Automation methods used in a distillery are adapted for use in the fermentation process at a brewhouse.

By: Avi Aisenberg, CEO and Proprietor at South Florida Distillers

South Florida Distillers is the oldest distillery in the city of Fort Lauderdale, Florida. The company is now branching out into the design business by working with 26° Brewing to help them brew world-class craft beers.

Greg Lieberman is the founder and owner of 26° Brewing in Pompano Beach, Florida. He started out as a homebrewer making 10 gallons per batch in a variety of locations such as the garage, the kitchen, a sibling’s backyard and in a barn. Greg’s homebrew career saw about 100 batches in four years, totaling one thousand gallons of beer.

Once he perfected his craft, and with the help of South Florida Distillers, he scaled up the 10-gallon recipes and now produces his beers in a state-of-the-art 30 barrel brewhouse (Figure 1). At 26° Brewing, a sports bar, meeting and retail area, and a fully functioning brewhouse are under the same roof. The brewhouse can produce 30 barrels per batch, with 31 gallons per barrel for a total of 930 gallons per batch, or 7440 pints.

Distillery Gets the Brew Flowing

Before creating South Florida Distillers, I took over the family plastics recycling and manufacturing business, now sold. We recycled commingled large bulk plastics into plastic shipping pallets, primarily for the cruise line industry, using a unique structural foam injection process. It used the recycled plastic and made an 18 pound plastic pallet every two minutes using a single-shot injection molding process.

The machines were all from the 1970s and 1980s, so most were relay controlled using a 25-foot-long control panel full of hardwired relays. Re-building the hydraulics and controls on the recycling machines using AutomationDirect micro modular PLCs was a great learning experience, and it made the equipment more productive and easier to support.

After selling the recycling business, I started South Florida Distillers, a craft rum distillery. I have designed and automated portions of the in-house rum distillery using a wide variety of AutomationDirect control hardware. Based on a demonstration of a 250-gallon distillery fermentation tank using an AutomationDirect PLC and temperature controllers to the owner of 26°Brewing, our company was selected as the designer and integrator of the system for their new craft brewery.

Of course, it helped that the owner of 26°Brewing, Greg Lieberman, was a longtime family friend. His dad was my pediatrician, and we grew up on the same block back as children. When Greg decided to open the brewery, we discussed in great detail the functionality he wanted yet couldn’t find on the market. That was music to my ears, so I got started on the design.

South Florida Distillers designed and programmed a touch screen fermentation temperature control system for a new brewery installation at 26° Brewing. The controller is responsible for precise temperature stabilization and control of seven tanks initially and is expandable up to 16 tanks.

Crafty Brewing Steps

There are many steps to brewing beer, and this is not a complete list of process steps. During the initial steps, the grains are placed in water in a tank and heated, similar to a pasteurization process, to extract the starch. The grains are then strained out and the liquid is boiled. This converts the starch to sugar and also removes some water, increasing the sugar content of the liquid. After boiling for a time, the liquid is quickly cooled by running it through a plate heat exchanger. This cooling process also provides the opportunity for heat recovery for reuse in upstream processes.

Once the beer is cooled, the tank is drained and pumped to a fermentation tank. Typically, these fermentation tanks need to be cooled due to the heat produced by the metabolic process of converting sugar to alcohol. The fermentation part of the brewing process is where the beer spends most of its time. For example, Pilsner beers ferment about four days, and Lager beers take about two weeks. Controlling temperature during this “cold side” fermentation process is critical to the quality of the finished product.

After fermentation, the beer is transferred to the brite tank where it goes through a final quick cool, and a racking process to remove the beer off the top of the yeast, which settles to the bottom of the brite tank. From there, secondary fermentation may occur, such as adding fruit. Once this is complete, the final product is transferred to the cold liquor tank.

Automation System Details

The automation system consists almost entirely of AutomationDirect components in the following categories:

- Programmable Controllers

- Operator Interface

- Circuit Protection

- Enclosures

- Switches

- Distribution Blocks

- Multi-Conductor Instrumentation Cable

- DIN-rail

- Wire Duct

I have always loved working with AutomationDirect’s products. The website is easy to use and they always have what I need. The shipping terms are great, especially since the warehouse is located relatively close to us in the adjacent state of Georgia. Their tech support has never failed me, and their return policy is on point, although we’ve rarely had to use it.

The automation system is based on an AutomationDirect PLC (Figure 2) and touchscreen human machine interface (HMI). The system is being used to control the fermentation process in five stainless steel 30-barrel conical fermenting tanks adjacent to the brew house. These tanks are located in the rear of the facility, with a tap room in the front. The windows behind the bar allow visitors to see the five fermentation tanks, one stainless steel brite tank, and one stainless steel cold liquor tank in the back room.

As of now, the brewery automation system only controls the temperature of these seven glycol-jacketed tanks, but it could be expanded to include pump and motor controls, steam flow control and much more in the way of automating processes which are currently done manually. The automation system was also built to accommodate the future addition of fermenting tanks with minimal hardware changes and a simple software update.

Fermentation Control, The Cold Side

The general purpose of the cold side automation system is processing monitoring, process control, data acquisition and data logging of the fermentation process. Much of the process upstream of fermentation is manually controlled.

Although individual PID temperature controllers could be used at each of the seven tanks, the single AutomationDirect controller solution was a better solution and less expensive. The added value from the PLC comes from the remote viewing and control of the process, and the ease of training new users. The design also required less work on behalf of the electrician, and will be less expensive when it comes time to expand the brewing process.

The PLC includes two multipoint AC output modules to control the 19 solenoid-actuated water valves. Seven RTD sensors are connected to PLC input modules to measure tank temperatures using clean-in-place RTD probes. Each of the five fermentation tanks has three cooling zones, with cooling solution flow controlled by one valve per zone, for a total of three valves per fermentation tank. The brite and cold liquor tanks each have two cooling zones and valves.

The temperature of each fermentation tank is controlled by a PID control algorithm running in the PLC. For each tank, a PID loop uses the tank RTD sensor as the process variable input, and controls three ball valves via the PID controller output. These valves control the flow of a glycol/water solution at each tank jacket. A ramp/soak pattern can be programmed to last for days or weeks based on the beer being fermented.

Temperature control for the brite and cold liquor tanks is similar, except there are only two cooling zones and valves per tank.

HMI and Remote Access

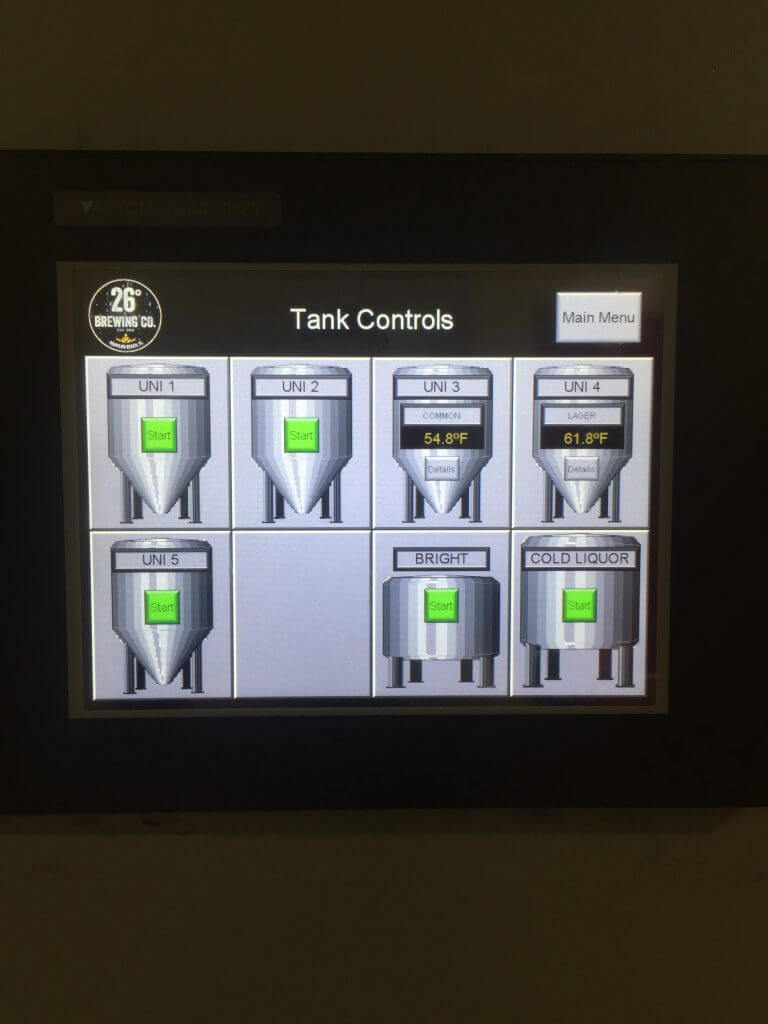

The HMI has a custom-designed user interface which mimics the flow of product through the brewery (Figure 3). The controller and HMI are networked together through an Ethernet switch, as is a wireless access point. This access point provides network connections for both local and remote access to the C-more touchscreen via iPad, iPhone and Android apps running on smartphone or table mobile devices.

This system adds tremendous functionality and makes interaction with the automation system more user-friendly and easier to setup than with multiple temperature controllers. The automation system provides data logging locally at the PLC, and remotely through the Ethernet switch.

A free app allows mobile devices to remotely access the HMI. Once remote access is enabled at the HMI and the app is installed on the mobile device, duplicate screens from the HMI can be viewed and controlled remotely from the mobile device.

All of the process data is emailed to a selected group of users at periodic intervals or upon an alarm condition. Email addresses and recipients can be added or deleted at the HMI. High and low temperatures alarms, deviation alarms, and other conditions can each trigger an email. Text messages can also be sent to smartphones with the HMI.

Installation and Results

All wiring to and from the electrical cabinet including power wires, RTD temperature sensors and cooling valve control wires were installed by a licensed electrician. The system startup was executed by me and Greg Lieberman. The initial startup involved training the PID algorithms for the three different sized fermentation tanks.

Each fermentation tank has three valves controlling the flow of glycol to the cooling bands. Training the PID loop for each tank required opening and closing the valves to see how quickly the temperature of the water in the tank changed.

Beer took a bit of retraining due to the exothermic reaction of fermentation, which is of course not present with water. Overall it took 6 to 12 hours per tank to train the PID cooling loop, mainly because 1000 gallons of beer are slow to heat or cool.

The system performs as expected and the client was able to sleep better knowing that each batch of beer has a watchdog to notify him and other operations personnel of any mishaps. There is always room for additional automation throughout the brewery. There are additional designs for motor controllers and valve routing systems ready to be built, just waiting for the right time.

Check out the AutomationDirect.com website today to explore products that can help your company control its own automation destiny.

Originally Published: December 2019