Since the terrorist attacks of September 11, 2001, the need for perimeter security of potentially threatened facilities has increased dramatically. To accomplish this, several facilities around the globe have been installing devices called anti-terrorist barriers, used as added protection against invasion of potentially dangerous vehicles. Domestically, these anti-terrorist devices can be found at Federal Reserve banks, nuclear power plants, refineries, military bases, and municipal utilities. International installations include US Embassies and consulates. The US Department of State sets strict standards for these barriers, with only a handful of manufacturers meeting the requirements. Among these strict requirements, the highest criterion for protection against attack by a vehicle is the ability to stop a 15,000 pound truck, traveling at 50 mph, within a 1 meter distance, which is barely over 3 feet.

Intertex Barriers, Inc.

Intertex Barriers, Inc. of Valencia, California is one of the manufacturers that have met these strict requirements. Intertex Barriers designs and installs deployable road blocking barricades that can stop a speeding truck, laden with explosives, from being delivered into the front lobby of a building. This is accomplished using a control system heavily comprised of products offered by AutomationDirect.

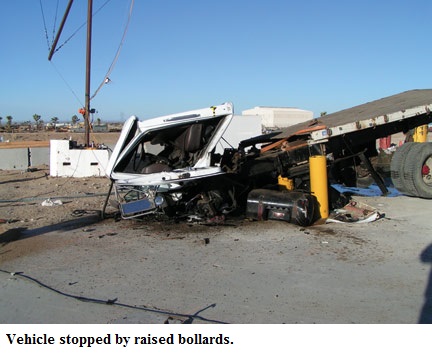

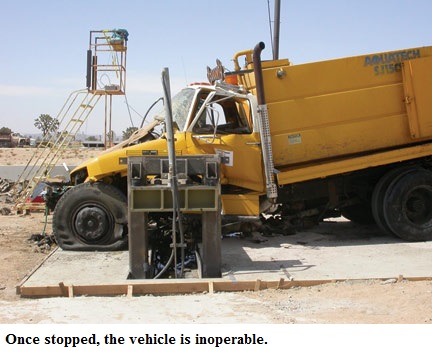

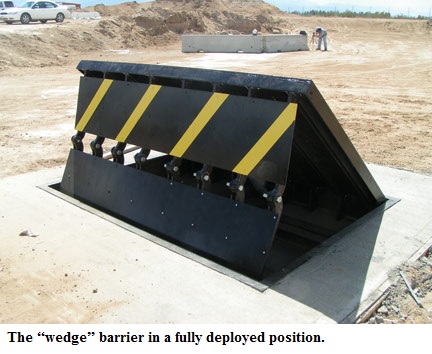

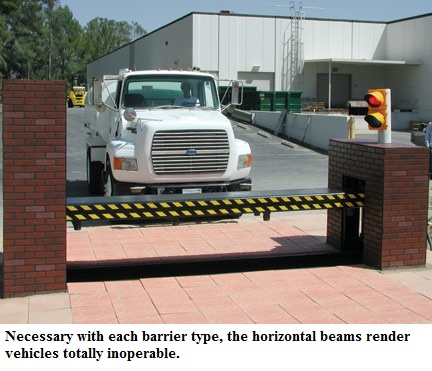

The vehicle barricades, in their unguarded position (non-deployed), are stowed below the roadway surface. Drivers typically are not aware of these protective devices as they pass over them. Barrier types include raising bollards, wedges, and horizontal beams.

Powerful 2,500 PSI hydraulic cylinders are used to raise these large steel obstacles. Deployment speed is adjustable and varies from 5 to 15 seconds for normal speed to less than 2 seconds during an emergency.

The barriers are not required to be operable after a vehicle collision, but many remain fully functional.

Typically, the barriers are deployed by security personnel via operator panels. These operator panels are sloped-front consoles equipped with 22mm pushbuttons, indicator lights, keyed switches and a mushroom-style emergency pushbutton.

Barricades can be maintained in the deployed or non-deployed state. For high security installations, or during periods of elevated threat levels, barriers are always deployed and lowered only for passage of vehicle traffic after security clearance. Multiple barricades in series make up a vehicle trap, called a sally port, for clearing vehicles individually.

Guards can selectively deploy a barrier in any traffic lane at normal deployment speed. When a serious threat is perceived, operating an emergency fast-response mushroom-style pushbutton raises all barriers at full speed. Other, more autonomous, deployment methods include vehicle speed sensing radar, roadway detection loops and wrong way detection sensors. Inadvertent operation is avoided by vehicle presence detection using FG series through-beam photoelectric sensors, offered by AutomationDirect, over barrier surfaces, and/or via detection loops buried in the pavement immediately before and after the barriers.The control system monitors barrier position using AutomationDirect’s AT series inductive proximity switches. Barrier proximity switch status is used in the PLC program to report barrier positions, display indication on the operator panels, and to control other devices such as traffic signal lights, electric gate arms, warning horns/ annunciators and strobe lamps.

A main hydraulic power unit generates fluid flow and stores high-pressure hydraulic energy in accumulators for instant use. The stored energy also allows barrier operation during complete loss of facility electrical power. Battery-backed power supplies can keep the control system active for several hours without main power. All hydraulic power unit functions are controlled by AutomationDirect’s DirectLOGIC programmable logic controllers (PLCs). Inputs from the operator panels initiate operation of the hydraulic solenoid valves. Cutler-Hammer motor controls operate the electric motors driving the hydraulic pumps.

Using information from fluid pressure, level and temperature switches, the PLC program monitors the pumps to prevent operation outside safe parameters. The PLC sequences pump starts to reduce facility power amperage draw and to distribute pump wear evenly among multiple pumps. Any power unit problems are reported by a warning indicator on the operator panel. These systems must operate unattended in extreme environmental conditions, from the coldest temperatures at US Air Force bases in Alaska, to the hottest temperatures at the US Embassy in Cairo, Egypt.

The first generation of hydraulic units used one, two or three DirectLOGIC DL05 PLCs in master/slave configurations. The ability to expand the system incrementally to match the application provided the best solution at the lowest cost. The PLC memory module (D0-01MC) was a convenient way to make changes to the program at Intertex Barriers and simply send the module to the site to be swapped out. The real-time clock feature of the memory module was utilized to date and time stamp information for data logging input and output changes. In the event of an incident, data was readily available as a contact sequence histogram. The PLC stored several days of data before being overwritten.

Color touch panels located in the master security control room are used to display status and control the barriers. Three-dimensional drawings of the barriers deploying/stowing were converted into graphics that show the barriers raising and lowering during operation.

The latest generation hydraulic units use DirectLOGIC DL06 PLCS. Smaller systems use a single PLC, while larger systems use up to three. Expansion slots for additional modules allow for flexible input and output configurations. AutomationDirect’s Hubbell-Wiegmann NEMA 4 electrical enclosures protect the electronics.

The enclosures house the PLCs, power supplies, motor starters, circuit breakers, fuses, terminal blocks, sensor electronics and accessory relays. If required, connectivity to provide remote operation and to report system status to higher-level security systems is accomplished using PLC/PC hardware with either DeviceNet (D0-DEVNETS) or Ethernet (H0-ECOM) communication modules.

To help lower production costs and remain price competitive, AutomationDirect products are used throughout the systems. The support and response from AutomationDirect has made a big difference in the ability to service customer’s requirements in a timely, effective manner. As a vendor, AutomationDirect is one of Intertex Barriers top suppliers.

By Jeff Anderson

Intertex Barriers, Inc.

A Division of Boon Edam Tomsed

Originally Published: June 1, 2007