In every haunted house, you’ll find automated props: chairs that rock on their own, slamming doors, rattling chains, drawers opening and closing as if by some supernatural force. These “tricks” enhance the “treat” of getting the life scared out of you. The process behind making a Halloween prop can be quite simple. Here is just one example of how a system integrator put used and spare parts to good use to frighten any trick-or-treater.

Trick or Treat

I purchased a DURApulse 60HP variable frequency drive (VFD) from AutomationDirect as a replacement for a customer’s damaged VFD. When the shipping container was delivered to my shop, I immediately knew what the wooden crate would become. This crate was just right the right size for building a Halloween Box. You may have seen similar Halloween props covered with labels, such as “Danger” or “Wild Animal”. I didn’t know at the time what the final result would be, but I could see “The Box” had potential.

I wanted The Box to give the impression that some type of wild creature was inside and wanted to escape. Because this was a hobby project, keeping down costs was a main objective.

As the owner of a system integration business serving multiple industries, I have accumulated spare components and hardware from retrofitting and upgrading applications. Case in point, the VFD shipping container came courtesy of a waste water pumping station application. The Box’s controller uses a CLICK programmable logic controller that was removed from a metal alloy chiller system. A C-more EA7 HMI, pulled from a fracking fluid control system, is used to provide displays and audio; I used pneumatic cylinders from previous applications and purchased a couple of new Nitra solenoid valves to assemble “the creature”. Finally, a Rhino power supply was borrowed from stock.

Due to my odd assortment of pneumatic cylinders, the next challenge was to figure out what I could do with what I had. A couple of squat cylinders would fit on the bottom of the box, placed between the legs at opposite corners to rock the box and make it look like there was something moving around inside.

To give the impression that the ‘thing’ or ‘creature’ inside the box is trying to escape, a cylinder is used to push the lid open. With a padlock hasp connected to the lid, the staple and lock appear to hold the lid closed. What the observer doesn’t know is that the staple is installed in a slot, concealed by the hasp, and a small cylinder is used to hold it down so the lid only moves up and down a little bit.

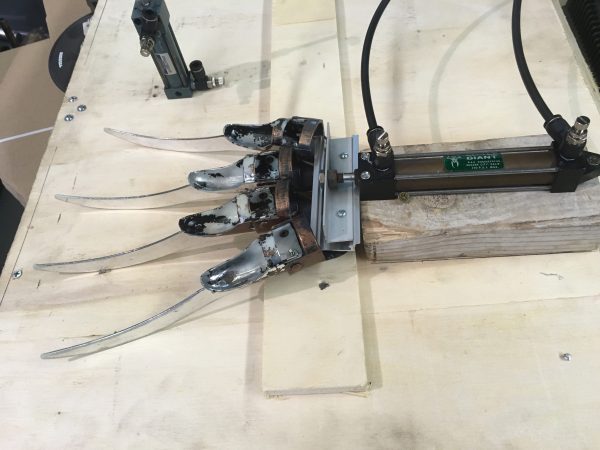

After a few ‘locked’ lid bounces, the cylinder retracts and the lid opens another couple of inches, giving the impression that creature broke the lock and is getting ready to escape. To add to the experience, when the lid pops up, a claw (from a Freddy Krueger costume) emerges from the gap in the open lid.

After a few ‘locked’ lid bounces, the cylinder retracts and the lid opens another couple of inches, giving the impression that creature broke the lock and is getting ready to escape. To add to the experience, when the lid pops up, a claw (from a Freddy Krueger costume) emerges from the gap in the open lid.

If that’s not enough excitement, the C-more HMI, displaying pictures of creepy eyes with simple animation to look like they are moving towards the audience, is mounted near the front of the box behind a small cage providing audio of growling, howling and snarling animals. While the PLC controls the pneumatic actions, the audio is triggered to play through a set of old PC speakers.

To provide a way to save energy when no one is around, and give a more realistic experience, retroreflective photoelectric sensors are used to bring the creature to life when someone approaches The Box.

Putting together this project was a lot of fun. The challenge was figuring out what could be put together with stuff that was sitting on shelves and in bins. I still wonder what I would have been doing for fun if that DURApulse VFD ‘Box’ hadn’t arrived at my shop.

Jay Rees, PE

“The Independent Integrator”

Rees Engineering Corp

Originally Pulbished: October 2016