Reliable, rugged, and economical automation components are essential building blocks for bringing high-tech into consumer-facing applications.

After working for more than a decade on industrial and automation projects, Grayson Dawson founded Hop Robotics to bring high-technology robotic serving systems to the food & beverage and hospitality sectors. He wrote a success story article that ran on Automation.com in October 2022, titled A Top Shelf Pour. Here’s a summary, click on the link above for the full text.

While there is a common understanding that automated robotics improve the speed and accuracy of industrial operations, the technology is only moving slowly into the consumer arena due to cost, reliability, and safety concerns. Asia is far ahead of the rest of the world in these types of applications, and there is a lot of interest and hype elsewhere, although many solutions are simply far too complex and costly.

Understanding the Market

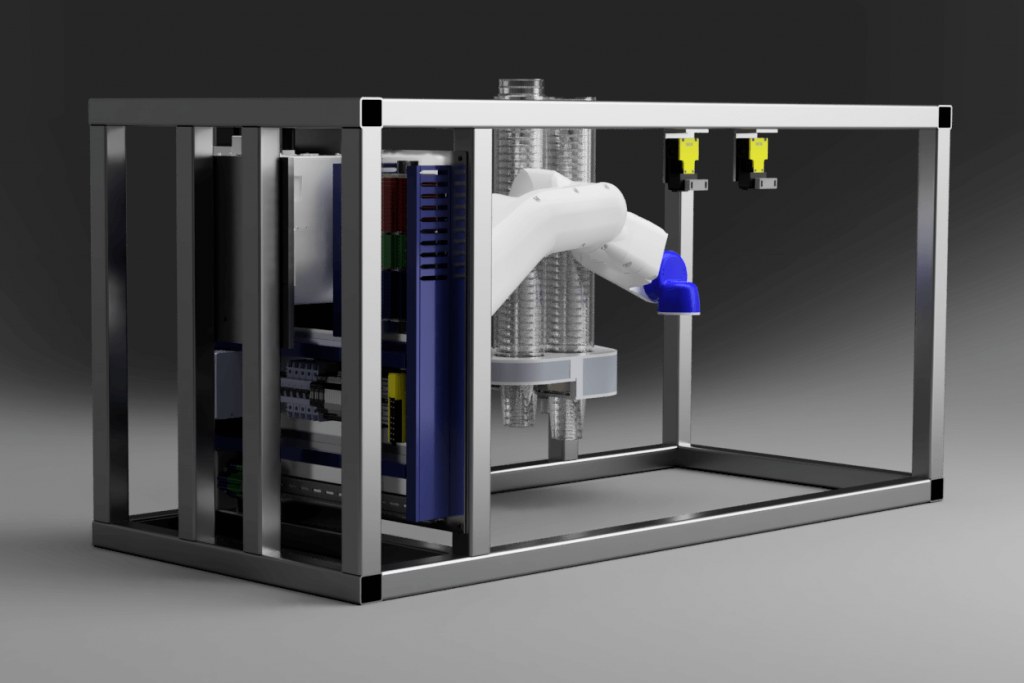

Hop Robotics took all these factors into consideration as they researched market needs for an automated beer dispensing platform suitable for all types of hospitality venues. The solution had to be easy-to-use, highly efficient, and cost-effective, requiring the use of commercial off-the-shelf (COTS) components and software. Automation would be a key factor, but just enough to make the system functional and supportable without driving up costs.

Building in Reliability

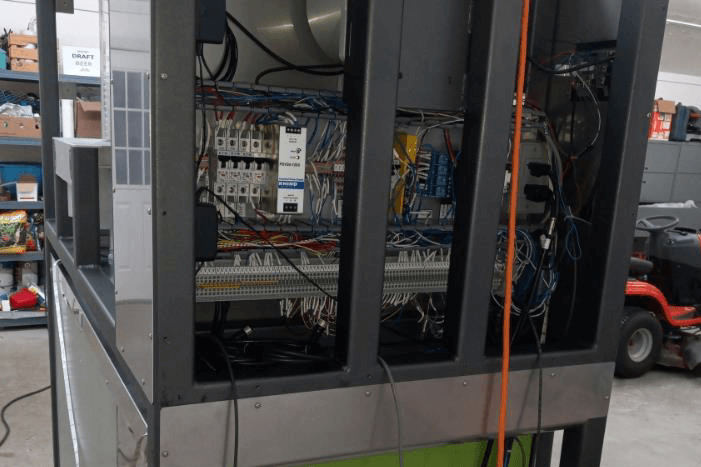

Many functions would require coordination, including the robotic arm control, cup handling devices, point-of-sale systems, socket messaging to external systems, and visualization of menus, branding, and queuing. Creating a compact form factor using components designed to withstand the rigors of transport was also a key concern.

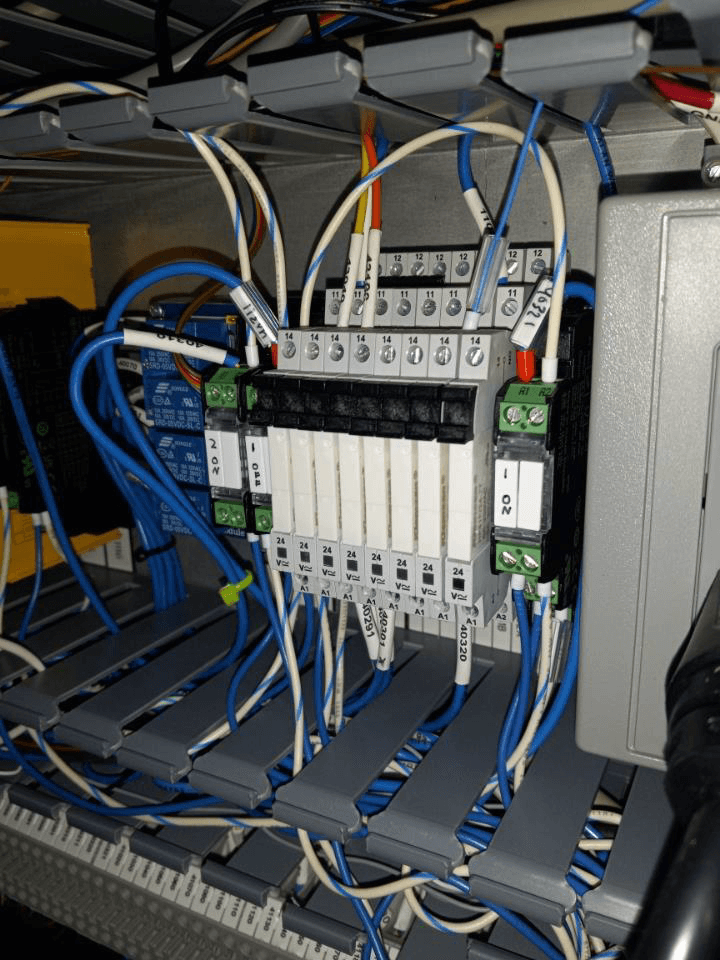

The Hop Robotics team already had previous experience with the performance, quality, availability, and value of AutomationDirect products, so they selected circuit breakers, relays, terminal blocks, power supplies, and more from the portfolio.

AutomationDirect provides easy access to product data and CAD files, so the team was able to take advantage of 3D modelling tools to choose products like slim relays and double-level color-coded terminal blocks to optimize control panel space and usability.

Many industries struggle with limited product availability, but Hop Robotics found that AutomationDirect—with a depth of brands along with their own line of products—provided a wide range of options, simplifying the search for components.

The resulting design has proceeded through two iterations, and it is impressive in appearance and operation. Users are delighted at how this mobile system pours beer accurately and rapidly.

Trial operation has proven the equipment to be reliable in service. Hop Robotics has used the right amount of technology to create a design that will outlast novelty concepts, with a focus on required functionality, a small footprint, and low cost.

All figures courtesy of Hop Robotics