ApplicationApplication StoriesCompany TopicsEntertainmentIndustryLearning ResourcesMachine ControlMotor ControlsNewsOnline BlogPLCProductProgrammable Control

Let’s Ride the Roller Coaster! - An AutomationDirect Case Study

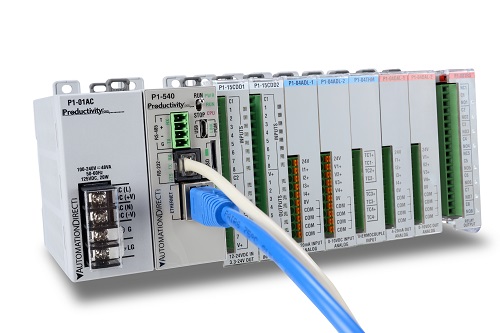

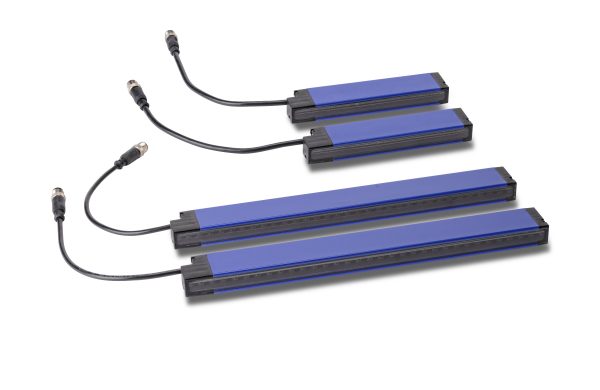

Manny Salazar, the Manager at Automated Integration LLC, wrote an article titled Roller Coaster Overhaul for the April 2018 issue of Automation World. The article told the story on how Automated Integration replaced an old PLC, a bunch of relays and what seemed like miles of wire when upgrading the control and safety system on…