Designers can improve personnel safety by incorporating modern products and technologies, and by following a “design for safety” approach.

Marty Kronz at AutomationDirect wrote an article for the February 2023 issue of Applied Automation. Titled Addressing Electrical Safety Hazards, this article identifies how some newer products, sometimes in combination with automation, can increase the effectiveness of safety-related controls.

Each workplace establishes evolving policies, procedures, and program controls—collectively known as an electrical safety program (ESP)—to mitigate worker risk to an acceptable level. These are typically guided by well understood methodologies, such as the National Institute for Occupational Safety and Health Hierarchy of Controls.

While statistics indicate there have been a significant reduction in overall electrical injuries—more than 50% from 1992 to 2010—the number of non-fatal electrical injuries has flattened, which indicates that a point of equilibrium has been reached with respect to results (reference Workplace Electrical Injury & Fatality Statistics). Proper application of newer products and methodologies can improve this situation.

Electrical safety and lockout/tagout (LOTO) are governed by certain requirements. OSHA provides performance-based requirements (the “what”), while the NFPA explains prescriptive-based requirements (the “how”).

The strength of an electrical safety culture varies throughout commercial and industrial sectors and how proactive an organization is in general is often an indicator of how willing they are to adopt newer safety technology.

Trending technology for improving electrical safety

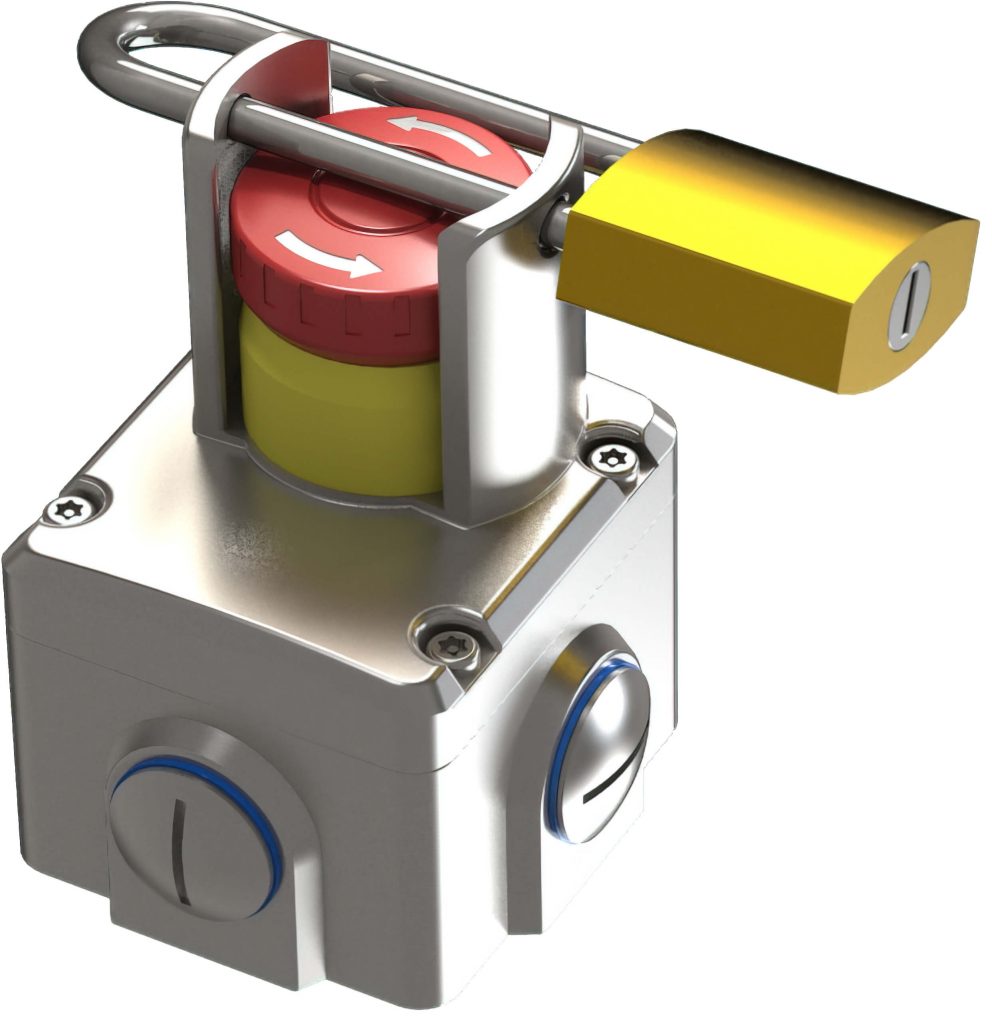

Access control

Basic access controls are simply procedures that all users must follow. However, there are many technology, networking, and automation techniques for proving worker credentials, confirming that personal protective equipment (PPE) is in place, and verifying whether equipment is in a safe/de-energized state. Devices include safety switches, interlocks, emergency stop buttons and cables, light curtains, and more.

Absence of voltage tester (AVT)

A more recent innovation, recognized in the 2018 NFPA 70E, is a new technology for verifying the absence of voltage within electrical equipment. Traditional methods called for equipment to be disconnected, and then tested by workers wearing proper PPE. A new category of absence of voltage testers (AVTs) as been developed, and they can be integrated with automation systems—much like other SIL3 safety-related devices—to automate safety, while improving overall system efficiency and performance.

A “design for safety” approach

Automobile backup cameras used to be an expensive and rare technology, but they are now commonplace and greatly improve user safety for operating cars. Designers and end users of industrial systems should be open to similar innovations and technologies, each of which can improve safety for personnel working with machinery and factory equipment.