Recent additions to the National Electrical Code (NEC) mandate surge protection for safety interlock circuits to protect operators and machinery.

Brent Purdy PE is the Product Manager for Power & Circuit Protection products at AutomationDirect. Brent authored an article for the June 2019 issue of Automation.com titled Regulations Require Surge Protection for Safety Circuits. Here’s a summary, click on the link above for the full text.

Safety considerations are crucial for industrial machinery design, and in recent years the bar has been raised many times to provide improved protection for workers. For example, emergency stop (e-stop) and safety interlock circuits have long been part of the applicable codes. Now, new codes recognize that safety interlock circuits also need surge protection.

By the Book

Original equipment manufacturer (OEM) machine builders are already impacted by many codes and standards. A new item was added to the 2017 revision of the National Fire Protection Association (NFPA) 70, also known as the National Electrical Code (NEC), section 670.6. It states, “industrial machinery with safety interlock circuits shall have surge protection installed.” Brent describes the history.

The reason behind this is that over a quarter of facility managers surveyed in 2013-2014 indicated their sites had experienced damage to safety interlock circuits attributable to electrical surge events. Since surge suppression is a well-understood and cost-effective technology, it only makes sense to apply it for critical applications.

Regardless of code requirements, incorporating surge protection is always a best practice since any location can be subject to an electrical surge.

Why Interlock Circuits are Susceptible

Electrical surges, also known as transient over-voltages or spikes, are more likely to damage delicate solid-state electronic circuits than simple electro-mechanical devices like limit switches and relays. However, safety circuits are vulnerable because they now often incorporate electronics, explains Brent:

There are many safety interlock device options now available, such as coded non-contact switches and light curtains, that incorporate electronic elements. These advanced components can offer enhanced safety by being difficult to defeat and by sensing operator presence before a person approaches a hazardous area.

Safety interlocks circuits are not the only systems impacted by Code changes. The 2014 NEC revision addressed emergency power systems for power distribution switchboards and panelboards, and the for 2017 NEC 695.15 extends this to fire pump controllers.

Surge Protective Devices in Action

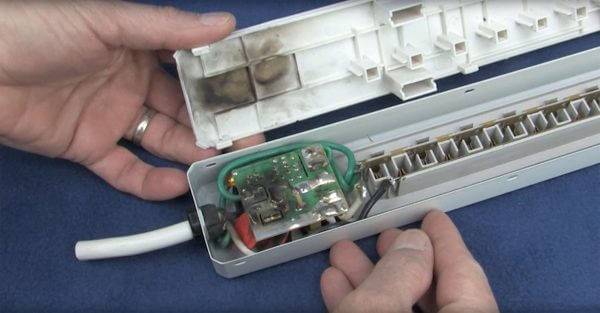

The primary method of protecting equipment from electrical surges is by connecting properly sized and rated surge protective devices (SPDs) into the power lines supplying the target circuits. Surge protection devices should be compliant with Underwriter’s Laboratories (UL) 1449 standard for surge protective devices, especially if they are to be installed in UL 508A listed industrial control panels. The way these devices usually work, says Brent, is to conduct and redirect surge current once a threshold voltage is exceeded.

Industrial SPDs generally work by incorporating metal oxide varistors (MOVs) sized and configured to shunt a transient overvoltage spike to another conductor or ground so the electrical current is redirected away from protected components, thereby protecting them. Generally SPDs are connected in parallel with the circuit. SPDs are passive devices until a transient occurs then the SPD “takes” action shunting the energy safely away via the appropriate mode of protection, such as line-to-ground and line-to-neutral.

How to Comply

SPDs are available in a few form factors, such as a terminal block or a small enclosure with leads. Here are some key features to look for:

- ANSI/UL Type 1 or 2 SPD protection

- Compact size

- NEMA 4X enclosure for indoor or outdoor use

- 0.75-inch NPT threaded nipple for mounting directly to conduit fittings or inside an industrial control panel using a mounting bracket.

- LED status indicator light

Prudent designers and engineers should specify and install surge protection on equipment such as:

- Fire Pumps

- Packaging machines

- Conveyor lines

- Metal working/forming equipment

- Industrial robots

- Woodworking machinery

Compliance Elevates Safety

Designers of industrial machinery and automated equipment will be required to comply with 2017 NEC 670.6 moving forward. This means installation of surge suppression for safety interlock circuits on all new machines and systems, with consideration for adding these devices to all forms of industrial equipment. Fortunately, many products are available. According to Brent, better protection is an ongoing trend.

These new requirements are only the beginning of the regulatory wave of interest in surge protection. Like ground fault protection and arc fault protection in residential homes, it is likely that future regulations will look at surge protection in other areas.

Click to read more articles related to safety.