If you’ve ever taken a long road trip, you’ve probably passed large fields of crops, which every now and then contained odd looking metal pipe structures on wheels stretching across the fields. These metal monsters, known as pivot irrigation systems, are used extensively in agriculture and have greatly improved the efficiency of the crop irrigation process.

As Dan Carter of Carter Pivot Service explains, “Pivot irrigation systems were designed to take a large portion of the manual labor out of irrigation and make it easier on the farmer to manage the process at multiple locations. Previous forms of irrigation systems were very labor intensive and required the water to be shut off to allow for movement through the field. The pivot irrigation system allows the farmer to start irrigating and only monitor the operation until the cycle has ended (pivot has made a complete or partial circle).”

Sow Much Better with Automation

Over the years, pivot irrigation systems have gone through various improvements and many options are available today including water, hydraulic and electrically driven versions. This application story, provided by Dan Carter, demonstrates how the controls for these pivot systems are being improved with automation with a pivot irrigation system upgrade in Morton, Texas.

In the fall of 2013, my dad, Tommy Carter, called me and asked if it would be possible to install a PLC in the control panel of a pivot irrigation system. I told him that it would definitely be possible and over the next few weeks we had several discussions which led to a list of components necessary to build the system. I have worked with AutomationDirect components throughout the last 15 years of my career as a controls specialist with great success. The cost effectiveness of components available at AutomationDirect, coupled with my previous experiences using the DirectLOGIC 06 (DL06 PLC) and the C-More (EA7-T8C) HMI, drove our decision to use their components to build our system.

AutomationDirect also provides shipping options for their products that keeps downtime to a minimum, a key parameter that made the decision to use them very easy for us.

The development of this system was ignited by the need for a control system built entirely out of off-the-shelf parts. Most of the major pivot irrigation system manufacturers use proprietary control systems that are built in-house at their factories. Unfortunately, they do not manufacture enough spare components to make them readily available when an emergency arises. To address this issue, we built our core control system entirely out of components from AutomationDirect. Most of the parts in our control system can be delivered overnight, and many within two to three days. This is crucial where crop irrigation is concerned. Waiting two or three weeks for control system components can damage a crop to the point that it cannot recover.

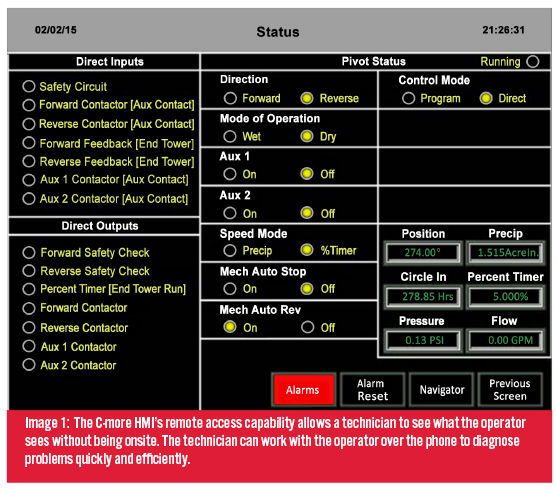

Our control system was designed around the DL06 PLC and C-More HMI. The controls were developed and improved while observing other major manufacturers’ systems in operation. The C-more HMI comes equipped with a web server and remote access capability. We leveraged this technology to control or monitor the operation of a pivot from anywhere in the world where internet access is available. Given this ability, to see what the operator sees without being onsite, a technician can work with the operator via phone to diagnose problems quickly and efficiently. Remotely accessing status screens (Image 1) will enable the repair technician to have the necessary parts before he drives to the customer’s location.

Pivot Position

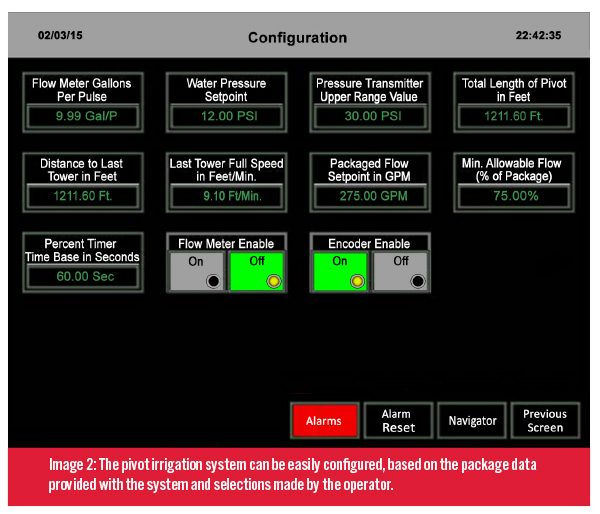

We designed the control system to be completely configurable to any standard non-specialty pivot irrigation system; it can be configured in a matter of minutes based on the package data provided with the system and selections made by the operator (Image 2). Before the pivot begins moving, it waits for water pressure to be verified. The operator can choose water pressure from a pressure transmitter or water flow from a flowmeter to indicate when the machine is ready to run “wet”, or ready to irrigate. In some cases, it is necessary to dead head the pivot back to a specific point which clears the way for farm implements or harvest equipment. This is an example of running “dry”.

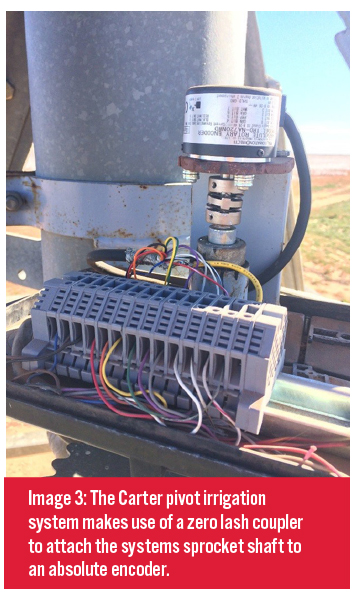

Much like the (older) control systems from most of the major manufacturers, our system uses an absolute encoder to determine the current position of the system [0° = North, 90° = East, 180° = South, 270° = West as displayed on the Status Page of the HMI]. Our system makes use of a zero lash coupler (Image 3) to attach the system’s sprocket shaft to the absolute encoder.

This coupling greatly improves the accuracy and repeatability of our position indication system and is a far better solution than the piece of rubber hose being used as an encoder coupling by some manufacturers. The absolute encoder in our system provides reliable position detection which is used to:

This coupling greatly improves the accuracy and repeatability of our position indication system and is a far better solution than the piece of rubber hose being used as an encoder coupling by some manufacturers. The absolute encoder in our system provides reliable position detection which is used to:

- Stop the pivot

- Reverse direction of the pivot

- Change the speed of the pivot

- Switch from wet to dry operation

- Switch from dry to wet operation

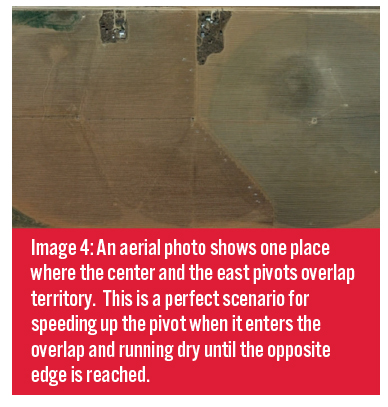

When viewing the aerial photo (Image 4), you can see one place where the center and the east pivots overlap territory. This is a perfect scenario for speeding up the pivot when it enters the overlap and running dry until the opposite edge of the overlap is reached.

Sometimes a farmer will grow different crops on the two halves of the circle. In this instance, one side of the circle might need more water than the other. The control system could be configured to slow the pivot down while tracking through the half of the circle that requires more water.

Controlling Crop Circles

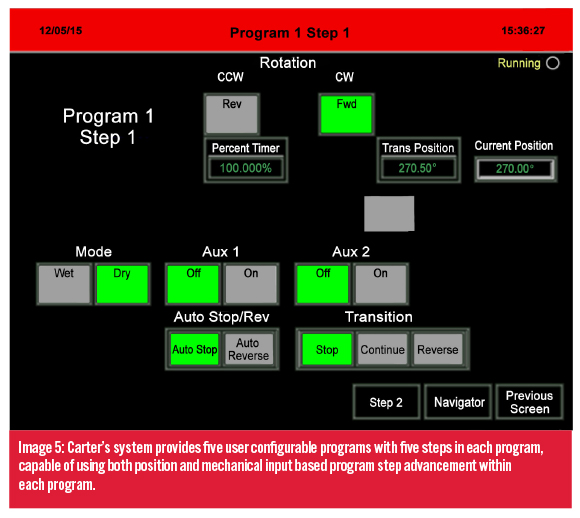

This system provides five user configurable programs with five steps in each program. The system is capable of using both position and mechanical input to advance the steps within each program. The pivot can reverse or stop while executing a program using a mechanical input from the tower that is equipped with the auto-stop / auto-reverse trigger.

Although there are five user programs available, sometimes a program will only need one step; other times all five will be utilized. An example of a one-step program would be as follows:

Run [Reverse][Dry] at [100%] of speed until position [270.5] is reached and [Stop]

The user will add steps as necessary until the program contains a [Stop] command in the Transition selection (Image 5).

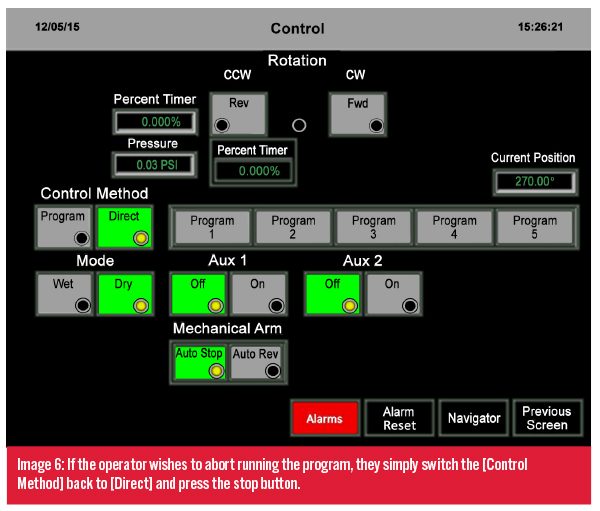

When the operator is ready to execute a program, he/she selects [Program] under the [Control Method] selection on the control page and then selects the desired program (1 through 5). This will begin execution of the program. If the operator wishes to abort the sequence, they simply switch the [Control Method] back to [Direct] and press the stop button (Image 6).

Alarms are captured with the time and date, and stored on the operator interface to make troubleshooting easier when a problem occurs.

While this feature may exist on new systems, it is a great enhancement for older systems that are still mechanically sound, but the factory control system is no longer operational.

Green Thumbs on the Go

Where more than one pivot exists on a farm, our system uses Ethernet radios to create a field network connected to the internet via a cellular internet modem. On farms that happen to be the homestead, our system can be configured such that all of the pivots on the farm network can be managed over the network even if the internet is down.

Our control system allows user’s access via the internet on multiple devices:

- Windows based Laptop/Desktop

- Apple iPhone, iPad and iPod

- Android phones and tablets

The connectivity using Apple and Android devices is made possible by the C-more application that is available for purchase on the App Store (Apple) and the Google Play Store (Android).

While our networking and remote connectivity uses the same basic infrastructure as the competition, the defining difference is that our technicians will also use the internet connection to the machine to help customers troubleshoot problems in real time without having to be onsite. Our technicians will also leverage the technology by taking control of the system remotely and showing the customer what steps are needed to successfully operate the system. This will reduce downtime for the customer.

At Carter Pivot Service our primary focus is to provide a highly reliable alternative to a basic control system, as well as a cost effective replacement for control panels that have become obsolete. We are solely focused on control systems and pivot service and do not build pivot irrigation systems. We are currently enhancing our control system’s capabilities and we hope to have it available for purchase in the near future.

To learn more about HMI’s, click here.

By Dan Carter, Carter Pivot Service

Originally Published: March 2017