The journey from theory to reality can be fraught with the unexpected and not as clear-cut as it seems on paper. Even the most direct path from concept to completion can have external influences, that might seem irrelevant at the time or might not be known at all, which can cause undesirable results in the…

Picking the right hardware is critical, but make sure to include the controller programming software in the evaluation process as it will determine ease of use. When selecting a controller for factory automation, it’s not just about whether a PLC, PAC or PC should be used. It’s also about defining the requirements for the application,…

As with any engineering decision, it’s always best to put it on paper first to see the “big picture”. The same holds true when choosing the most effective PLC for your application. This choice depends on a number of factors and the following steps serve as a checklist of things to consider when determining PLC…

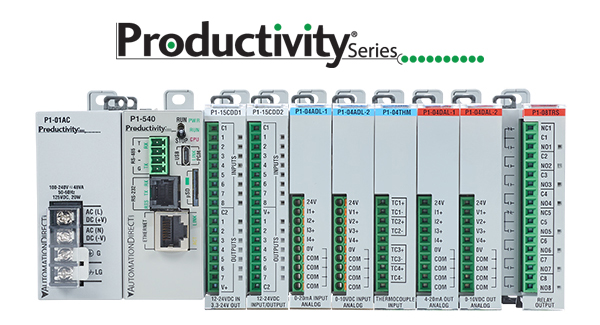

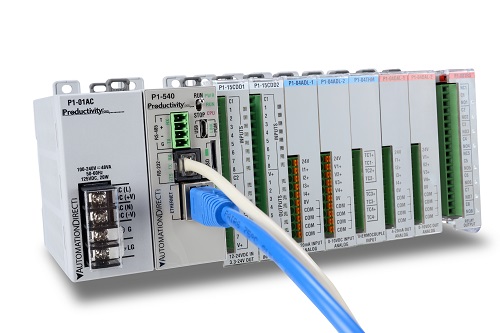

With the release of the Productivity1000, the newest and smallest of the Productivity Series controllers, we now have a scalable product offering that gives you the flexibility to design your control system program for a broad range of applications and sizes, without sacrificing functionality. The Productivity1000 (P1000) is a compact, stackable micro Programmable Logic Controller…

KCC Software fuels the safe and reliable upgrade of a highly flammable, corrosive and toxic gas distribution system for semiconductor tools. A semiconductor manufacturer of memory and drive head technologies, Headway Technologies in Milpitas, California is a part of the TDK group of companies, the largest independent recording head supplier in the disk drive industry….

ApplicationApplication StoriesCompany TopicsEntertainmentIndustryLearning ResourcesMachine ControlMotor ControlsNewsOnline BlogPLCProductProgrammable Control

Let’s Ride the Roller Coaster! - An AutomationDirect Case Study

Manny Salazar, the Manager at Automated Integration LLC, wrote an article titled Roller Coaster Overhaul for the April 2018 issue of Automation World. The article told the story on how Automated Integration replaced an old PLC, a bunch of relays and what seemed like miles of wire when upgrading the control and safety system on…

AgricultureApplicationApplication StoriesIndustryLearning ResourcesMachine ControlOnline BlogPLCProductProgrammable ControlSimple PLC

Are CLICK PLCs Really That Simple? - A DIY PLC Project

By now you know that CLICK PLCs are considered one of the easiest PLCs to use and the perfect choice for beginners and small applications. I know you know that, because I am one of the many who keeps bringing it up. As a technical marketer for AutomationDirect, my job is to let you know…

2017 proved to be a stellar year for U.S. manufacturing with strong growth in 16 of the 18 manufacturing industries polled for ISM’s December 2017 survey. With machinery and computer and electronic products leading the way, U.S. manufacturing is expanding at a rate not seen in 13 years according to a BloombergMarkets article on the…

Jeff Payne, the Automation Controls Group Product Manager at AutomationDirect, penned an article titled Product Design: Incorporating Commercial Technologies into Industrial Controllers for the February 2018 issue of Control Engineering. The article looked at some of the commercial off-the-shelf or COTS technologies used in industrial controllers. These technologies include Ethernet, FPGAs, USB, MicroSD and others….

In addition to following industry regulations, internal company standards should be created and adhered to so existing and new plant automation system designs are consistent. These internal standards should help define best practices and provide clear guidelines for system design, and for hardware and software used on the factory floor. If not, you may have…