I remember years ago walking into a production facility and being intrigued by the processes taking place in each section of the production line. It was so interesting to see how things were shaped, packed, filled and more. Every step or section of the production line had a specific purpose that needed to be completed before the next step, until the end product was finished, tested and packaged.

It was always fascinating to discover how a product was made, the machinery used, the controls and how it all tied together. Every station had its own control panel, machinery, computers, operator panel and other devices. The production areas were filled with the smell of the product or chemicals used for the process, the blinking lights of the control panels, and the sounds of motors, machinery and alarms.

One of the things that always stood out, no matter where you were standing on the production line, was these posts with steady or flashing green, amber, red and other colored lights. I could scan most and sometimes all of the production line floor and see them lit up or blinking in different colors. Red flashing lights indicating there was trouble on that machine. Green lights indicating the machine was running and online. Amber lights indicating the machine was running properly but in standby or paused mode. Each facility had their own way of using the lights and colors to indicate a status or condition of the process. Through the years I heard them called light beacons, warning lights, light tower, signal lights, luz de señal (OK, so that one was in Spanish), and other names.

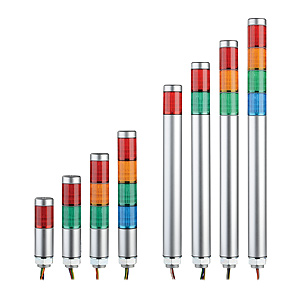

All these are valid names but today they are best known as Stack Lights, mainly because of the way the lights are stacked over each other, or Signal Towers because they are commonly mounted high over a machine to signal current machine conditions. The basic stack light has remained pretty much the same in the sense of being a column of lights stacked over each other. However, most devices available today offer rugged construction, efficient lighting, and corrosion resistance, and are easy to tailor with configurable color and sound pattern options. So, in a world where easy installation, configuration, and maintenance, as well as cost, durability and flexibility are important, Patlite stack lights stand above the rest as an example of what a modern, top-of-the-line stack light should be like.

AutomationDirect proudly offers these high-quality and ruggedly built stack lights made by Patlite at the best prices in the industry, available in model sizes ranging from 25mm to 70mm and pre-assembled models with one to five-tier LED lights (depending on the series/model). The high-intensity LED illumination and prism-cut lens design provide enhanced visibility from any direction, making them ideal for practically any application. For the ME, MES, MP, MPS and LS7 series the color of the light may be provided by the LED bulb, allowing the lens to be clear, thus eliminating the confusion of thinking a light is on when sunshine or another light source shines on the lens. Construction material options for these stack lights include aluminum, ABS resin, and polycarbonate, making them ideal for corrosive environments, or areas where impact, shock or heat resistance matter. In addition, the LS7 series includes models that are IP69K rated for environments where high-pressure washdowns are required. Options and accessories for these stack lights include configurable audible alarms, additional LED modules, caps, screws, mounting brackets and adapters, O-rings, pedestals, and extension poles.

There are four unique Stack Light series to select from:

25mm ME (long body)/MES (short body) Super Slim Series

25mm ME (long body)/MES (short body) Super Slim Series

- 1 to 4 LED tiers

- Aluminum body, excellent for corrosive environments

- Small size makes it ideal for tight spaces

- Polycarbonate lens for impact, heat resistance, and increased light transmission

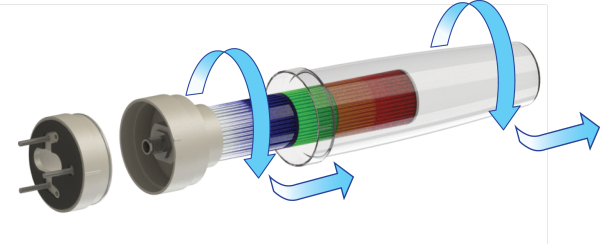

- Wiring-free interchangeable modules

- IP42-rated (NPN models); IP65-rated (PNP models)

- Designed for direct mounting

- Accessories available

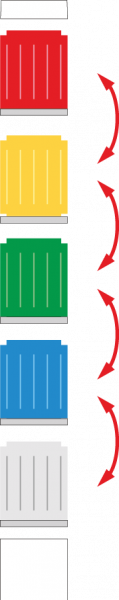

Interchangeable LED Modules

Color sequence is changeable by adding or removing up to 5 color modules even after installation.

NOTE: LED modules of the same color within a signal tower will light up simultaneously.

Wiring does not change

The LED module colors correspond to the wiring, so re-wiring is not necessary.

30mm MP (long body)/MPS (short body) Series

30mm MP (long body)/MPS (short body) Series

- to 4 LED tiers

- ABS resin, excellent for impact and heat resistance

- Optional alarm buzzer model

- AS resin prism lens for superior weather resistance and increased light transmission

- Wiring-free interchangeable modules

- IP65-rated

- Designed for direct mounting

40mm LCE Series

40mm LCE Series

- 2, 3 or 4 LED tiers

- ABS resin, excellent for impact and heat resistance

- Two built-in alarms (FB models) with selectable sound patterns

- AS resin prism lens for superior weather resistance and increased light transmission and with dual reflection system for enhanced light diffusion

- Wiring-free interchangeable modules

- IP54 (pole mounted); IP65 and NEMA 4, 4X and 13 direct mounted)

- Available for direct or pole mount

70mm LS7 Series

70mm LS7 Series

- 3 and 5 LED tiers

- Polycarbonate body, excellent for shock resistance

- Smooth surface body with no visible screws or metal components reduces adhesion of water and dust

- Alarm buzzer models available

- Inner lens LED emits a more efficient light

- M12 connector quick-disconnect

- Wiring-free interchangeable modules

- IP65 rated (Buzzer models are IP54 rated and WC9 models are IP69K rated suitable for high pressure and high temperature washdown environments); NEMA 4, 4X and 13 rating for -W and -FBW models