Just like electricity, natural gas and water, compressed air is often a required utility in manufacturing facilities. Although compressed air is a bit more expensive compared to electricity for industrial machinery applications, it has other advantages and is thus frequently used to drive mechanical motion.

Simplicity of Pneumatics

Chip McDaniel, Technical Marketing Engineer at AutomationDirect, wrote an article titled Keep it Simple with Pneumatics, which ran in the August 2017 issue of Industrial Equipment News. McDaniel focuses on why pneumatics is used to power linear motion, along with some of the basic pneumatic hardware required for these types of applications.

Pneumatic Advantages

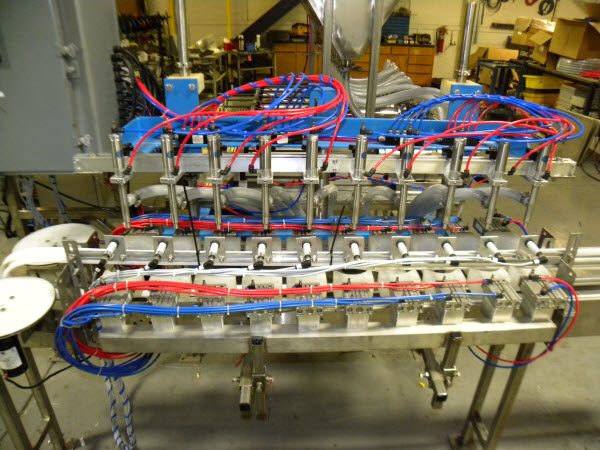

McDaniel discuses some of the many advantages of using pneumatics including simplicity, cost and reliability. This conveyor-based packaging machine, build by Riada Equipment with AutomationDirect control and pneumatic hardware is a great example.

“Pneumatic systems are easier to design and use than their electrical counterparts in many applications because pneumatic cylinders and actuators provide a quick path to linear motion. These devices also provide significant force in a small space for clamping, positioning or holding a part.”

These pneumatic systems, using cylinders and actuators, provide repeatable end-of-stroke position using shocks, cushions or hard stops—making them well suited for use in a variety of industrial applications.

“In a variety of automated machines, pneumatic power transmission is often the best way to grip, lift, press, shift or stack products. With the addition of some passive or adaptive control—as simple as a regulator in many cases—applications such as tensioning, crimping, cutting and labeling are feasible and practical.”

A Variety of Pneumatic Hardware

McDaniel’s article provided a Table with a list of common components to prep, distribute, control, actuate and monitor pneumatically operated machines. The Table is shown below, followed by discussion of the listed items.

Table, Common Pneumatic Components Used in Machine Automation

- Air preparation system

- Pressure switches

- Control valves and manifolds

- Air cylinders and actuators

- Cylinder position sensors

- Tubing and hoses

- Push-to-connect fittings

- Specialty components and accessories

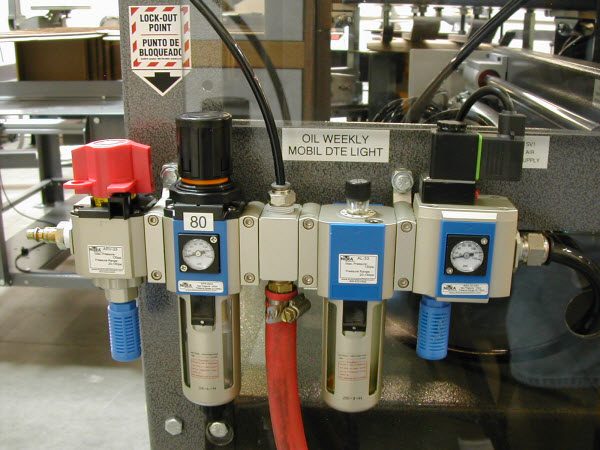

Plant air is dropped to the machine air preparation unit, which should be included on all machines using pneumatics. The unit provides a manual shut-off/lock-out valve, combination filter/regulator and soft-start valve. The electrically operated soft-start valve is an important safety item as it is used to exhaust air during an emergency stop and other hardwired safety events.

McDaniel talked about some of the other common pneumatic hardware and some good design practices:

“It’s good design practice to monitor air pressure at the machine using a pressure switch with local indication. Although rarely needed, a lubricator is sometimes included in an air prep system. A variety of control valves such as manual, air pilot and solenoid operated feed air to power transmission devices such as cylinders and actuators. These devices should be monitored by position sensors at the end of travel.

Many different types of tubing and hoses and related push-to-connect fittings are available to connect all the pneumatic devices together. Other specialty components and accessories such as flow control, quick exhaust valves, check valves, gauges and inline pressure regulators provide simple ways to adjust and control the operating characteristics of the pneumatic system.”

All these pneumatic devices are available from AutomationDirect.com. They can be easily specified through the online store, or you can call AutomationDirect’s award-winning tech support to help you specify a cost-effective and reliable pneumatic solution for your machine automation application.

Read more articles about the simplicity of pneumatics.