In today’s modern pneumatic systems, there are a variety of choices available to get the air preparation systems, valves and cylinders connected. Most designers use flexible pneumatic tubing or hose rather than rigid tubing, and many different types of both are available. Fittings offer many choices as well to meet the needs of a wide…

+Tech TopicsCover StorieseBookIssue 35 - 2016Learning ResourcesNotebook IssueOnline OnlyPneumatic eBookPneumaticsPneumatics eBookProduct

Are Pneumatic Components Compatible?

The industrial pneumatics market is fairly mature. While there continues to be new developments and technologies, many of the tried and true core products have been around for years. One advantage that this can offer to both system designers and end users is often having several brands of pneumatic components that are interchangeable with each…

In order to perform a task using pneumatics, there needs to be some way to initiate, monitor, and stop the process. This is where a simple pneumatic system becomes electro-pneumatic. Electro-pneumatic systems integrate pneumatic and electrical technologies into one system where the signal/control medium is electrical and the working medium is compressed air. In this…

+Tech TopicseBookLearning ResourcesOnline OnlyPneumatic eBookPneumaticsPneumatics eBookPneumatics MoreProduct

Pneumatic System Design Considerations

Pneumatic systems as a whole can be simple, but this simplicity can be deceptive when it comes to selecting components. For instance, there are thousands of types, sizes, and variations of cylinders and valves, from off-the-shelf versions to custom designs. The sheer number of choices can be overwhelming, especially when options such as sensors are…

Reducing energy consumption is a priority in almost every manufacturing plant and industrial facility, as no company can afford to throw money away using machines and processes that waste energy. Because pneumatic systems are abundant throughout manufacturing and account for a large share of a plant’s power costs, it is extremely important that they run…

+Tech TopicseBookIssue 35 - 2016Learning ResourcesNotebook IssueOnline OnlyPneumatic eBookPneumaticsPneumatics eBookProduct

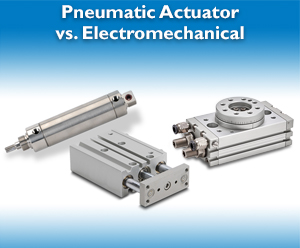

Pneumatic Actuator vs. Electromechanical

In materials handling and assembly there are many ways to move an item from one location to another. Conveyors are one way and are widely used, but they can only move objects in a fixed path, limiting their use in more precise manufacturing applications. When more accuracy is required than a conveyor can deliver, such…

Have you noticed a gap in the industrial controllers market? PLCs are good at handling your low end applications, but on the high end, many suppliers want to push you into distributed control systems or other expensive and complicated solutions. What’s needed is a controller in the middle, one not too big and not too…

+Tech TopicsApplicationCommunicationsLearning ResourcesMachine ControlOnline BlogOnline OnlyOperator InterfaceProduct

Giving OEMs Freedom Gets Best Results

Owners, managers and other decision makers in production facilities should focus on how purchased equipment fills production needs to get the best pricing, delivery and support from machine and process skid builder OEMs. Unfortunately, some instead focus on component specification details, which can make it difficult for OEMs to provide the best pricing, delivery and…

+Tech TopicsAutomation NotebookeBookIssue 34 - 2016Learning ResourcesNotebook IssuePneumatic eBookPneumatics eBook

Why Use Pneumatics?

In manufacturing facilities, compressed air is so widely used that it is often regarded as the fourth utility after electricity, natural gas and water. But compared to electricity, compressed air is more expensive, so why is it so widely used to drive factory automation systems?

+Tech TopicsCommunicationsethernet explosionLearning ResourcesOnline OnlyProductProgrammable Control

EtherNet/IP | Automation Notes

As technology advances, so does the speed at which it communicates. And with the advances made in industrial controls, the need for high-speed data transmission became a priority. As a result, Ethernet communication became more and more prevalent in industrial networks and prompted many industrial equipment manufacturers to implement their own Ethernet communication protocols. These…