Intelligent HMI advances can justify upgrades based on significant improvements associated with ease-of-use, cybersecurity, and other advanced features.

Consumers are accustomed to rapidly upgrading their personal electronic devices by buying new hardware and updating apps, but the industrial automation world usually works at a slower and more delayed pace in this regard. Greg Philbrook, HMI product manager at AutomationDirect, wrote an article for the December 2023 edition of InTech, titled HMIs Are Not iPhones: HMI Upgrade Considerations, covering some of the things that industrial users should look at when considering whether to specify an updated HMI for a new or retrofit application. Here’s a summary, click on the link above for the full text.

When is Newer Better?

To a great extent, modern industrial HMIs are quite mature products in terms of both hardware and software, but there remain several key aspects where users appreciate improvements:

- Ease-of-use

- Cybersecurity

- Future-proofing

- Convenient form factors

- Backward compatibility

- Practical new features

- Value

A typical consumer has a good amount of flexibility to choose the device size of their choice—usually going larger—when they select a phone or TV. But industrial users need consistent form-factors, even when transitioning from 4:3 display ratios to the new standard of 16:9, to preserve a degree of physical backward compatibility.

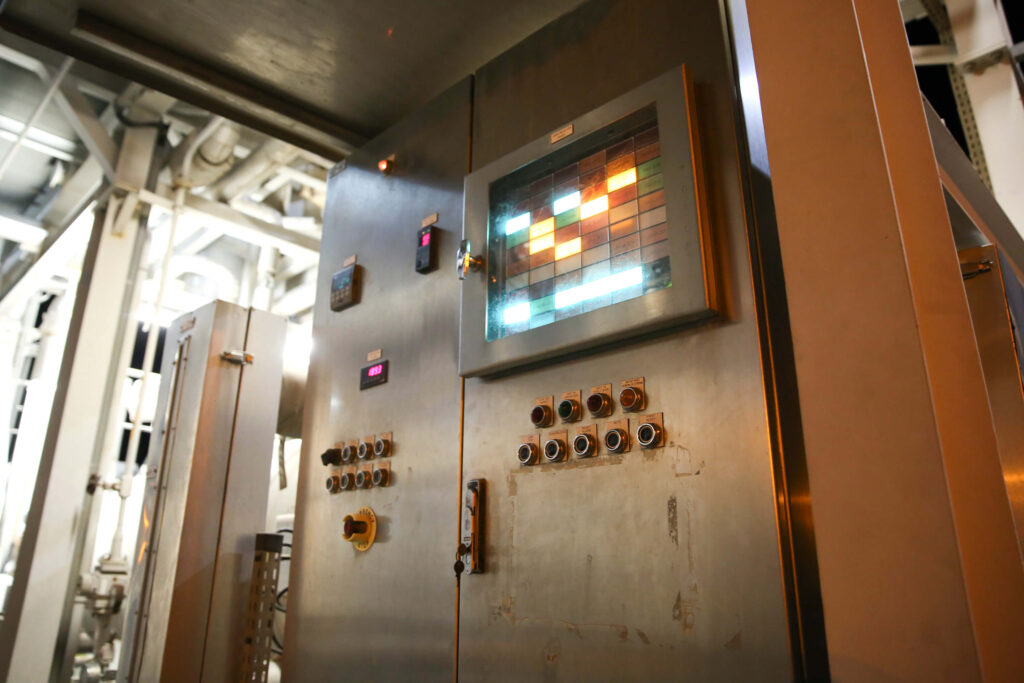

The newest CM5 generation of AutomationDirect C-more HMIs is designed with this in mind, and it is offered in 4-, 7-, 10-, 12-, 15-, and now also 22-inch sizes. These HMIs can run in landscape or portrait mode, and they continue to offer expected features, such as a NEMA 4/4X rating, 12/24VDC power inputs, serial ports, and SD card ports.

Beefed Up Behind the Scenes

Besides the ability to support legacy code for software backwards compatibility, the AutomationDirect CM5 C-more HMI series has other compelling features which may prompt users to move to the newest iteration:

- Network Time Protocol (NTP) support

- Secure communications, including SMTPS, HTTPS, and MQTTS

- Remote connectivity via web browser connections, a dedicated mobile app, FTP data transfer, and email

- Ability to act as a data bridge by aggregating data from several PLCs and/or HMIs

The AutomationDirect integrated development environment has always been known for exceptional ease-of-use, so users can get started quickly, and then minimize development time.

Industrial HMIs are a relatively mature part of the manufacturing and process automation landscape. However, experienced suppliers are working to make the upgrade path straightforward and secure to deliver maximum value and performance.

Whether you are developing a new “clean sheet” project, or looking to retrofit or upgrade an existing system, AutomationDirect has the HMIs and other products you need, and a support team ready to help.