In 2022, OSHA reported 5,486 fatal industrial accidents. Many more accidents resulted in injuries or lost work productivity. These accidents may have been avoidable. Proper training and machine safeguarding could’ve prevented many of these accidents, reducing injuries, downtime, and deaths. Industrial safety starts with training. In addition to training, proper machine protection is another layer…

It can happen at the best workplaces and in the safest environments but it’s always chilling news when you come into work and hear that there has been a workplace injury. Whether you are in charge of safety, are a production manager, or are a plant manager, so many questions go through your mind at…

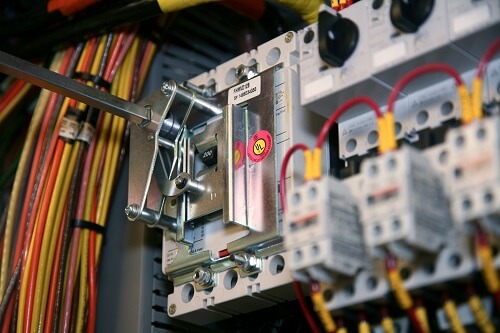

Designers can improve personnel safety by incorporating modern products and technologies, and by following a “design for safety” approach. Marty Kronz at AutomationDirect wrote an article for the February 2023 issue of Applied Automation. Titled Addressing Electrical Safety Hazards, this article identifies how some newer products, sometimes in combination with automation, can increase the effectiveness…

Industrial automation safety designers should implement a hierarchy of controls. Josh Draa, PLC Product Engineer at AutomationDirect, wrote an article for the August 2022 issue of Applied Automation. The article is titled Implementing a Hierarchy of Automation Safety, and it describes the importance of project and operations. Responsible industrial automation safety design requires a combination…

There are many safety devices available to ensure machine safety and to detect personnel entering unsafe areas. Cable pull switches, safety light curtains and interlock switches (non-contact and the many types of tongue interlock switches) are just a few of them. Most of you have probably heard of, or used, these devices in some capacity,…

While we sometimes say things like “safety first” or “safety is no accident”, and I’m sure you’ve heard, “safety is a choice”, there are times when safety details are overlooked. We have the best of intentions but can be negligent regarding full safety protocol. Have you ever bypassed a safety device to save a few…

Safety standards are vitally important to follow, understand, and implement to eliminate and avoid injuries to personnel from machinery. This is our biennial update as to major changes to American National Standards Institute or ANSI code, and most specifically the B11.0 dedicated to “Safety of Machinery”. Since 1922, the B11 standards for machine safety were…

For industrial machinery and systems, designers must apply the right products for physical, electrical power, and automation safety. Kevin Kakascik, Technical Marketing Engineer at AutomationDirect, wrote an article for the May 2020 issue of Machine Design titled Electrical Safety on the Factory Floor. Here’s a summary, click on the link above for the full text….

Machine designers must consider many factors when deciding on safety system architectures for factory automation. Larry Reynolds, product engineer for safety components at AutomationDirect, wrote an article for the September-October 2019 issue of ISA’s InTech titled Integrated or Separate Safety Systems. Here’s a summary, click on the link above for the full text. Factory equipment…

Full coverage E-Stop protection around your machinery We all know the importance of having emergency stop devices near and around machinery. There are numerous regulations (ANIS, ISO, IEC) that define emergency stop device requirements. In short they all state that they are actuated by a “single human action”, should be used to de-energize equipment to…