Improved technologies and expanded user demands have pushed the evolution of industrial automation technologies, and PLCs continue to advance and meet these needs.

Almost a decade ago, Jeff Payne at AutomationDirect wrote a Control Engineering article titled Future of the PLC . At that time, PLC technology was already 50 years mature but still a foundation industrial automation technology. With another 10 years of development behind us, he revisits the topic with his Control Engineering May/June 2024 article titled Back to the Future of the PLC.

Accelerating Technology, Steadfast Fundamentals

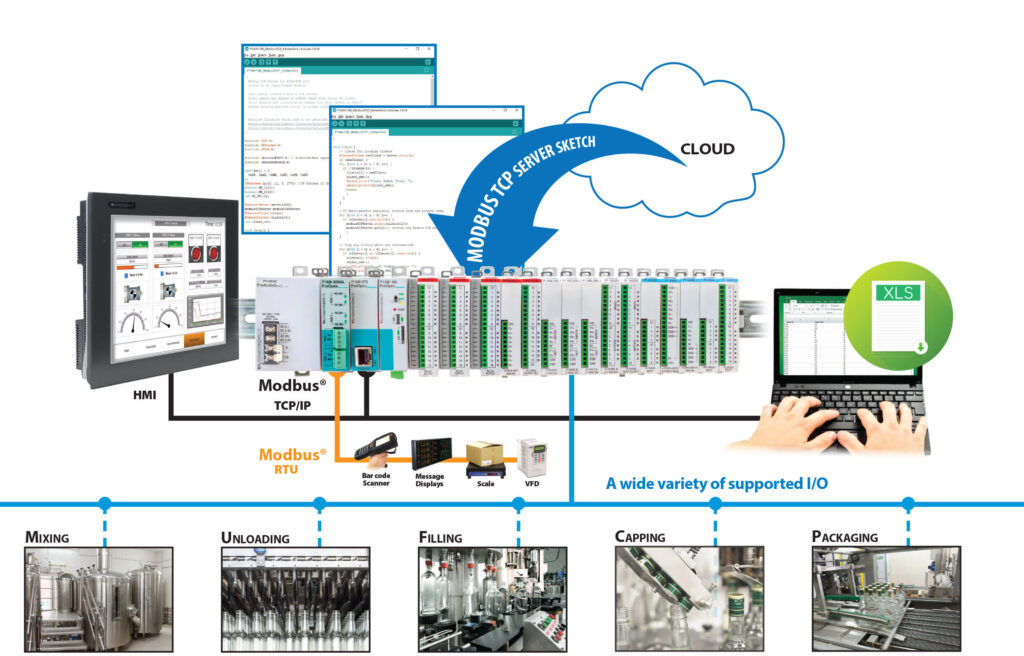

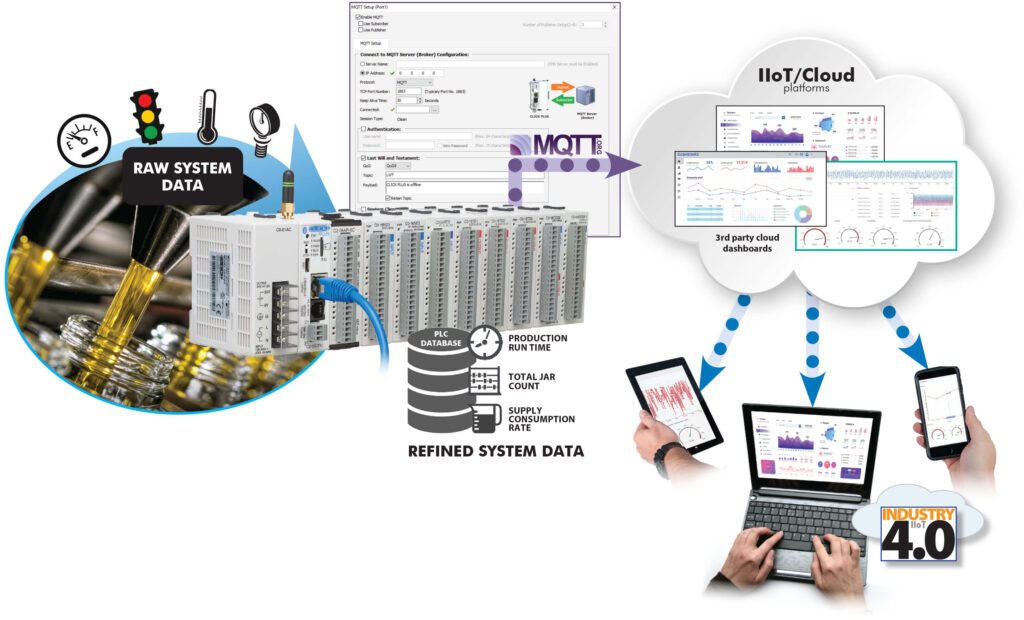

Advances in computing hardware, software, intelligent measurement, cloud accessibility, and communications connectivity have greatly expanded what is possible in the factory floor operational technology (OT) realm, and these advances have improved integration possibilities with higher level information technology (IT) resources. The last decade has seen a great emphasis on implementing industrial internet of things (IIoT) technologies for all types of applications.

However, the core mission of PLCs is still to deliver deterministic control and reliable monitoring in challenging environments. PLCs have largely incorporated size, cost, and performance improvements, and some newer variations such as programmable automation controller (PAC) and edge controller have arrived. Open-source platforms and programming languages provide even more options, but users are less concerned with nomenclature and more interested in capabilities.

Increasing Flexibility, Maintaining Reliability

For industrial automation, flexibility cannot come at the expense of reliability. Users want more features, but combined with guaranteed performance and maximum ease-of-use. With that in mind, here are a few thoughts about what the coming decade holds for industrial automation:

- Users will consider all types of underlying hardware platforms and operating systems, if proven real-time control, flexible programming languages, essential motion control, and other needed features are delivered.

- Users desire automation platforms offered and backed by trusted and experienced suppliers.

- Automation platforms may be called PLCs, or PACs, or edge controllers, or something else; nomenclature is less important than performance.

- Bridging OT to IT is increasingly important because automation platforms need to support the fieldbuses, networking media, communications protocols, and programmability to support these efforts.

- While there used to be a large distinction between the capabilities of smaller and larger controllers, users now want advanced options available even in very basic and low-cost automation platforms.

- Robotics has progressed from a specialty into the single largest growth area for industrial automation. Modern automation platforms need the capability and connectivity to seamlessly integrate robotics and supporting technology, like vision systems.

- While PLC-level devices are not currently ideal for “runtime” applications of artificial intelligence (AI) and machine learning (ML), they are well placed to act as a field interface supporting higher-level AI/ML resources.

- Generative AI (Gen-AI) is poised to play a larger role, supporting users from a code creation standpoint.

PLCs Remain a Part of the Automation Platform Picture

PLCs will continue to evolve based on available technologies and user demand, just as they have for the past five decades.

Over the next decade, PLCs as we know them will certainly not go away, even if they are referred to as PACs, or edge controllers, or automation platforms, or something else. There will be no single controller technology that can fulfill all roles at all price points.

AutomationDirect has maintained a focus on providing the products and solutions end users need to automate their equipment and projects and will continue to do so. Visit our website at AutomationDirect.com to see our portfolio of current and new PLC products, ready to support you into the next decade and beyond.