Many years ago my father was working on a new shop behind his house. The insides were left for us to finish. We needed to build work benches, shelves and racks. To save money, he bought the longer 2×4 sized lumber and we’d cut it to whatever size was needed. This worked out great but the extra-long boards were unruly and a challenge to cut by one person because of the length. We didn’t have a nice chop saw setup that is so common now with the nice outriggers and side supports. We basically hade a saw with an old Black and Decker work bench. The kind with the clamp built into the table top.

Thinking Inside the Clamp

After many cuts using one hand on the saw and one hand trying to balance the board, I knew there had to be a better way. I started using the manual clamp that came with the saw but its range was pretty limited and it was better suited for thinner material than a 2×4. I remembered a pneumatic cylinder that I had grabbed out of a junk pile and thought that I might be able to make an automatic clamp with it. I found a piece of steel to mount the pneumatic cylinder to and then used a section of rod for the post. The rod had to be turned down by a friend on a lathe so it would fit in the clamp mount on the saw.

After many cuts using one hand on the saw and one hand trying to balance the board, I knew there had to be a better way. I started using the manual clamp that came with the saw but its range was pretty limited and it was better suited for thinner material than a 2×4. I remembered a pneumatic cylinder that I had grabbed out of a junk pile and thought that I might be able to make an automatic clamp with it. I found a piece of steel to mount the pneumatic cylinder to and then used a section of rod for the post. The rod had to be turned down by a friend on a lathe so it would fit in the clamp mount on the saw.

When I first used the pneumatic clamp on the saw I was amazed at how much force it had. I was able to place a 14 foot board under it and it would lift it and keep it perfectly clamped on the saw. When you’re trying to cut off 2 feet of a 14 foot board, that’s a big deal.

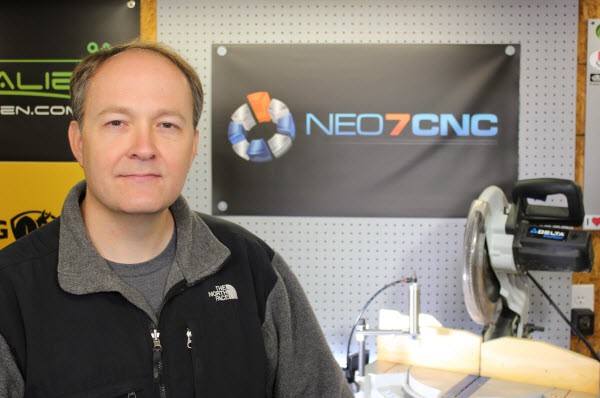

It was so useful for my dad and me that I wanted to revisit the project and share it on my website Neo7CNC.com and the Neo7CNC YouTube channel. I started documenting my very first DIY CNC machine build years ago and posted the videos on YouTube. With each new CNC machine or contraption I built, interest on the channel kept growing. I’ve continued to share my machines, experiences and information ever since. I really enjoy inspiring others to make things (CNC or not) and the interaction with viewers and sharing of knowledge is a huge bonus.

Since randomly finding a pneumatic cylinder doesn’t translate very well to my viewers, I wanted to find a source for most, if not all of the needed components for this build. AutomationDirect.com was my first choice. With a great selection, good prices and fast shipping, it was a no brainer. I’ve used them many times over the years. Not just for pneumatic parts but also for buttons, enclosures, sensors and much more. I was able to find just about everything from them. The only other items needed can be found at most local hardware stores.

To see how pneumatics was used in the saw clamp application or if you’re interested in DIY projects and CNC machines, please stop by the Neo7CNC.com website and YouTube channel.

To read more articles about programmable control, click here.