking yourself, what is Productivity Suite and what does it offer? To help answer that, the following…

As you all probably know, field startups can be quite stressful. Did the equipment arrive on time and with all needed components? Has the site prep work been completed? Are all needed personnel and permits on site? Where are my plane tickets? Do I need to rent a car? What about hotel reservations? With all that…

You’ve probably seen some seemingly well-designed machines rendered unsafe because plant operators disabled safety switches. I know I’ve encountered such situations, and it’s our responsibility as engineers and designers to address this issue

AutomationDirect’s new eBook, “PLC Handbook: A Practical Guide to Programmable Logic Controllers” is now available as a free download. Designed as an easy-to-read guide for users new to PLCs, this eBook explains what a PLC is and its history. It also provides detailed information about what to look for when choosing a controller, with both…

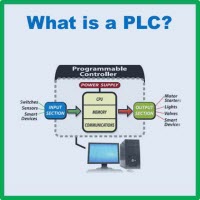

PLC Definition Programmable Logic Controllers (PLC) are often defined as miniature industrial computers that contain hardware and software used to perform control functions. More specifically, a PLC would be used for the automation of industrial electromechanical processes, such as control of machinery on factory assembly lines, amusement rides, or food processing. They are designed for multiple…

The PLC or Programmable Logic Controller has revolutionized the automation industry. Today PLCs can be found in everything from factory equipment to vending machines, but prior to New Year’s Day 1968 the programmable controller didn’t even exist. Instead what existed was a unique set of challenges that needed a solution. In order to understand the…