Circuit Protection

For most of us who work in the electrical design field, the question of circuit protection is omnipresent in our day-to-day efforts. There are a myriad of circuit protection technologies available that address phenomenon such as high voltage transients, inductive kick-back, capacitive coupling, high inrush currents and ground faults, just to name a few. However, the most common circuit protection devices guard against over-current situations. As most of us already know, over-current protection is typically achieved by incorporating either a fuse or a circuit breaker within the primary power feed. The biggest question that faces most electrical designers is which one of these devices to select for any given situation. More often than not, our selection of either fuses or circuit breakers is based on past experience and personal preference. In the context of any given industry, past experience is usually a good guide for this selection process. However, when changing projects or moving to a new job, what may be comfortable to you, may not be appropriate for the new application.

Circuit Breakers

Let’s face it, fuses and circuit breakers do pretty much the same thing; they protect the circuit from over-current situations. So what criteria do we use to select one or the other? The recurring argument that I have heard in favor of circuit breakers is that they are easier to reset after a failure situation has occurred. Although this is true, I’ve never really bought into this argument because, ideally, if the circuit is designed and used properly, the breaker should never trip. If you’re dealing with a breaker which trips on a regular basis, this should be taken as a clear indication that there is something seriously wrong with the circuit. In these situations, the convenience of resetting the breaker only serves to postpone the inevitable correction or re-design of the circuit. On the other side of the fence, the usual argument in favor of fuses is that they are dirt cheap. This particular argument does carry some merit, in that a properly designed circuit won’t blow fuses, and therefore, the one-time cost of a fuse and holder is considerably less expensive than its breaker counterpart. However, if a circuit blows fuses on a regular basis, the accumulated replacement costs associated with labor and down time can make a fuse set considerably more expensive over the long run. Additionally, if a fuse set is specified as an integral part of a power disconnect, then the cost is comparable to the equivalent circuit breaker arrangement.

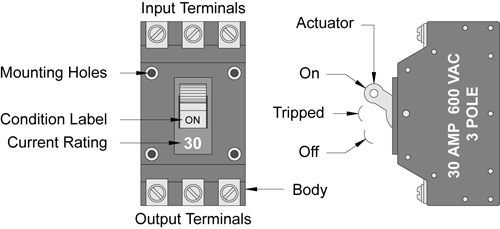

It should come as no surprise that both fuses and circuit breakers have their pros and cons. Circuit breakers certainly have some very favorable attributes. In most cases they can double as a power disconnect (see figure 1), which provides a great deal of convenience to any equipment that may require regular service. For these applications, breakers are even available with lock-out/tag-out facilities. Another attractive attribute of breakers is that they are inherently safe. The electrical connections are typically located behind a protective panel, which completely eliminates any possibility of electrocution. This feature is quite valuable, especially in those situations when non-electrical personnel are required to service the equipment. A third feature is that they usually provide a visual indicator when they have tripped. This feature can save a lot of diagnostic time if you’re the type of person who frequently forgets to check the fuses, and as it turns out, I’m one of those guys.

Fuses

For many professionals, fuse sets also have a number of desirable attributes. As mentioned previously, they are particularly inexpensive when compared to their breaker counterparts. They’re simple, quite easy to install and, in most cases, a fused disconnect, as shown in figure 2, is quickly attached to a utility panel with just a few bolts. Wires are usually connected with integral screw-type terminal blocks. In addition to their mechanical simplicity, the electrical flexibility that fuses provide can be a considerable asset, especially when working with unique circuits. In most new designs, the circuit’s current requirements can be closely estimated, however, various unanticipated situations may arise that might blow the fuse that was originally specified. In these cases, the selected fuse can be quickly changed for another unit that is better suited for the application. A good example of this is a machine that has a high power-up (surge) current. The original fuse specified may be quite adequate for the run current, but may blow each time the circuit is energized. A fuse set allows the technician to quickly correct the situation at the minimal cost of a few new fuses. The original fuses are simply replaced with time delay, or slow-blow, units carrying the same current rating and the problem is instantaneously corrected. A situation like this isn’t so easy to correct if you originally installed a |circuit breaker. In that case, the breaker must be removed and replaced with an entirely new unit with a rating appropriate to the conditions. The costs associated with a change like this are reflective of a new breaker and the labor to remove the old unit and replace it with the new one.

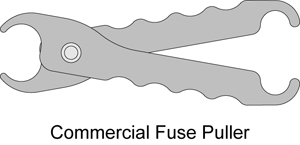

A significant disadvantage of fuse sets is their exposed electrical connections. In the case of larger, snap-in fuses, the socket clips are exposed and in close proximity to the opposite side(s) of the circuit. When the enclosure housing the fuse set is opened, these sockets expose the technician to a live circuit. Many power disconnects with integral fuse sets are specifically designed to eliminate this hazard when turned off. It is always recommended that a special set of insulated fuse pullers, as shown in figure 3, are used when changing larger fuses. However, in a pinch, the average technician will be under a lot of pressure to get the equipment operational. If they don’t have ready access to a fuse puller, they may resort to using more unsafe methods to dislodge a fuse and snap in a new one. There is simply no future in these improper practices, which will ultimately lead to an electrocution incident.

When it comes to flexibility within the design, fuses are typically considered a little friendlier than circuit breakers. Fuse sets are readily available as integral components in many power disconnects. These pre-packaged assemblies are particularly popular with both electricians and electrical designers. Despite the fact that circuit breakers are gaining popularity as power disconnects, fused units are still more prevelant throughout industry.

That’s not to say that breakers don’t offer the same level of flexibility. Circuit breaker disconnects have the distinct advantage of being about half the size of their fused counterpart, which means that they are easier to install on a densely populated utility panel. This, coupled with their inherent safety, means that more and more electrical designers are specifying circuit breaker disconnects for point-of-use applications.

Chances are the power distribution panels in homes and offices are equipped exclusively with circuit breakers. As it turns out, breakers are particularly suited to power distribution applications. In these cases the branch circuits may have a wide variation of loads connected to them at any given time. Therefore, statistically speaking, it’s possible, and even probable, that a branch circuit will be periodically exposed to an overload condition that will trip the breaker. In these situations, the simplicity of a circuit breaker becomes apparent. By simply addressing the over-current situation and resetting the breaker, the branch circuit is back on-line. In addition, circuit breakers provide a much more compact and logical layout when setting up the power distribution center in most industrial environments.

The overwhelming availability of both fuses and circuit breakers on the market is a clear indication that neither represents a significant advantage in all circumstances. For any given project, the selection to use either a circuit breaker or a fuse set will ultimately remain the decision of the electrical designer. In most instances, considerations such as purchase price, manufacturing costs, service requirements and space constraints will play a larger role in the selection process than the actual electrical characteristics of the circuit. It seems the best advice that anyone could offer for this topic is to thoroughly educate yourself in both technologies and practice diligence when applying either.

By Brian S. Elliott

Brian S. Elliott Bio

Brian S. Elliott is the Chief of Engineering for Air Options, Inc. in Houston, Texas. He is the author of the Compressed Air Operations Manual and Electromechanical Devices & Components, both published by the McGraw Hill Book Co. He is a regular contributor to several industrial publications, including the Automation NOTEBOOK.

Originally Published: March 1, 2009