Material handling is a broad industry that can mean many things and include many different technologies. At the most basic level, this can include racks, which simply hold products, or pallet jacks and fork trucks which require human intervention. More complex systems include conveyors, high-speed sorters, pick-to-light systems, palletizers, robotics, case erectors, identification systems, and the list goes on and on.

Some of these technologies just seem to know what they need to do without human intervention. If you are a consumer of these systems, they do the job so well that you might neglect the complexity involved. If you have ever designed or maintained a control system for a material handling application, you know these systems can be very complex.

Many components are involved in material handling systems, including motors, drives, sensors, pneumatics, controls, and safety products. When engineered properly, these components will work together in unison to efficiently move products, cases, or other materials from one location to another. Many things can go wrong or right depending on the system design, the quality of components, and how well the system is maintained.

If you are a seasoned material handling professional, or even if you are just starting in the industry, you know that finding these components can sometimes be challenging. Parts can be hard to locate, have very long lead times, or come at a premium cost. AutomationDirect is here to help with any components you may need to build, maintain, or repair your material handling control system. We have motors, drives, pneumatic components, controllers, safety products, and just about any type of sensor you may be looking for. We sell direct, meaning that we ship directly from our warehouses in Georgia to you quickly. Our award-winning FREE technical support is available if you need help selecting the correct product. Feel free to check out our library, which includes helpful information on our products and application stories from material handling and other industries. We would love the opportunity to serve you on your next material-handling project.

Practical Guide to Discrete Sensors for Industrial Applications

This eBook is for users who wish to advance their sensors knowledge. It covers a wide range of topics such as limit switches, proximity sensors, photoelectric sensors and more. Download Now –>

Detecting the Presence Of Objects – U Can Do It

A few quick examples of when to use the different kinds of industrial sensors to detect the presence of objects. Watch Now –>

PLC Package Handling

PLCs play a major role when it comes to material or package handling operations. Read Now –>

Practical Guide to Pneumatics – Updated Version

This eBook is for users who wish to advance their pneumatic knowledge. It covers a wide range of topics such as circuit symbols, component capability, integrating pneumatics with controls as well as improving pneumatic efficiency. Download Now –>

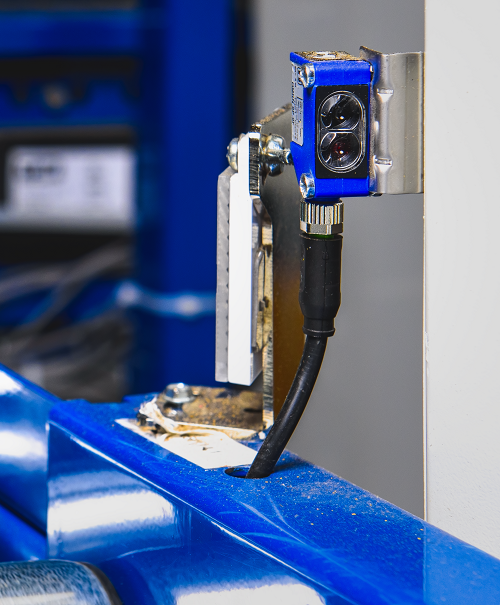

Light-Operate or Dark-Operate Photoelectric Sensors. Which is Better for your Application?

When choosing a photoelectric sensor for an application there are many things to consider. One of these considerations is whether to select a light-operate or dark-operate photoelectric sensor. Read now –>

What is a Safety Laser Scanner?

There are many safety devices available to ensure machine safety and to detect personnel entering unsafe areas. One of the newer safety devices on the scene, that you may be unfamiliar with, is the safety laser scanner. Read now –>

Get Schooled: AC Motor Basics

Jeff Payne, product manager for the drives & motors group at AutomationDirect, points out that alternating current (AC) motors are widely used in industry, primarily because of their high efficiency and ability to produce constant torque up to rated speed. Read more now –>

Dark & Shiny Object Detection Photoelectric Sensors Can Save the Day

It happens more often than we’d like in the material handling industry. During an accumulation conveyor start-up, the photoelectric sensors cannot detect the totes that the conveyor transports. Even worse is when a conveyor system that has worked fine for a long time is suddenly unable to detect new totes introduced into the system. Read more now –>

Automating a Donut Packaging and Labeling Line

When people hear the name Mel-O-Cream, they usually think of donuts. Founded in 1932 as a retail shop in Springfield, Ill, Mel-O-Cream International manufactures bakery products, primarily for wholesale distribution to supermarkets and bakeries. As donut manufacturing capacity and capabilities grew, so did the demands on our product packaging processes. Read More Now –>

Barcode Scanning in Factory Automation – U Can Do It

Barcode scanners are an important part of any factory line. Learning how to use them is a key skill. Let us help! Watch now!

Modern Controls Automate Rock Crushing

AutomationDirect PLCs deliver rock solid control! CTC Crushing partnered with InterConnecting Automation, an AutomationDirect system integrator, to modernize their rock crushing business. Learn how adding PLCs can be a major upgrade to your business. Read more here–>

Choosing VFD Control Modes

Choosing the right mode for your variable frequency drive, or VFD, is an important step to set up your drive correctly. Wondering which mode might be best for your application? Read More Here–>