ApplicationApplication StoriesAutomation NotebookData CollectionHMIIndustryIssue 7 – 2006Learning ResourcesManufacturingManufacturingNotebook IssueOperator InterfaceProductProgrammable ControlUser Solutions

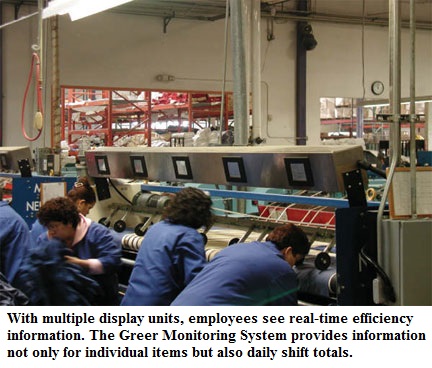

Improving Factory Workers’ Efficiency is All in a Name

As most everyone is aware, from a business standpoint, we live in a numbers-based society. In all businesses, whether a small company with a dozen employees or a large conglomerate of thousands, the focus is on the bottom line. Executives are scrutinizing annual, quarterly, monthly, weekly, and even daily reports to determine how productivity is…