As robot capabilities expand and costs drop, machine builders and system integrators are creating tightly integrated robot-automation solutions for production lines.

Many dismiss industrial robots as too costly, complex and inflexible. It’s true that for many years robots have been an expensive technology used primarily for stacking parts and welding. However, robots are playing an increasing role in manufacturing as technological advances enable them to perform more functions with simpler implementation. Moreover, combining robots with machines creates highly automated production lines that help users control costs and streamline operations.

Even as robots become more advanced, their cost is decreasing, spurring increased use. The Robotic Industries Association (www.robotics.org) reports a 20 percent increase in units sold in 2012 over 2011 sales, attributable in part to lower prices. For example, ST Robotics (www.strobotics.com) recently announced that its Tandem R125, with two five-axis vertically articulated robot arms, will sell for $20,000.

Robots on Production Lines

As robots become easier to use and integrate with other systems, many machine builders view them as simply another tool, much like a press or an injection molder. One use is in highly automated production lines where robots and machines are tightly integrated, thus eliminating the need for intermediate material handling tasks.

For example, Intelligrated (www.intelligrated.com), which builds material handling solutions in Cincinnati, uses robots to automate production lines. The company utilizes robots for simple, end-of-line palletizing cells, complex multi-line palletizing systems, case packing, depalletizing systems and other material handling applications.

In the Control Design cover story “Robots and Machines Become Partners in Motion,” Earl Wohlrab, manager of robotic integration at Intelligrated in Cincinnati explains, “Robots become faster and more cost-effective every day. This allows us to move robotics into places that were previously unthinkable.”

Concept Systems (www.conceptsystemsinc.com) in Albany, Oregon, also contributed to the Control Design cover story. This system integrator uses robots and vision systems to streamline machine design. Michael Gurney, co-CEO at Concept Systems, says robots eliminate the need for mechanical guides and fixtures. This reduces product changeover times, simplifies the parts-feed process and eliminates many mechanical components.

Delkor Systems (www.delkorsystems.com) in St. Paul, Minnesota explains in the cover story how robots are improving its packaging equipment (Image 1). “We use robots primarily to load product into trays, cartons or cases. They provide reliable, quality operation and speed, plus allow flexibility to accommodate customer-specific requirements,” says Adam Koller, director of engineering at Delkor. He adds, “The robots pick random product off a conveyor using cameras, or pick pre-collated product from a collation belt.”

Image 1: A Delkor robotic loader, designed for high-speed carton-top loading, is used for the latest upstream equipment, such as the horizontal flow wrappers.(Courtesy of Control Design’s cover story “Robots and Machines Become Partners in Motion”).

Image 1: A Delkor robotic loader, designed for high-speed carton-top loading, is used for the latest upstream equipment, such as the horizontal flow wrappers.(Courtesy of Control Design’s cover story “Robots and Machines Become Partners in Motion”).

Koller says the lines are built in a modular fashion and consist of a carton-forming machine running anywhere from 30 to 200 cartons per minute, a product collation section, a robotic loading cell, and a carton-closing machine. “Conveyors connect the modules to one another,” he adds.

Furthermore, according to the cover story, many robot vendors are customizing robots for machine builders. Tom Hasse, industrial automation and process control consultant at Frost & Sullivan in Mountain View, Calif., says “For special applications that require complex movements and/or interactions with other robots, robot manufacturers will provide a work-cell solution that is more cost-effective for the machine builder.”

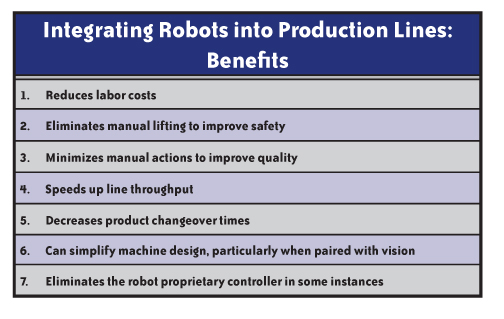

Table 1: Integrating Robots into Production Lines; Benefits

A Turnkey Offering

Many machine builders and integrators install, commission and service entire integrated machine/robot production lines. These turnkey systems create a single point of responsibility that makes it easier for customers to maintain their production lines.

In the cover story, Koller says this approach, “benefits our customers because we include full line support for the sales and application engineering, service, aftermarket support, system-wide safety risk assessment, and a performance guarantee covering overall operational efficiency.”

Staff reductions and the difficulty in finding qualified engineering personnel encourage a turnkey solution because it reduces the manpower needed for a production line. The upfront costs of a turnkey system are higher, but the benefits, including the transfer of risk from the end user to the machine builder, are often substantial enough to make it the more affordable solution in the long run.

Robot Control Options

In general, there are two approaches for robot control: use the robot vendor’s controller, or automate the robot with a separate controller. In the second approach, the robot integrator uses programmable logic controllers (PLCs), programmable automation controllers (PACs) or industrial computers to control the robots.

Many machine builders use proprietary control systems from the robot vendor, but others find a general-purpose control system is a better fit for an integrated automation line. There are advantages to both approaches.

The technical and ease-of-use advantages of using robot proprietary control systems often benefit machine builders. Programming is supplied by the robot manufacturer, eliminating the need to write software and shortening development time.

In the cover story, Terry Zarnowski, director of sales and marketing at Schneider Packaging Equipment, explains that using proprietary control, “provides a tight, high-speed, closed-loop control that’s needed to ensure the speed and accuracy of the arm and the tooling.”

The decision to use proprietary control often rests on the type of robot used. In the cover story, Marvin Tisdale, manager of automotive and mobile solutions for Lenze Americas explains, “Proprietary systems for six-axis robot control are the rule, not the exception. Delta or SCARA-type robots requiring only three or four axes are more likely candidates for general-purpose controls.”

PLC-based Control

In many instances, there are distinct advantages to the machine builder or integrator programming the robots themselves. Today, more robotic systems are being controlled and monitored by general-purpose automation systems. Notably, the multicore processors in industrial PCs expand the performance of PC-based controls to accommodate the bundling of many complex functions onto one powerful device. Common PC-based programming environments and industrial Ethernet also have made programming easier.

Arc Specialties and Concept Systems have both developed their own robot controls using a general-purpose motion control system. Others prefer to develop their own PLC-based control. For example, Intelligrated uses PLCs to control some of the robots provided with its integrated material handling systems.

In the cover story, Wohlrab says PLCs are gaining traction in the material-handling business. Wohlrab adds, “I envision a future where a single PLC will control small packaging lines that include several robots.”

A PLC programmed by Intelligrated controls the company’s Alvey robotic palletizer (Image 2). The company states the new control system improves line integration, response time and overall productivity while reducing operator and maintenance training

Image 2: Controlled by a PLC programmed by Intelligrated, the Alvey robot is an example of a complete integrated robotic material handling system. (Courtesy of Control Design’s article “Robots and Machines Become Partners in Motion”).

Image 2: Controlled by a PLC programmed by Intelligrated, the Alvey robot is an example of a complete integrated robotic material handling system. (Courtesy of Control Design’s article “Robots and Machines Become Partners in Motion”).

Wohlrab also believes PLC-based robotic controls are a good alternative to the traditional proprietary robot controller. In the cover story, he says “These solutions enable our customers to deploy new Alvey robotic palletizing solutions while maintaining a standard and familiar control platform. With minimal training, plant floor personnel can support these robotic applications without becoming robotic experts.”

Tighter Integration with Automation Systems

As robots become more multi-purpose and less expensive, there will be increased robot use and tighter integration with general-purpose automation systems. As machine builders seek to increase performance and efficiency, automating robots with the same controller that automates other machine and production line functions will become more prevalent.

End users will benefit from using general-purpose controllers to automate robots as integrating robots with a standard control system helps minimize integration issues. In terms of the automation system, end users will need just a single point of contact to call for troubleshooting and support.

One of the common future predictions for robot integration in automation systems sees standard technologies such as Ethernet being used to connect all equipment in a manufacturing line. There will be embedded robot control, with the controller being a standard PLC or PAC. This will create integrated control solutions with all configuration, programming, kinematics, troubleshooting and operations performed within a single control platform.

Regardless of how robots are controlled in the future, there is one certainty: Robots will become more and more integrated into production lines because of decreasing costs, improved flexibility and simpler implementation.

By Christine Lesher

controlspr.com

For more articles about programmable control, click here.

Originally Posted: March 1, 2013