This resort site uses AutomationDirect VFDs to control waterpark systems, in the process adding the capability to manage and upgrade their own equipment. When the Triple R Camping Resort enhanced their facility to include a waterpark with interactive water features, they also needed to upgrade some behind-the-scenes elements, such as pumps, and the VFDs controlling…

Speed control is the most common VFD control mode, but many of today’s VFDs can also perform in torque control mode, which is needed for certain applications. Variable frequency drives (VFDs) let designers optimize equipment operating speeds, save energy, and even minimize mechanical wear—but VFDs can play another important role other than standard speed control….

Modern VFDs can now perform torque control for winding/unwinding and other applications, expanding options for equipment designers. Variable frequency drives (VFDs) are commonly used by automation systems to vary the speed of an AC electric motor, but there is another class of applications where torque control, regardless of speed, is the primary goal. Kevin Kakascik…

Modern processing plants need control panels built in accordance with specific design details. Chris Kregoski, product engineer for AutomationDirect, authored an article for the July 2022 Processing magazine titled Process Control Panel Design Basics. Here’s a summary, click on the link above for the full text. Processing plants typically incorporate extensive automation. The control panels…

Variable frequency drives are devices for starting, stopping and varying the speed of AC motors to improve control of equipment control and save energy. A variable frequency drive (VFD) is an electronic device used to vary the frequency of an AC voltage to adjust the speed of an AC motor. VFDs also provide start and…

Trickle-down technology has resulted in modern micro VFDs with capabilities formerly available only on top-tier models. Kevin Kakascik, Technical Marketing Engineer with AutomationDirect, wrote an article for the May/Jun 2022 issue of InTech titled Micro VFDs Gain Macro Features. This article points out the many advanced features now available even on micro VFDs, which help…

AutomationDirect washdown-rated VFDs help users add control functionality and realize cost savings even in challenging locations. Kevin McClelion, product engineer for AutomationDirect, wrote an article for the May 2022 issue of Processing titled Reducing complexity and cost with NEMA 4X VFDs. Here’s a summary, click on the link above for the full text. VFDs are…

ApplicationApplication StoriesIssue 49, 2023Machine ControlMotorsPLCProductProgrammable ControlVariable Speed Drives

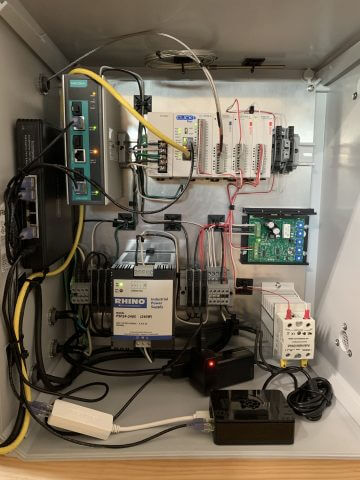

Opening the Automation Door

A home project to upgrade a garage door system with an AutomationDirect PLC, HMI, and VFD made the equipment run better, added many functional features, and provided extensive visibility and diagnostics. Industrial automation components have many applications outside the factory. Home and hobbyist projects can be a great way for learning how to execute larger…

Automation of a tabletop coffee roaster demonstrates how home automation projects can help users explore new technologies and develop their skills. Michael Hoffman, who works at Dragos and is a member of the SANS Technology Institute, wrote a success story for the October 2021 issue of Design World titled Brewing Up DIY Automation Solutions. Here’s…

New VFD features and technologies improve the control, safety, networking, and efficiency of motor control for a growing number of applications. Jeff Payne, product manager for the drives & motors group at AutomationDirect, wrote an article for the June 2021 issue of Plant Services titled Advanced Variable Frequency Drives are Working in More Applications. Here’s…