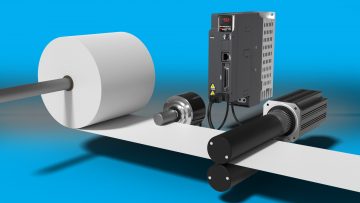

Servo systems are a leading way to implement high-performance motion control, and the latest servo drives offer functional, programming, and diagnostics capabilities to help users quickly create and commission solutions. Chip McDaniel, technical marketer at AutomationDirect, wrote an article posted July 2021 on Control Design titled Servo Systems Lead the Way to Implement High-Performance Motion…

Stepper motors use specialized control methods to achieve better precision than standard variable speed motors, while avoiding the expense and complexity of servo systems. For industrial automation, the term motion control usually means using an electric motor to positively drive the position, velocity, and acceleration of a physical system. Pneumatics are economical, and hydraulics can…

Stepper motors can be the best option, even for precision motion control applications, while avoiding the expense and complexity of servo motors. Standard AC induction and DC motors can only produce basic motion control, and servo motor solutions provide exceptional performance but drive up costs and complexity. For many motion control applications, stepper motor solutions…

Stepper motors play an important role for motion control applications requiring more precision than standard variable speed motors, but not warranting the expense and complexity of servo motors. For many applications, a stepper motor solution occupies the sweet spot of providing the required performance, but at a much lower cost than servo solutions. This white…

A stepper motor (sometimes called a step motor or stepping motor) is a DC motor with a fixed number of steps that make a full rotation. The motor can be commanded to move to any one of those step locations and hold position without any need for a position sensor – assuming it is properly…

ApplicationApplication StoriesAutomation NotebookAutomationDirect SpotlightDiscrete SensingEducation/DIYIndustryIssue 37 - 2017Learning ResourcesMotion ControlNotebook IssuePLCProductProgrammable ControlStudent SpotlightTest and MeasurementVariable Speed Drives

Beam Testing at Portland State

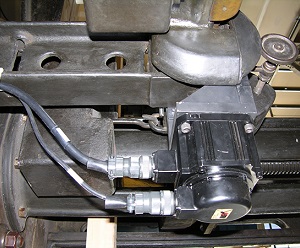

For their undergraduate senior capstone project, a team of Mechanical Engineering students at Portland State University (PSU) recently designed an electronic system upgrade for the control system of a 100-year-old beam testing machine. Using a range of AutomationDirect parts, the purpose of the project was to make the operator experience comparable to modern machines.

+Tech TopicsAC Motors and ControlsLearning ResourcesMotion ControlMotorsOnline OnlyProductVariable Speed Drives

Selecting Motors for Industrial Applications

Efficient use of motors is always important, but there are many other things to consider when specifying an electric motor. Mechanical and environmental considerations are on the list, as is the application and operation. All of these factors are important, but the application is where the selection process should start. How to Select a Motor…

Linear motion actuators are used in factories for pick and place operations, CNC lasers and routers, complex adhesive application or whenever super-precise and accurate positioning is required.

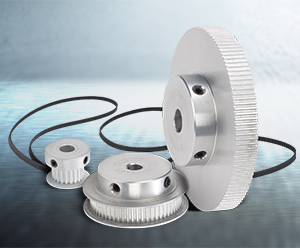

October 5, 2016 – AutomationDirect’s SureMotion line of motion control products now includes additional synchronous timing belts and pulleys for small motor applications. An excellent choice for many industrial applications, SureMotion MXL series timing belts are 1/4-inch wide, have a 0.080-inch pitch, and are available in neoprene with fiberglass reinforcement and urethane with polyester reinforcement…

ApplicationApplication StoriesCompany TopicsDrivesEducation/DIYIndustryMachine ControlMotion ControlNewsOnline OnlyProduct

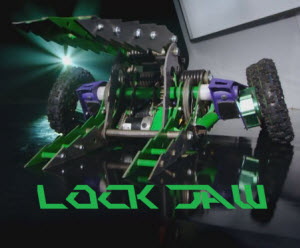

Lock-Jaw2 Robot Competes in BattleBots TV Show Using AutomationDirect Parts

Robots Activate! Is a familiar phrase to those fans who follow the BattleBots competition which just completed its 2016 season broadcast on ABC Television in the United States. One of the BattleBots competition veterans, Donald Hutson, has been involved since the show began and has been on the robot combat circuit since 1986.