The wonderful world of pneumatics is one you’ll want to explore for all of your linear power transmission projects. Although alternatives such as hydraulics and electric work better in certain machine automation applications, pneumatics is often the preferred solution. This is particularly the case when lower upfront costs and reduced long-term maintenance are important, along with simplicity and reliability. That’s the good news.

The not so good news is that pneumatics can be somewhat complex and confusing due to the many options, products and accessories. But not to worry, AutomationDirect is here to help with expert application advice from our team of engineers and specialists delivered via a phone call, by perusing our award-winning web site, or by watching one of our entertaining and informative videos

Once you decide what pneumatic components you need to automate the linear motion in your machine automation application, rest assured you can find all the required parts and pieces on our web site or in our catalog. There’s no need to work with multiple suppliers and risk whether purchased products will work together. Instead, you can come to us for all your pneumatic project needs from design to procurement to support, and all at no charge!

Our Pneumatic eBook is a great place to start for both new and more advanced users. This recently updated eBook (Coming Soon!) provides a comprehensive guide to the use of pneumatics for machine automation and other applications. Twelve chapters encompassing 60 plus pages provide not only a solid introduction to pneumatics, but also the details required for design, selection and application.

From design basics to available products to systems in action—this practical guide helps inform new and experienced users alike. Handy diagrams, images and tables assists users in selecting the best pneumatics products and following preferred design practices, leading to successful installations.

Check out the content below for even more pneumatic info, and feel free to give us a call with any questions!

Pneumatic System Design Considerations

Pneumatic Cylinder Design Factors

This eBook is for users who wish to advance their pneumatic knowledge. It covers a wide range of topics such as circuit symbols, component capability, integrating pneumatics with controls as well as improving pneumatic efficiency

Calculating Air Consumption

Check out this handy air consumption calculator that will tell you the SCFM that will be consumed. Enter your bore size, stroke length, cycles per minute and inlet pressure to get started.

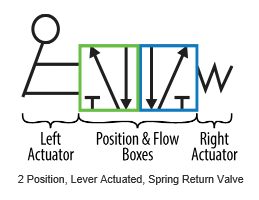

Understanding Circuit Symbols

Directional air control valves are the building blocks of pneumatic control.

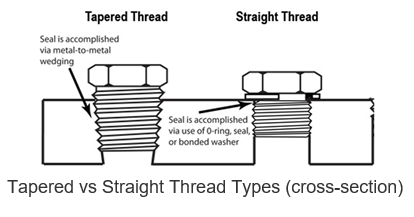

Determining Thread Sizes

Threaded fittings are used extensively to facilitate the connection of components, tubing and hose that make up all pneumatic systems. The different thread types and sizes can be confusing.