There are a lot of buzz words in the business world today, including flexibility, nimbleness, and agility just to name a few. Business experts recommend these attributes are essential for achieving and maintaining success. One of these terms, flexibility, is more than just a buzz word at Electri-Flex. To the people who are a part of this company, flexibility is a way of life.

Like many American companies, Electri-Flex was part of the post-World War II boom. Two entrepreneurs, Harold Kinander and Jim Doolin, envisioned a new and emerging product line of flexible metallic conduit. So in 1954, in a vacated chicken hatchery in Roselle, Illinois, they built two coiling machines which produced their new product called Type LT. Better known as Liquatite® this brand of flexible, liquid-tight conduit protects electrical wires from liquids, vapors, and other hazards. Within a year, their new product was already experiencing strong success in the marketplace.

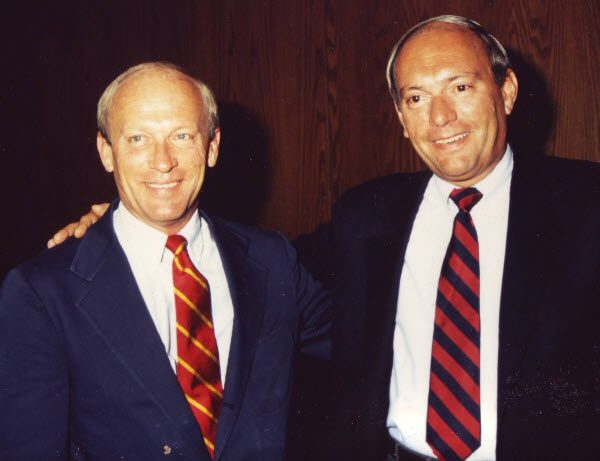

Liquatite® was so successful that in the 1960s, Harold Kinander’s two sons, West and Bruce joined the family business.

A Family Affair

Today, Electri-Flex is managed by third-generation family members of the Kinander family. But that’s in name only. Employees of Electri-Flex are the first to say that they’re all part of the family. A point proven by how long people have worked there. It’s not uncommon for Electri-Flex employees to have decades of experience. Throughout the organization there are employees with diverse talents, backgrounds, and levels of experience. The common denominator is they work together to grow with the company and a recognition that each person can make a special contribution.

Roy Hunn, General Manager at Electri-Flex, began his career there on the factory floor. “Working through the ranks means you can relate to the other employees no matter what job you have. Even the Kinander family worked on the factory floor in all of the departments when they started. It makes a difference when management is familiar with the entire operation,” said Hunn.

The structure of the Electri-Flex organization also allows for employee input throughout the organization. Ed Marinelli, President and Director of Sales, explains: “In this company everyone participates in the decision-making process and everyone shares in our quality goals. There are no special levels of employment where one person is more important to the success of our company.”

Including employees as part of the family was always the philosophy at Electri-Flex. That made it even more difficult when the company was struck by tragedy in the early 1990s. At that time, H.W. “West” Kinander, son of founder Harold and company President, died unexpectedly at age 50. Since then, the close-knit Electri-Flex family has pulled together in a way that would have made him proud. His son, daughter, and nephew are all an integral part of the company. They run it like many 21st Century companies with creative spark and innovation but with a nod to their beloved “West” whose memory is still ingrained in everything they do.

Dedication to Employees and Quality

Following the sudden death of West Kinander, Marinelli was named President and he helped the company move forward. In a company message issued shortly after stated: “Our commitment to the principles by which West Kinander lived won’t be forgotten. Life goes on. Business goes on. And, we will perpetuate those principles which put the ‘life’ in all our businesses – and industry.”

With that, the Electri-Flex family leaned on each other and overcame their losses to create a company that today provides the most diverse flexible electrical conduit line in the world with respect to available sizes, types, and colors.

To assure a high degree of quality control, Electri-Flex uses a vertically integrated manufacturing and production system with each step performed in-house by a team of experts. From machine operators and solderers to foremen, employees at every level are involved in the quality process. Testing begins when the raw materials are received at the facility and is maintained throughout the production process to when the finished flexible conduit is packaged and ready to ship. Along the way, a quality control inspector randomly collects samples of each product and tests it for tension strength, impact, crush, flexibility, flammability, and other various conditions. Testing is also performed by independent outside inspectors from U.L. and CSA.

Among the tens of millions of feet of conduit produced and sold each year, Electri-Flex is proud to claim a near-perfect record of zero defects. “Having each factory employee be part of the process is what makes the difference,” Marinelli explained. “Top quality is our trademark. Even the material handlers who stage the finished product for shipping are called upon to review the pallet loads one last time before it goes out the door.”

Expansion and Maintaining Tradition

Since the founding of Electri-Flex, the company has maintained its presence in Roselle, Illinois but now its headquarters is a far cry from the humble beginnings in the 2,100-square-foot renovated chicken hatchery. After moving in 1956 to a 4,000-square-foot abandoned woodworking shop down the street from the original location, the company moved again that same year to another facility in the same neighborhood but expanded into a 21,000-square-foot building. By 1968, the company had once again outgrown its facility. A new 80,000-square-foot building was constructed nearby. By 1978, the building was expanded to 120,000 square feet and, in 1989, an additional 35,000 square feet was added to accommodate Electri-Flex’s rapid growth.

Today, in addition to the Electri-Flex headquarters building there is a 64,000-square-foot distribution service center that completes the company’s campus — all within close proximity of its original location. “The addition was an important milestone in our company’s history as we continue to grow to meet our customers’ expectations,” said CEO Jason Kinander. “It also allowed all of the employees to stay close together on the same campus. It’s important to us to maintain that family feel throughout the organization.”

After 60 years and enormous growth, Electri-Flex continues to operate as a family business. Marinelli, who has seen the industry change in many ways over the years, emphasized that Electri-Flex is a company that has developed and succeeded through strong personal relationships based on loyalty and trust. “Many of our agreements in the early days were based on a simple handshake. Those types of long-standing relationships built on trust have helped us through some difficult times. We make a conscious effort every day to live up to the expectations of the people who do business with us.”

To read more articles about terminal blocks and wiring click here.