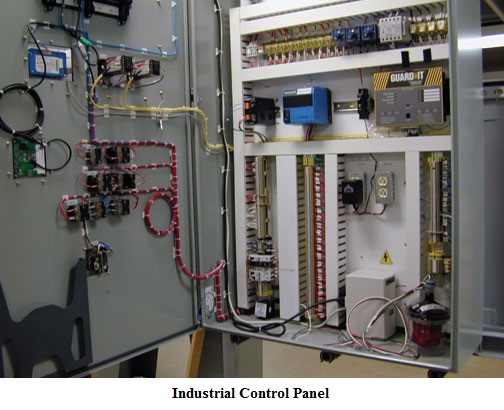

The purpose of the National Electrical Code® (NEC®) is the practical safeguarding of persons and property from hazards caused by using electricity. The NEC is prepared by a committee made up of a Technical Correlating Committee and 19 code-making panels. The committee’s responsibility is to create documents specifying code, which when adhered to, minimizes the…

In each issue of the Automation Notebook we feature a section of brainteasers. These are the brainteaser answers from Issue 4, 2005 of the Automation Notebook. The brainteaser questions are repeated in black. The answers to the brainteaser questions are highlighted in red with explanations. You can view the brainteasers from Issue 4, 2005 without the answers here: http://library.automationdirect.com/brainteasers-issue-4-2005/…

1. “Rebates on PLCs” A company that sells overpriced PLCs and needlessly expensive AC Drives decides to offer their customers a rebate. They offer $250 to each PLC customer, and $400 to each customer who bought an AC Drive. Unfortunately, the company has lost track of the number of customers who have purchased each product,…

+Tech TopicsAutomation NotebookFYIIssue 4 – 2005Learning ResourcesNotebook IssueProductVariable Speed Drives

VFDs Frequently Asked Questions

AutomationDirect’s technical support team has compiled a list of customer frequently asked questions for many of our products. The complete listing can be found on the technical support page of our Web site. Here are some of the frequently asked questions for variable frequency drives (VFD). FAQS Q: What is sensorless vector control?A: Sensorless vector control…

+Tech TopicsAutomation NotebookIssue 4 – 2005Learning ResourcesNotebook IssueProductProgrammable ControlTech Thread

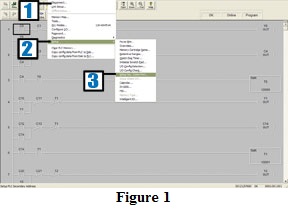

A User's Guide to Configuring Serial Ports for DirectLOGIC PLCs: Part Two

In the previous issue of Automation Notebook, Winter 2005 Issue 3, we discussed the communications capabilities of Port 2 on the DL06, DL250-1 and DL260 DirectLOGIC CPUs. We covered networking, wiring diagrams and protocols. In this issue we will discuss how to configure the communication port using DirectSOFT programming software while connected to the CPU….

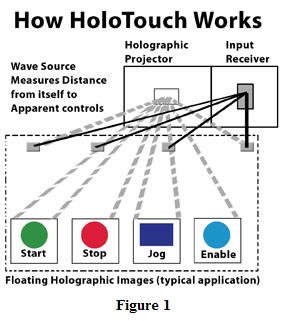

In April 2002, HoloTouch®, Inc., a Delaware corporation with offices in Darien, Connecticut, announced that its founder and President, R. Douglas McPheters, had been granted a U.S. Patent for his “holographic control arrangements.” This innovative technology allows operators to actuate and control a wide variety of electronic devices by simply passing fingers through colorful, three-dimensional…

Automation NotebookIssue 4 – 2005Learning ResourcesNotebook IssuePLC SpeakingProductProgrammable Control

PLCs Evolving Toward Motion Control

In our fast paced and economically stressed industrial world, flexibility is becoming a higher priority for those who are specifying automation systems. Users need multi-functional control, simple connectivity and easy access to process data, all wrapped up in a nice neat package. Today’s Programmable Logic Controllers (PLCs) have to be much more than the relay logic…

AutomationDirect Assists Team Buffalo In 2005 DARPA Challenge Team Buffalo, a small group of highly talented individuals skilled in bringing abstract technical visions from conception to reality, has committed to participating in a Defense Department research and development initiative aimed at advancing robotics technologies for future military use. The initiative, known as the DARPA Grand…

We have added several exciting products since our last edition of the Automation Notebook. Here are some highlights about some of those new products including: Non-fused disconnects, 22 mm and 30 mm pilot devices, 115 VAC GS2 drives, ECT promis•e draw packages Version 5.06, Signal conditioners. Non-Fused Disconnects AutomationDirect has introduced a line of non-fused…

+Tech TopicsAutomation NotebookFeature StoryIssue 4 – 2005Learning ResourcesMotion ControlNotebook IssueProduct

Motion Control System Choices

Motion control is generally understood to mean the use of servo and/or stepper systems as the “muscle” to move a given load. These motion control systems are capable of extremely precise speed, position, and torque control. Applications which require positioning of product, synchronization of separate elements, or rapid start/stop motion are all perfect candidates for…