Manufacturers are finding they can rapidly and flexibly adapt to changing production needs by engaging in-house personnel to deploy automation solutions.

Automation is essential for improving productivity and quality, but many manufacturers serve markets where production volumes and product options vary drastically. As a senior maintenance and integration supervisor at Keytronic, Jose Luis Rodriguez Persona is familiar with the challenges. He wrote a success story article for Machine Design November 2022 titled Rapid Automation Deployment Requires Cooperation, describing how he and his team progressively deploy commercial off-the-shelf (COTS) automation products from AutomationDirect to optimize production and save money.

Change is a Constant

For over 50 years, Keytronic has manufactured products for a wide range of customers and markets. To do so, their manufacturing sites use machines and processes so they can perform plastic injection molding, printed circuit board assembly, metal fabrication, and more. Product details and demands vary, often rapidly, and a production run might be as short as a few hundred pieces over 30 minutes, or as long as many weeks. Manufacturing equipment can be years-old legacy systems or brand-new. Automation solutions must integrate all the machines, provide multi-language visualization, and support quick changeovers.

Adaptability Successes

To the greatest extent possible, the Keytronic team works to keep these projects in-house using personnel intimately familiar with the processes and customers. For best efficiency, the team needs to choose hardware and software from a complete portfolio offering readily available parts that are easy to configure, are backed by solid documentation and support, deliver top reliability, and provide a good price/performance ratio. With years of experience under their belts, the team has standardized on AutomationDirect.

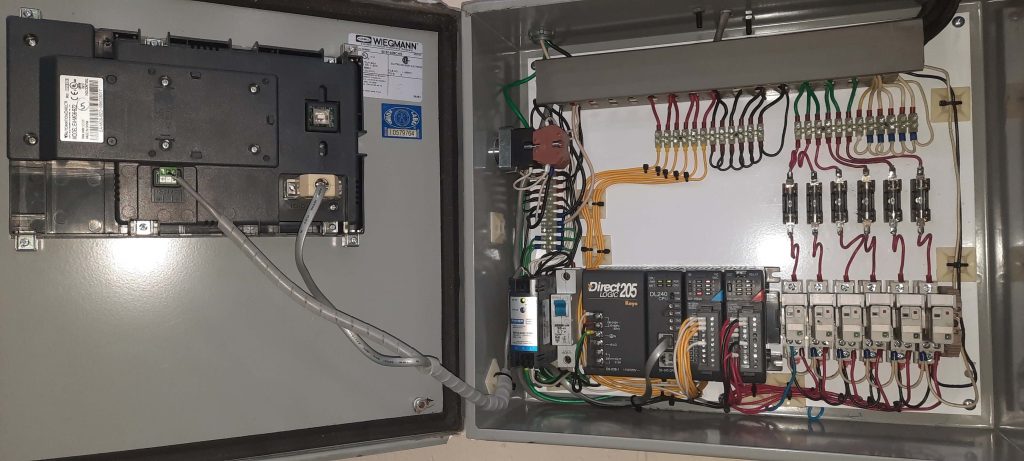

Early projects were automation retrofits of PLCs and HMIs used for a resin loading system and blow molder. AutomationDirect DirectLogic PLCs, C-more HMIs, and various electrical components were used. Because the work was performed in-house, there was ample opportunity for operators to provide input as control logic was developed, and extensive help message and multi-language displays were created.

Automation with Agility

In practice, the team has found AutomationDirect products to be straightforward and easy to use, with exceptional reliability and positive results enabling them to take on ever more ambitious projects.

Comprehensive suppliers like AutomationDirect make it easier for manufacturers to control their own destiny by performing some or much of the work themselves, exactly meeting the needs of internal operators and external customers.

By standardizing on AutomationDirect, Keytronic is consistently improving their operations with new technologies and capabilities, while controlling costs.

All figures courtesy of Keytronic